Overview of 80000cst Oh Polymer Raw Material Factory Directly ing

Polymer surfactants, also known as polymeric surfactants or amphiphilic polymers, are high-molecular-weight compounds that combine the properties of traditional low-molecular-weight surfactants with the unique features of polymers. Unlike small molecule surfactants, polymer surfactants offer enhanced stability, improved solubility, and the ability to form more complex structures such as micelles, hydrogels, and vesicles. These macromolecules find applications across a wide range of industries due to their tailored structures and tunable properties, which allow for precise control over interfacial behavior and solution rheology.

Features of 80000cst Oh Polymer Raw Material Factory Directly ing

-

Molecular Weight and Structure: With a much higher molecular weight, polymer surfactants offer enhanced stability in harsh conditions and over prolonged periods compared to small molecule surfactants.

-

Tunability: The structure of polymer surfactants can be precisely engineered to include different functional groups, monomer sequences, and architectures, allowing for specific interactions and properties.

-

Multifunctionality: Apart from surface activity, they can also provide additional functionalities like thickening, rheology modification, and controlled release capabilities.

-

Self-Assembly: Capable of forming sophisticated self-assembled structures like micelles, hydrogels, and vesicles, which can encapsulate or release active ingredients in a controlled manner.

-

Environmental Compatibility: Many polymer surfactants are designed to be biodegradable and less toxic, making them suitable for eco-friendly applications.

-

Temperature and pH Responsiveness: Some polymer surfactants exhibit responsive behavior to changes in temperature or pH, enabling stimuli-responsive systems.

(80000cst Oh Polymer Raw Material Factory Directly ing)

Specification of 80000cst Oh Polymer Raw Material Factory Directly ing

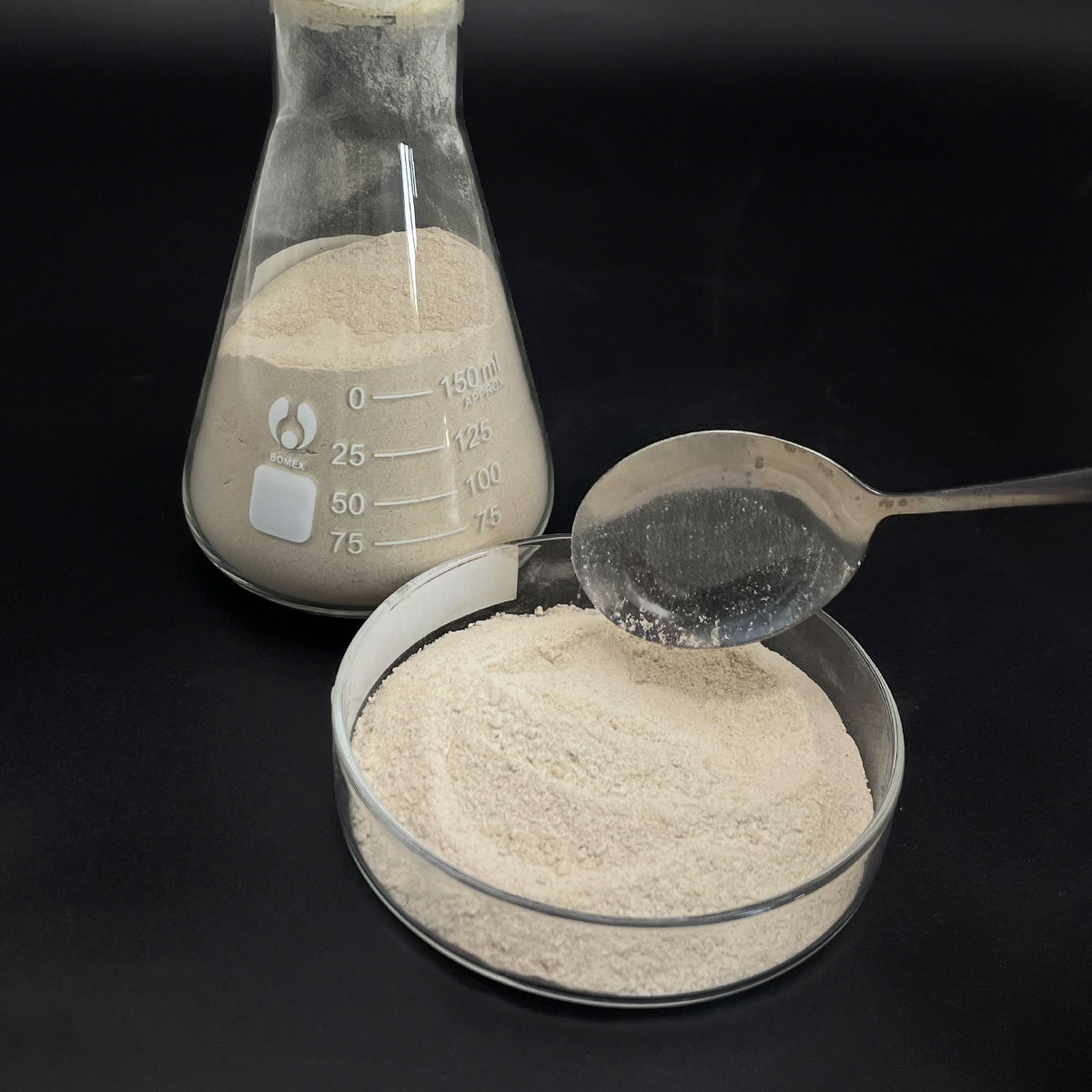

The 80000cst OH Polymer Raw Material is a high-viscosity industrial-grade item developed for several applications. It has a regular viscosity ranking of 80000 centistokes, making certain steady efficiency popular settings. The material keeps chemical stability, resisting responses with oils, solvents, and acids. This makes it ideal for long-term usage without deterioration. It manages heats without breaking down, operating properly in varieties from -40 ° C to

