Overview of Serum Anionic Bitumen Emulsion Machine Sauce Emulsifier Mixer for Lotion Small Scale Mixing Equipment

Anionic surfactants are a class of surface-active agents characterized by a negatively charged hydrophilic head group when dissolved in water. This charge arises from the presence of a sulfate, sulfonate, phosphate, or carboxylate group. They are among the most widely used surfactants due to their effective cleaning properties, foaming capacity, and broad compatibility with other formulation ingredients. Anionic surfactants find extensive application across industries, including personal care, household cleaning, textiles, and industrial processes.

Features of Serum Anionic Bitumen Emulsion Machine Sauce Emulsifier Mixer for Lotion Small Scale Mixing Equipment

-

Negative Charge: The anionic head group imparts water solubility and enables interaction with positively charged surfaces or particles.

-

Detergency: Exceptional at removing dirt, grease, and oils due to their strong polarity and ability to penetrate and disrupt these substances.

-

Foaming Properties: Many anionic surfactants generate stable and abundant foam, making them ideal for applications where lather is desired.

-

Cost-Effectiveness: They are often less expensive than nonionic, cationic, or amphoteric surfactants due to the abundance of raw materials and established production processes.

-

Compatibility: Can be combined with other surfactants to enhance performance or adjust properties, although care must be taken to avoid precipitation or incompatibility issues.

-

Environmental Considerations: Some anionic surfactants may pose environmental concerns due to their persistence or toxicity; however, biodegradable options are available.

(Serum Anionic Bitumen Emulsion Machine Sauce Emulsifier Mixer for Lotion Small Scale Mixing Equipment)

Specification of Serum Anionic Bitumen Emulsion Machine Sauce Emulsifier Mixer for Lotion Small Scale Mixing Equipment

