Overview of Top Quality White Powder Polyvinyl Chloride Resin Sg5 CAS 9002-86-2 with Good

Specialty surfactants are a diverse class of surface-active agents designed for specific, high-performance applications where standard surfactants may not meet the required performance criteria. These surfactants are often tailor-made to exhibit unique properties, such as extreme temperature stability, low foam formation, high solubility in specific solvents, or compatibility with particular chemical systems. They are crucial components in formulations demanding precision, enhanced functionality, or strict regulatory compliance, found across industries from pharmaceuticals to advanced materials manufacturing.

Features of Top Quality White Powder Polyvinyl Chloride Resin Sg5 CAS 9002-86-2 with Good

-

Customized Performance: Developed to meet exacting specifications, offering tailored functionalities beyond generic surfactants.

-

High Efficiency: Designed to work at lower concentrations or under challenging conditions, increasing performance per unit mass.

-

Unique Properties: May exhibit special traits such as non-flammability, low toxicity, high thermal stability, or specific solubility profiles.

-

Regulatory Compliance: Often formulated to meet stringent industry-specific regulations, such as food-grade, medical, or eco-friendly standards.

-

Innovative Chemistry: Incorporate novel chemistries, such as fluorinated, silicone-based, or bio-based structures, to achieve specialized performance.

-

Synergistic Effects: Frequently used in combination with other surfactants to enhance or augment performance in complex formulations.

(Top Quality White Powder Polyvinyl Chloride Resin Sg5 CAS 9002-86-2 with Good )

Specification of Top Quality White Powder Polyvinyl Chloride Resin Sg5 CAS 9002-86-2 with Good

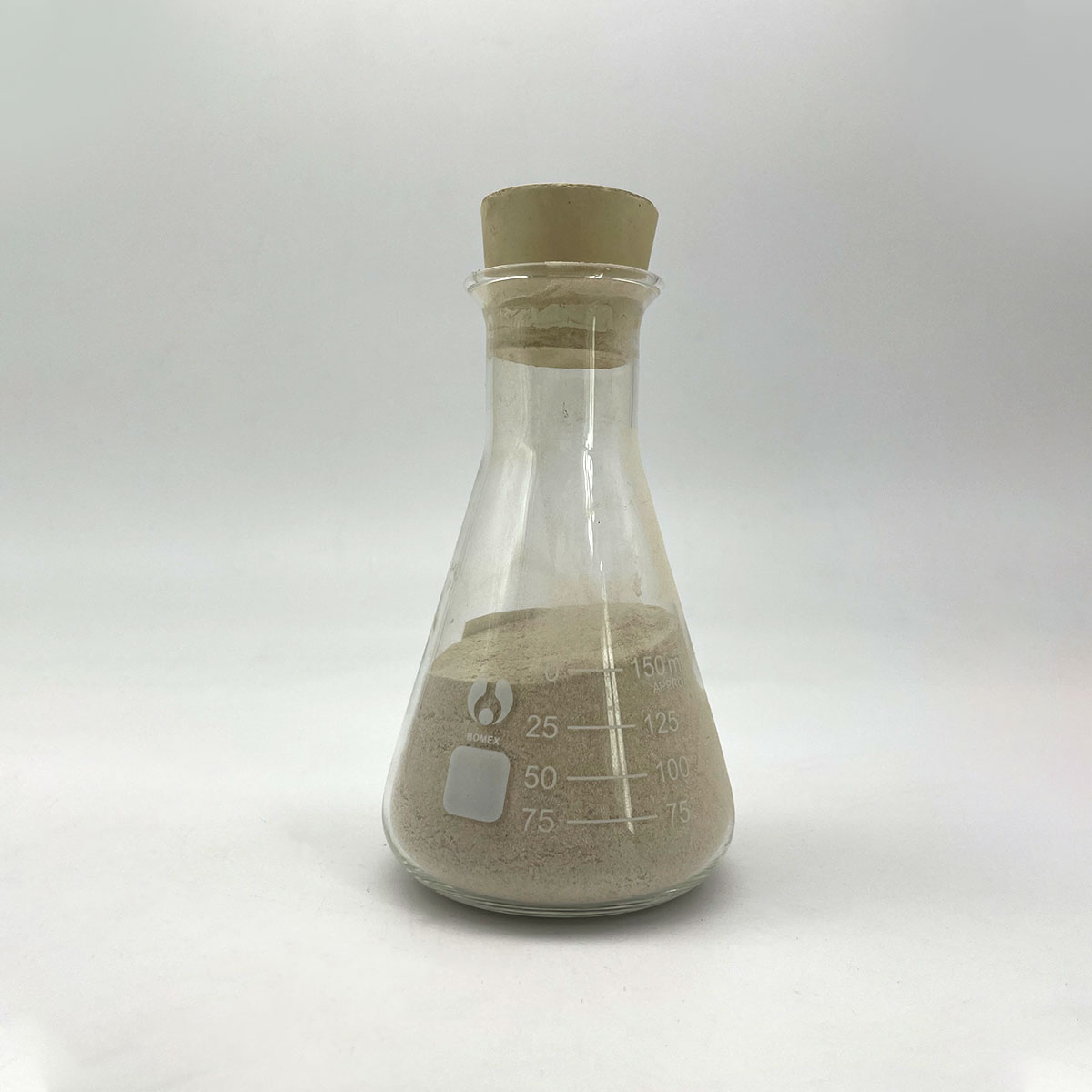

Top Quality White Powder Polyvinyl Chloride Material SG5 CAS 9002-86-2 is a high-performance material widely used in commercial applications. It appears as a fine white powder with consistent fragment circulation. The product has a high purity level, making certain consistent performance in numerous processes. Its chemical stability makes it ideal for long-lasting usage in different settings. The resin stands up to chemicals well, consisting of acids, alkalis, and salts. This home aids keep structural integrity in harsh conditions.

