Overview of Silicone Oil Polyurethane L580 Silicone Surfactant for PU Flexible Foam

Polymer surfactants, also known as polymeric surfactants or amphiphilic polymers, are high-molecular-weight compounds that combine the properties of traditional low-molecular-weight surfactants with the unique features of polymers. Unlike small molecule surfactants, polymer surfactants offer enhanced stability, improved solubility, and the ability to form more complex structures such as micelles, hydrogels, and vesicles. These macromolecules find applications across a wide range of industries due to their tailored structures and tunable properties, which allow for precise control over interfacial behavior and solution rheology.

Features of Silicone Oil Polyurethane L580 Silicone Surfactant for PU Flexible Foam

-

Molecular Weight and Structure: With a much higher molecular weight, polymer surfactants offer enhanced stability in harsh conditions and over prolonged periods compared to small molecule surfactants.

-

Tunability: The structure of polymer surfactants can be precisely engineered to include different functional groups, monomer sequences, and architectures, allowing for specific interactions and properties.

-

Multifunctionality: Apart from surface activity, they can also provide additional functionalities like thickening, rheology modification, and controlled release capabilities.

-

Self-Assembly: Capable of forming sophisticated self-assembled structures like micelles, hydrogels, and vesicles, which can encapsulate or release active ingredients in a controlled manner.

-

Environmental Compatibility: Many polymer surfactants are designed to be biodegradable and less toxic, making them suitable for eco-friendly applications.

-

Temperature and pH Responsiveness: Some polymer surfactants exhibit responsive behavior to changes in temperature or pH, enabling stimuli-responsive systems.

(Silicone Oil Polyurethane L580 Silicone Surfactant for PU Flexible Foam)

Specification of Silicone Oil Polyurethane L580 Silicone Surfactant for PU Flexible Foam

L580 Silicone Surfactant is a silicone oil polyurethane additive made for flexible polyurethane foam manufacturing. It maintains foam formation, boosts cell structure uniformity, and enhances foam physical residential or commercial properties. The product operates in slabstock, formed, and rebonded foam processes. It stabilizes surface stress during frothing to stop collapse or contraction.

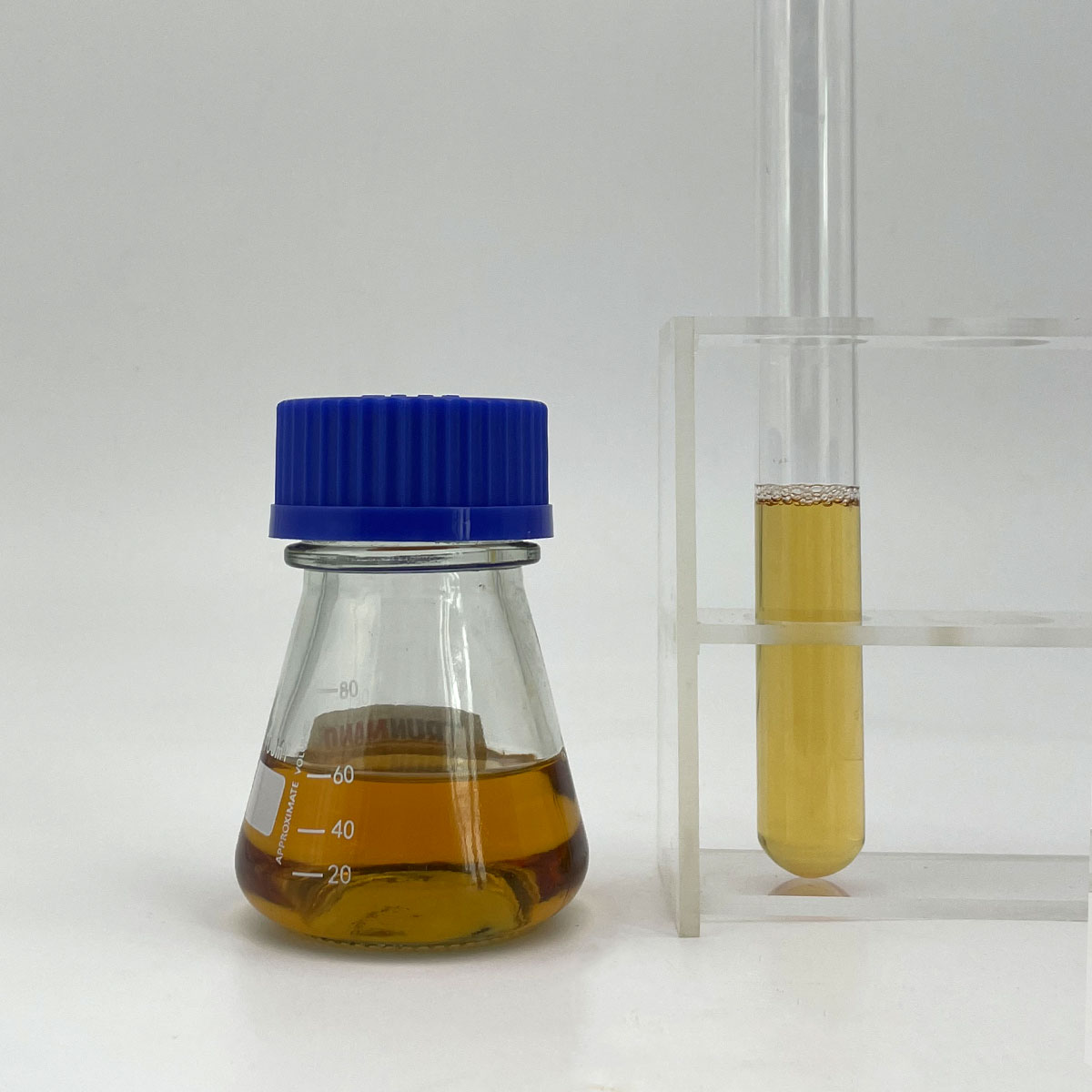

The surfactant is a clear, light-yellow liquid. It is soluble in polyols and suitable with typical foam ingredients like isocyanates, catalysts, and fire retardants. Its viscosity ranges in between 1,000 to 2,500 mPa · s at 25 ° C. The thickness is around 1.02 g/cm ³. The item continues to be steady under typical storage conditions. Maintain it sealed in a dry, cool location away from straight sunlight. Shelf life is 12 months from manufacturing.