200 ° C. The polymer basic material is produced under rigorous quality assurance actions. Factories utilize advanced synthesis techniques to make sure harmony in every batch. It can be found in a semi-transparent, unsmelling type with very little impurities. The item fulfills worldwide standards for commercial materials, consisting of ISO accreditations.

This product is suitable for creating lubricating substances, sealers, and damping liquids. It improves product longevity in automobile parts, equipment, and digital components. Makers value its ability to minimize friction and take in resonances. It likewise works as a base for specialty coatings, supplying water resistance and adaptability.

Provided directly from manufacturing facilities, the raw material cuts costs for bulk customers. Customized orders are readily available for specific thickness modifications or additive blends. The manufacturing procedure minimizes waste, aligning with environment-friendly methods. Packaging choices consist of drums, totes, or custom-made containers to fit logistics requirements.

Security is focused on throughout handling and storage. The material is non-toxic and non-flammable under typical problems. Employees must utilize fundamental protective gear like gloves and safety glasses. Storage space calls for a dry, amazing environment away from direct sunshine. Correct sealing protects against contamination and prolongs life span.

Compliance with global policies like REACH and RoHS ensures compatibility with international markets. Technical support is provided for combination into assembly line. Checking examples are readily available to verify efficiency prior to large-scale orders. The product’s dependability makes it a favored selection for sectors seeking efficiency and cost-effectiveness.

(80000cst Oh Polymer Raw Material Factory Directly ing)

Applications of 80000cst Oh Polymer Raw Material Factory Directly ing

The 80000cst OH polymer raw material is a high-viscosity product made in factories for straight industrial usage. Its highlight is a hydroxyl value that enables strong bonding with other compounds. This makes it useful in many areas. One essential use is in adhesives. The polymer produces resilient bonds in items like tapes, tags, and building and construction adhesives. It remains versatile under stress and anxiety, protecting against cracks or breaks.

One more typical application is sealants. The material resists water, heat, and chemicals. It works well in securing joints, voids, or joints in buildings, automobiles, or electronic devices. The high thickness makes sure long-lasting protection against leakages.

Coatings benefit from this polymer as well. Blended with ingredients, it forms safety layers on surface areas. These coverings guard against wear, rust, or UV damage. Industries utilize it on metal parts, floor covering, or exterior equipment.

In individual treatment, the polymer readjusts appearance in products like lotions or hair gels. It thickens solutions without making them sticky. This improves just how items really feel and do.

Industrial lubricating substances additionally utilize this product. Its thickness decreases rubbing in machinery components. Manufacturing facilities use it in gears, hydraulics, or hefty equipment for smoother procedure.

Automotive components rely on the polymer for vibration dampening. It soaks up shocks in engine installs or interior panels. This decreases sound and expands component life.

Construction materials like caulks or insulation foams make use of the polymer for elasticity. It manages temperature level shifts without losing shape.

Manufacturing facilities making this polymer guarantee tight quality control. Direct supply cuts expenses and quicken delivery. Custom qualities are available for specific demands.

The product satisfies security and environmental requirements. It works in environmentally friendly products because of low toxicity.

No final thought required.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of 80000cst Oh Polymer Raw Material Factory Directly ing

What is 80000cst OH Polymer Raw Material? This material is a high-viscosity polymer used in industrial applications. It is designed for products needing thickness and elasticity. The factory produces it directly, ensuring quality control and cost efficiency. The “80,000cst” refers to its viscosity measurement, indicating its flow resistance under stress. Industries like adhesives, sealants, and coatings commonly use it.

Where is this material typically used? It is used in products requiring heavy-duty performance. Examples include industrial adhesives for construction, automotive sealants, and protective coatings. Lubricants and damping fluids in machinery also use this polymer. Electronics manufacturers apply it for insulation. Medical devices sometimes incorporate it for shock absorption.

Why choose a viscosity of 80,000 cst? Higher viscosity provides better stability in extreme conditions. Thicker materials resist separation under heat or pressure. This makes the polymer ideal for long-lasting applications. Products maintain performance in high-stress environments. Lower viscosity materials may fail under similar conditions.

How does your product differ from competitors? The factory controls production from raw materials to final packaging. This reduces costs and ensures consistency. Competitors often rely on third-party suppliers, risking quality variations. Our material undergoes strict testing for purity and performance. Technical support is available directly from production experts.

Can I request a sample before bulk orders? Samples are available for quality verification. Testing the material in your specific application is encouraged. Custom adjustments can be made based on sample feedback. Bulk orders are produced after sample approval. This ensures the product meets your exact requirements.

(80000cst Oh Polymer Raw Material Factory Directly ing)