Overview of Hydroxyl Terminated Polydimethylsiloxane Silanol Terminated Pdms/Polymer Oh

Polymer surfactants, also known as polymeric surfactants or amphiphilic polymers, are high-molecular-weight compounds that combine the properties of traditional low-molecular-weight surfactants with the unique features of polymers. Unlike small molecule surfactants, polymer surfactants offer enhanced stability, improved solubility, and the ability to form more complex structures such as micelles, hydrogels, and vesicles. These macromolecules find applications across a wide range of industries due to their tailored structures and tunable properties, which allow for precise control over interfacial behavior and solution rheology.

Features of Hydroxyl Terminated Polydimethylsiloxane Silanol Terminated Pdms/Polymer Oh

-

Molecular Weight and Structure: With a much higher molecular weight, polymer surfactants offer enhanced stability in harsh conditions and over prolonged periods compared to small molecule surfactants.

-

Tunability: The structure of polymer surfactants can be precisely engineered to include different functional groups, monomer sequences, and architectures, allowing for specific interactions and properties.

-

Multifunctionality: Apart from surface activity, they can also provide additional functionalities like thickening, rheology modification, and controlled release capabilities.

-

Self-Assembly: Capable of forming sophisticated self-assembled structures like micelles, hydrogels, and vesicles, which can encapsulate or release active ingredients in a controlled manner.

-

Environmental Compatibility: Many polymer surfactants are designed to be biodegradable and less toxic, making them suitable for eco-friendly applications.

-

Temperature and pH Responsiveness: Some polymer surfactants exhibit responsive behavior to changes in temperature or pH, enabling stimuli-responsive systems.

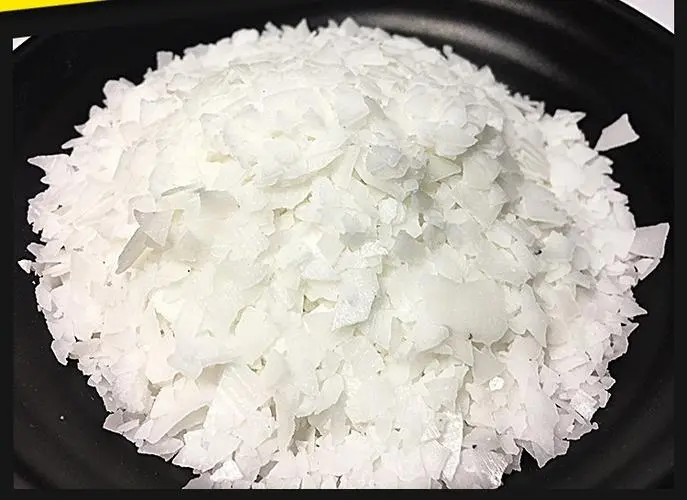

(Hydroxyl Terminated Polydimethylsiloxane Silanol Terminated Pdms/Polymer Oh)

Specification of Hydroxyl Terminated Polydimethylsiloxane Silanol Terminated Pdms/Polymer Oh

Hydroxyl Terminated Polydimethylsiloxane (Silanol Terminated PDMS/Polymer OH) is a silicone-based polymer with unique properties. It is widely used in industries like coatings, adhesives, electronics, and medical devices. The product has a flexible backbone structure made of repeating dimethylsiloxane units. Its hydroxyl (-OH) end groups enable reactivity, making it ideal for cross-linking or modifying other materials.

The molecular weight typically ranges between 500 and 100,000 g/mol. This range allows customization for different applications. The viscosity varies from 10 to 1,000,000 centipoise (cP). Lower viscosity grades flow easily for coatings. Higher viscosity grades provide thickening effects in gels or rubbers. The hydroxyl content is between 0.1% and 10% by weight. Higher hydroxyl levels boost reactivity for chemical bonding.

The material appears as a clear, colorless liquid or semi-solid. It remains stable at temperatures from -50°C to 200°C. This thermal stability suits high-heat environments. It resists oxidation, UV radiation, and moisture. These traits ensure long-term durability. The density is around 0.97 to 1.00 g/cm³. It dissolves in common solvents like toluene, xylene, or hexane. This aids formulation processes.

The polymer is chemically inert. It does not react with most substances. This prevents contamination in sensitive applications. It has low surface tension. This allows it to spread evenly on substrates. The material is non-toxic. It meets safety standards for medical and food-grade uses.