L580 changes cell visibility in versatile foams. This guarantees constant air movement and convenience in end products. It minimizes surface area issues like pinholes or voids during foam expansion. The surfactant supports sluggish reaction systems. It preserves foam integrity when handling delays happen.

Common use degrees vary from 0.5 to 2.5 components per hundred parts of polyol. Readjust dosage based on foam formula and device specifications. Examination small batches initially to maximize efficiency. The item deals with water-blown, HCFC-free, and low-VOC systems. It does not interfere with fire resistance or various other foam ingredients.

Applications consist of bed mattress, upholstered furnishings, child seat cushions, and acoustic insulation. The surfactant improves foam longevity. It decreases solidifying gradually. Foam manufacturers accomplish greater yield and lower waste prices. Handling tools stays cleaner because of minimized residue accumulation.

The product satisfies sector standards for versatile PU foam additives. It is devoid of unsafe materials like hefty metals or outlawed silicones. Manage it utilizing typical PPE– handwear covers and safety glasses. Stay clear of skin get in touch with or breathing throughout use. Dispose of vacant containers according to regional regulations.

Foam suppliers like L580 for its integrity throughout different manufacturing conditions. It simplifies repairing in unsteady lathering environments. The surfactant adapts to temperature or humidity fluctuations. It maintains performance in both high-density and low-density foam recipes.

(Silicone Oil Polyurethane L580 Silicone Surfactant for PU Flexible Foam)

Applications of Silicone Oil Polyurethane L580 Silicone Surfactant for PU Flexible Foam

Silicone Oil Polyurethane L580 Silicone Surfactant plays an essential role in generating PU adaptable foam. This item maintains foam during manufacturing. It manages cell framework to make sure uniformity. The result is top quality foam with regular performance.

PU adaptable foam needs precise cell formation. L580 minimizes surface area stress in the liquid combination. This permits gas bubbles to spread evenly. Without appropriate stabilization, foam cells may collapse or merge. L580 avoids this problem. It creates a balanced network of cells. The foam maintains its shape and framework.

The surfactant enhances foam gentleness and longevity. It boosts comfort in finished products. Furnishings manufacturers make use of L580 for pillows and furniture. The foam stays durable under duplicated usage. Mattress producers benefit from constant appearance. The material adapts to body shapes without sagging. Automotive seating relies upon L580 for assistance and temperature resistance. The foam withstands varying conditions inside lorries.

L580 works well in various manufacturing setups. It adjusts to various foam densities. Manufacturers accomplish wanted suppleness degrees conveniently. The surfactant accelerate the treating procedure. This minimizes total production time. It likewise reduces problems like voids or irregular surfaces.

Other applications consist of product packaging and sporting activities tools. Safety packaging requires light-weight yet durable foam. L580 makes certain shock absorption without adding bulk. Sports equipment like yoga mats get far better hold and cushioning. The foam stays versatile in cool or hot atmospheres.

The surfactant works with several foam solutions. It blends efficiently with various other chemicals. This simplifies the production process. Workers manage it safely because of reduced toxicity. Storage and handling require very little preventative measures.

Making use of L580 lowers waste prices. Fewer sets obtain declined for quality concerns. Manufacturers save costs while maintaining high criteria. Completion product meets sector needs for safety and performance. Customers receive dependable foam remedies for diverse requirements.

L580 supports environment-friendly methods. It reduces energy usage throughout production. The effective procedure reduce resource usage. Companies satisfy sustainability objectives without sacrificing item high quality.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Silicone Oil Polyurethane L580 Silicone Surfactant for PU Flexible Foam

Silicone Oil Polyurethane L580 Silicone Surfactant for PU Flexible Foam addresses common production challenges. Here are five FAQs. What is the main function of L580? It stabilizes foam during formation. The surfactant balances foam structure by controlling cell size. It prevents uneven cells or collapse. This ensures consistent foam quality. How does L580 improve foam softness? The product adjusts surface tension in the liquid mix. This creates smaller, more uniform cells. The result is softer, more flexible foam with better durability. Users notice improved comfort in final products. What is the recommended dosage for L580? Typical use ranges from 1.0 to 2.5 parts per hundred parts polyol. Exact amounts depend on foam density and system components. Testing small batches first is advised. Adjustments may be needed based on machine settings or environmental conditions. Can L580 work with other additives? Yes. It is compatible with most polyols, catalysts, and blowing agents. No conflicts with standard flame retardants or colorants are observed. Check compatibility if using uncommon additives. Mixing order might affect performance. Add L580 early in the blending process for best results. How should L580 be stored? Keep containers tightly sealed. Store in a dry area below 30°C. Avoid direct sunlight or freezing temperatures. Moisture contamination causes clumping. Use opened containers within six months. Unused material should not be returned to original packaging.

(Silicone Oil Polyurethane L580 Silicone Surfactant for PU Flexible Foam)