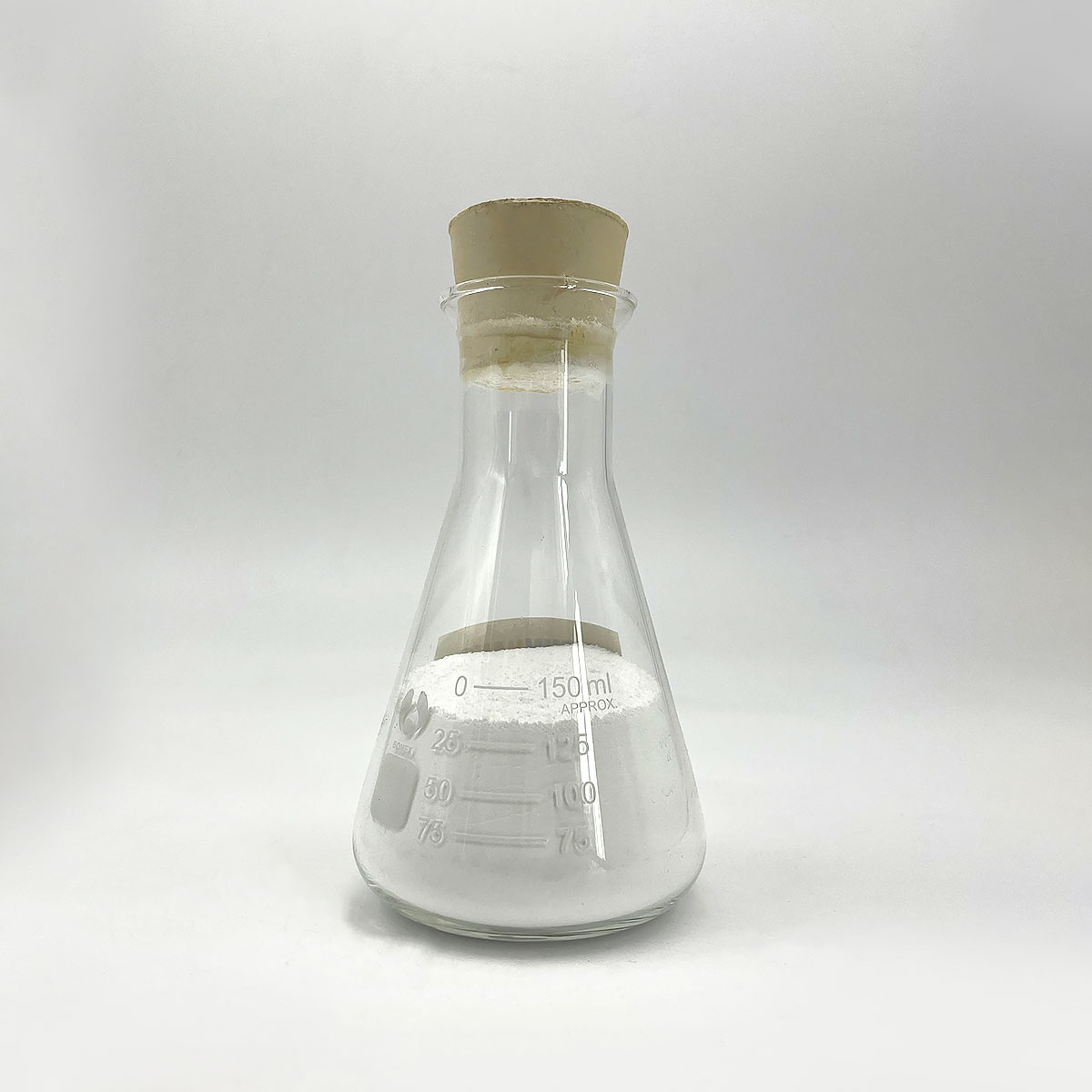

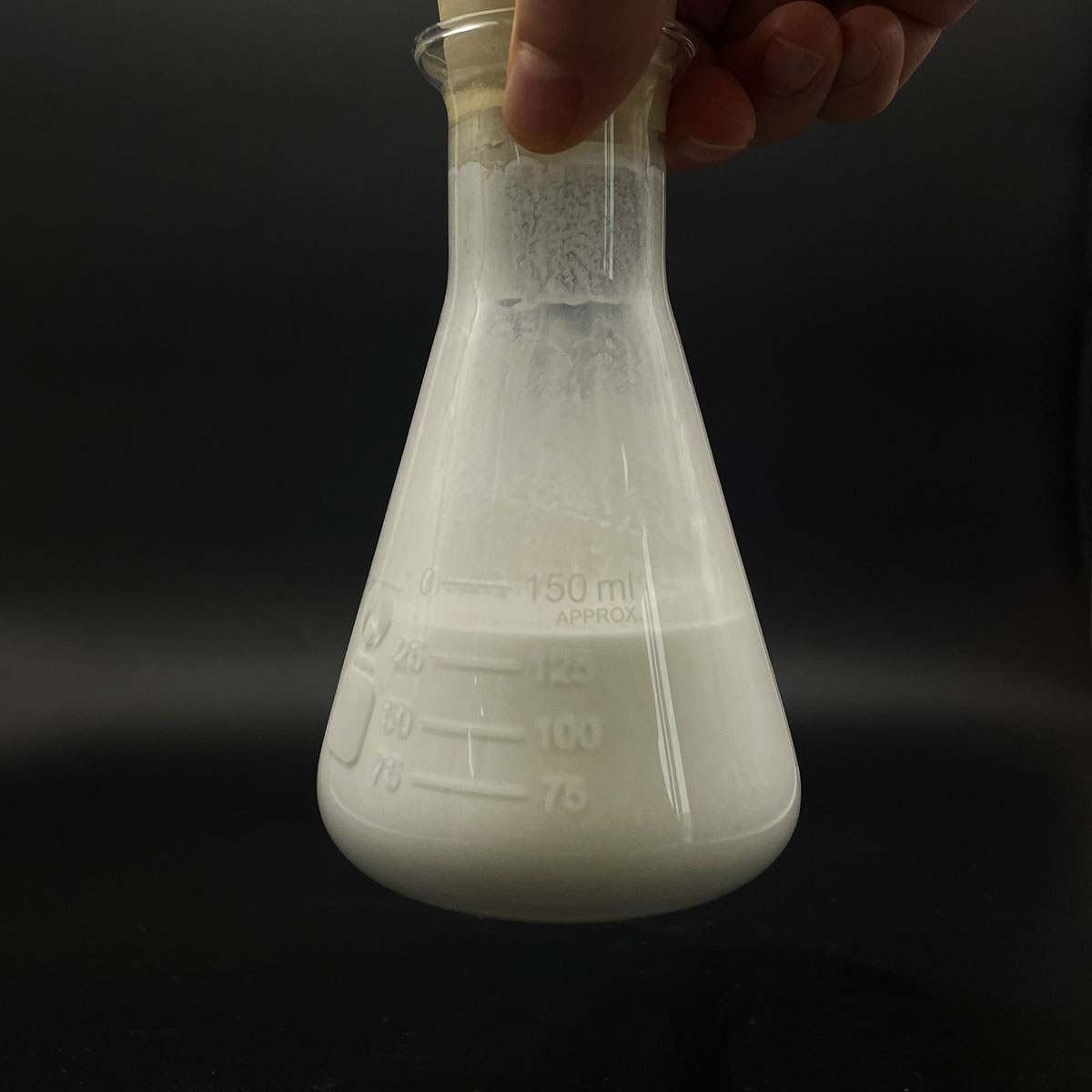

The Product Anionic Asphalt Solution Equipment Sauce Emulsifier Mixer is developed for small production of lotions, solutions, and comparable products. This tools combines high-shear blending innovation with specific control to ensure regular results. The machine handles bitumen-based solutions, cosmetic creams, and food-grade sauces. It fits labs, start-ups, and small factories needing trusted blending without massive financial investment.

The equipment makes use of a stainless-steel blending chamber. The chamber withstands rust and deals with aggressive chemicals. The motor power ranges from 1.5 kW to 3 kW, flexible for various thickness. The rotor-stator design develops fine, steady emulsions. The blades speed reaches up to 3000 RPM. Operators control rate manually or using a digital interface. The system consists of temperature level sensors to avoid overheating.