Applications include sealants for electronics, where flexibility and insulation matter. It acts as a release agent in molding processes. It modifies rubbers to enhance elasticity. In cosmetics, it adds smoothness to creams. For adhesives, it improves bonding strength. The polymer works as a defoamer in industrial fluids.

Storage requires keeping it sealed in a dry, cool place. Exposure to moisture causes premature curing. Shelf life is up to 12 months under proper conditions. Compatibility testing is recommended before mixing with other chemicals. This ensures optimal performance.

(Hydroxyl Terminated Polydimethylsiloxane Silanol Terminated Pdms/Polymer Oh)

Applications of Hydroxyl Terminated Polydimethylsiloxane Silanol Terminated Pdms/Polymer Oh

Hydroxyl Terminated Polydimethylsiloxane Silanol Terminated PDMS/Polymer OH is a versatile silicone-based material used across many industries. Its reactive hydroxyl and silanol groups allow it to bond with other compounds. This makes it valuable for creating durable, flexible products.

In adhesives and sealants, this polymer improves performance. It forms strong bonds that stay flexible under stress. It works in high-temperature environments. It resists moisture, chemicals, and UV exposure. These traits make it ideal for automotive and aerospace applications.

The construction industry uses it in weatherproofing sealants. It seals gaps in windows, roofs, and joints. It prevents leaks while allowing materials to expand and contract. Its durability ensures long-term protection against harsh weather.

Medical devices benefit from its biocompatibility. It is safe for skin contact and implants. It is used in tubing, catheters, and wound care products. Its flexibility and stability ensure reliable performance in sensitive applications.

In cosmetics, it creates smooth textures. It blends into lotions, creams, and hair products. It spreads evenly without greasiness. It enhances product feel and longevity.

Electronics manufacturing relies on it for protective coatings. It insulates circuits and components. It shields against moisture, dust, and heat. This extends the lifespan of devices like sensors and circuit boards.

Textile treatments use this polymer to add water resistance. It coats fabrics for outdoor gear and sportswear. It keeps materials breathable while repelling water.

Industrial coatings incorporate it for corrosion protection. It is applied to machinery, pipelines, and metal surfaces. It reduces wear and tear from chemicals and friction.

The automotive sector uses it in gaskets, hoses, and vibration dampers. It handles engine heat and road chemicals. It maintains flexibility in extreme temperatures.

This polymer’s adaptability ensures it meets diverse needs. It combines silicone’s benefits with reactive functionality. Industries choose it for reliability, safety, and performance.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Hydroxyl Terminated Polydimethylsiloxane Silanol Terminated Pdms/Polymer Oh

Hydroxyl Terminated Polydimethylsiloxane (PDMS) Silanol Terminated PDMS/Polymer OH is a silicone-based polymer with reactive hydroxyl groups. It serves industries like adhesives, coatings, and electronics. Below are answers to common questions about this material.

What is Hydroxyl Terminated Polydimethylsiloxane?

This polymer is a silicone chain with hydroxyl (-OH) groups at both ends. These groups make it reactive. The structure provides flexibility, heat resistance, and water repellency. It is used in products needing durable, stable performance.

Where is it commonly applied?

It is used in sealants, adhesives, and lubricants. Electronics manufacturers use it for potting or encapsulating components. Medical device makers apply it for biocompatible coatings. Industrial coatings use it for weatherproofing.

Is it safe to handle?

Wear gloves and goggles when using it. Avoid skin contact or inhaling vapors. Work in a ventilated area. Follow safety guidelines from the supplier. Improper handling can cause irritation.

How should it be stored?

Store it in a cool, dry place away from sunlight. Keep containers tightly sealed. Moisture can degrade its quality. Check expiration dates. Do not mix with incompatible chemicals before use.

How does it differ from regular PDMS?

Regular PDMS lacks reactive hydroxyl groups. This version bonds better with other materials. It forms stronger networks in adhesives or coatings. The reactivity makes it ideal for custom formulations needing precise curing.

The material’s versatility comes from its balance of stability and reactivity. Users must prioritize safety and storage to maintain performance. Compatibility testing is recommended for new applications.

(Hydroxyl Terminated Polydimethylsiloxane Silanol Terminated Pdms/Polymer Oh)