The material shows exceptional thermal resistance, handling temperatures up to 60 ° C without deterioration. It maintains versatility at reduced temperature levels, protecting against brittleness. This equilibrium makes it perfect for items exposed to varying climates. The material’s low electric conductivity improves its usage in insulation applications. It is frequently used in pipelines, cords, window profiles, and artificial leather. Manufacturers choose it for creating stiff and semi-rigid items.

Handling the resin is uncomplicated. It deals with techniques like extrusion, injection molding, and calendering. The powder streams efficiently throughout production, decreasing power usage. This performance decreases manufacturing expenses while keeping quality. The product’s compatibility with ingredients permits modification. Plasticizers, stabilizers, or pigments can be mixed to satisfy details needs.

Fragment size is controlled snugly, averaging in between 100 and 150 microns. This consistency guarantees also melting and mixing during processing. The product’s bulk density ranges from 0.45 to 0.55 g/cm ³, enhancing handling and storage. Packaging options include 25kg moisture-proof bags or personalized containers. Proper storage in completely dry, cool problems prolongs service life.

Security requirements are satisfied completely. The resin adheres to worldwide guidelines for industrial products. Individuals need to comply with basic dealing with procedures to stay clear of breathing or contact with skin. It is non-flammable but needs ventilation in handling areas. Quality assurance checks happen at every manufacturing stage. Each batch undertakes testing for thickness, volatility, and thermal security. This ensures reputable performance across applications.

The product offers industries like building and construction, vehicle, and electronic devices. Its sturdiness and flexibility make it a preferred choice for designers. Suppliers value its cost-effectiveness and constant results. Technical support is available to help with application-specific queries. Samples can be offered testing prior to large orders.

(Top Quality White Powder Polyvinyl Chloride Resin Sg5 CAS 9002-86-2 with Good )

Applications of Top Quality White Powder Polyvinyl Chloride Resin Sg5 CAS 9002-86-2 with Good

Premium White Powder Polyvinyl Chloride Material SG5 (CAS 9002-86-2) is a flexible product commonly utilized across industries. This PVC resin is understood for its longevity, chemical resistance, and convenience of processing. It serves as a key component in manufacturing rigid and flexible products.

The building and construction field depends on SG5 PVC material for pipes, installations, and window accounts. The product endures rough weather condition and chemical exposure. It ensures long-lasting performance in pipes and drain systems. Home builders prefer it for its lightweight nature and reduced upkeep needs.

In the automotive market, SG5 material is made use of for wire insulation, interior panels, and furniture. It resists warm and abrasion, making it suitable for automobile components. Cars and truck suppliers value its ability to reduce weight while maintaining safety and security standards.

The product packaging industry utilizes this material to produce films, sheets, and sore packs. It gives clarity and flexibility, shielding items throughout storage and transport. Food-grade versions fulfill hygiene criteria for covering subject to spoiling things.

Electronics suppliers apply SG5 PVC material for wire coatings and insulation. It avoids electric leakage and shields against environmental damages. Its flame-retardant properties boost security in tools and wiring systems.

Clinical tools manufacturers utilize this material for non reusable tubing, IV bags, and tool real estates. It complies with rigorous wellness policies. The material’s non-reactive nature guarantees compatibility with delicate medical applications.

SG5 PVC resin is refined via extrusion, shot molding, or calendering. It blends quickly with stabilizers, plasticizers, and pigments. This allows modification for certain efficiency needs. Factories appreciate its cost-effectiveness and minimal waste generation.

The material’s white powder type makes certain uniform blending and regular end-product high quality. It satisfies global criteria for industrial and consumer applications. Vendors focus on high-purity sets to prevent contamination dangers.

Organizations select SG5 PVC resin for its reliability and flexibility. It supports lasting practices by enabling recyclable product layouts. Global need continues to grow as industries look for effective, resilient products.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Top Quality White Powder Polyvinyl Chloride Resin Sg5 CAS 9002-86-2 with Good

1. What is White Powder Polyvinyl Chloride Resin SG5 used for? This resin is mainly used to make rigid PVC products. Common applications include pipes, window profiles, sheets, bottles, cables. It works well in construction materials, packaging, automotive parts. The material offers good durability, chemical resistance, easy processing.

2. Why is this PVC resin called “top quality”? The resin meets strict production standards. It has high purity, uniform particle size, stable viscosity. These features ensure consistent performance during manufacturing. It passes tests for thermal stability, electrical insulation, mechanical strength. No impurities affect product quality.

3. How should this PVC resin be stored? Keep it in a dry, cool place. Avoid direct sunlight, moisture, high temperatures above 50°C. Use sealed containers to prevent contamination. Keep away from strong oxidizers, acids, alkalis. Proper storage maintains its properties for up to 12 months.

4. Are there safety precautions for handling this resin? Wear gloves, goggles, masks during use. Avoid breathing dust. Ensure good ventilation in workspaces. The resin itself is non-flammable but may release fumes if overheated. Follow local disposal rules for waste material.

5. What technical specs define PVC Resin SG5? The CAS number is 9002-86-2. Appearance is white powder. K-value ranges 66-68. Bulk density is 0.48-0.52 g/cm³. Volatile content stays below 0.4%. Particle size passes 98% through 40 mesh sieve. Ash content remains under 0.1%.

(Top Quality White Powder Polyvinyl Chloride Resin Sg5 CAS 9002-86-2 with Good )