The emulsifier processes sets from 10 liters to 50 liters. The compact dimension saves room. The unit considers around 80 kg, making it movable with wheels. The inlet and outlet valves are stainless-steel. They enable easy loading and draining pipes. The maker works with single-phase or three-phase power. Voltage alternatives consist of 220V and 380V. Security attributes consist of overload protection and emergency quit switches.

Maintenance is simple. The mixing chamber disassembles without devices. Seals and gaskets are changeable. The device meets industrial hygiene criteria. Cleansing needs water or mild solvents. The layout prevents dead areas where product builds up.

Key applications include asphalt emulsion manufacturing for road building. It additionally blends cosmetic creams, pharmaceutical creams, and food sauces. Customers change blending time and speed for various structures. The high-shear action breaks down bits uniformly. This ensures smooth, stable solutions without swellings.

The maker minimizes power usage compared to typical mixers. Sound degrees remain listed below 70 decibels throughout operation. The sturdy structure reduces resonances. Optional devices include added blades, temperature control modules, and custom-made storage tank dimensions. Technical support covers installment, calibration, and troubleshooting.

The tools suits individuals prioritizing accuracy and longevity. It handles regular usage without efficiency loss. The design concentrates on customer security and item quality. Examining validates constant output across batches.

(Serum Anionic Bitumen Emulsion Machine Sauce Emulsifier Mixer for Lotion Small Scale Mixing Equipment)

Applications of Serum Anionic Bitumen Emulsion Machine Sauce Emulsifier Mixer for Lotion Small Scale Mixing Equipment

The serum anionic bitumen emulsion machine sauce emulsifier mixer is designed for small-scale mixing tasks. It handles lotion production efficiently. This equipment is ideal for creating stable emulsions in various industries. Construction and road maintenance sectors use it often. It mixes bitumen emulsions for asphalt repair and coating applications. The machine ensures even distribution of particles. This results in high-quality mixtures every time. The compact size makes it suitable for limited spaces. Small businesses and labs benefit from its portability. Users can adjust mixing speeds easily. Temperature control features prevent overheating. The design focuses on user safety and operational simplicity. Cleaning the machine takes minimal effort. Durable materials ensure long-term use without frequent repairs. The emulsifier mixer works with different viscosities. It handles both thick and thin solutions effectively. This flexibility supports diverse production needs. Waterproof coating manufacturers rely on it for consistent output. Adhesive producers use it to blend components accurately. The machine reduces waste by maintaining precise ratios. Energy efficiency lowers operational costs. It meets industry standards for performance and reliability. Operators with basic training can manage it without issues. The equipment integrates smoothly into existing production lines. Routine maintenance is straightforward. Replacement parts are widely available. The mixer’s anionic technology enhances emulsion stability. This prevents separation during storage or transport. Small-scale cosmetic producers use it for lotions and creams. The non-reactive surfaces ensure product purity. Mixing times are shorter compared to manual methods. Consistent results improve overall product quality. The machine is cost-effective for startups and small enterprises. It eliminates the need for large-scale investments. Customizable settings adapt to specific project requirements. The serum anionic bitumen emulsion machine is a practical solution for specialized mixing tasks. Its versatility makes it a valuable asset across multiple industries.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Serum Anionic Bitumen Emulsion Machine Sauce Emulsifier Mixer for Lotion Small Scale Mixing Equipment

Serum Anionic Bitumen Emulsion Machine Sauce Emulsifier Mixer for Lotion Small Scale Mixing Equipment solves precise blending needs. Below are common questions users ask.

What does this machine do? It mixes serum anionic bitumen emulsion with lotion ingredients. High-speed blades break down particles. Stable emulsions form quickly. Uniform texture matters for product quality.

How long does mixing take? Processing time depends on batch size. Small batches finish in 10-15 minutes. Larger volumes need 20-30 minutes. Temperature control prevents overheating. Consistency checks ensure results meet standards.

Is the machine easy to clean? Yes. Stainless steel parts resist corrosion. Disassemble components after use. Warm water and mild detergent remove residue. Drying parts before reassembly avoids contamination.

Can it handle thick or sticky materials? The motor adjusts speed for different viscosities. Thick sauces require slower mixing. Bitumen emulsions need higher speeds. The design prevents clogging.

What safety features are included? Emergency stop buttons halt operations instantly. Overload protection guards the motor. Non-slip feet keep the machine stable. Ventilation prevents fume buildup.

Does it work for small production runs? Yes. Compact size suits limited spaces. Precise controls manage tiny batches. Labs or startups find it ideal. Testing formulas becomes simpler.

Maintenance tips? Lubricate moving parts monthly. Inspect blades for wear every three months. Replace seals if leaks occur. Follow the manual for electrical checks.

(Serum Anionic Bitumen Emulsion Machine Sauce Emulsifier Mixer for Lotion Small Scale Mixing Equipment)