Overview of 02-Surfactant for Hydraulic Fracturing Stimulation Polymer Fracturing Fluid System Surface Tention and Interfacial Tention Reduction

Polymer surfactants, also known as polymeric surfactants or amphiphilic polymers, are high-molecular-weight compounds that combine the properties of traditional low-molecular-weight surfactants with the unique features of polymers. Unlike small molecule surfactants, polymer surfactants offer enhanced stability, improved solubility, and the ability to form more complex structures such as micelles, hydrogels, and vesicles. These macromolecules find applications across a wide range of industries due to their tailored structures and tunable properties, which allow for precise control over interfacial behavior and solution rheology.

Features of 02-Surfactant for Hydraulic Fracturing Stimulation Polymer Fracturing Fluid System Surface Tention and Interfacial Tention Reduction

-

Molecular Weight and Structure: With a much higher molecular weight, polymer surfactants offer enhanced stability in harsh conditions and over prolonged periods compared to small molecule surfactants.

-

Tunability: The structure of polymer surfactants can be precisely engineered to include different functional groups, monomer sequences, and architectures, allowing for specific interactions and properties.

-

Multifunctionality: Apart from surface activity, they can also provide additional functionalities like thickening, rheology modification, and controlled release capabilities.

-

Self-Assembly: Capable of forming sophisticated self-assembled structures like micelles, hydrogels, and vesicles, which can encapsulate or release active ingredients in a controlled manner.

-

Environmental Compatibility: Many polymer surfactants are designed to be biodegradable and less toxic, making them suitable for eco-friendly applications.

-

Temperature and pH Responsiveness: Some polymer surfactants exhibit responsive behavior to changes in temperature or pH, enabling stimuli-responsive systems.

(02-Surfactant for Hydraulic Fracturing Stimulation Polymer Fracturing Fluid System Surface Tention and Interfacial Tention Reduction)

Specification of 02-Surfactant for Hydraulic Fracturing Stimulation Polymer Fracturing Fluid System Surface Tention and Interfacial Tention Reduction

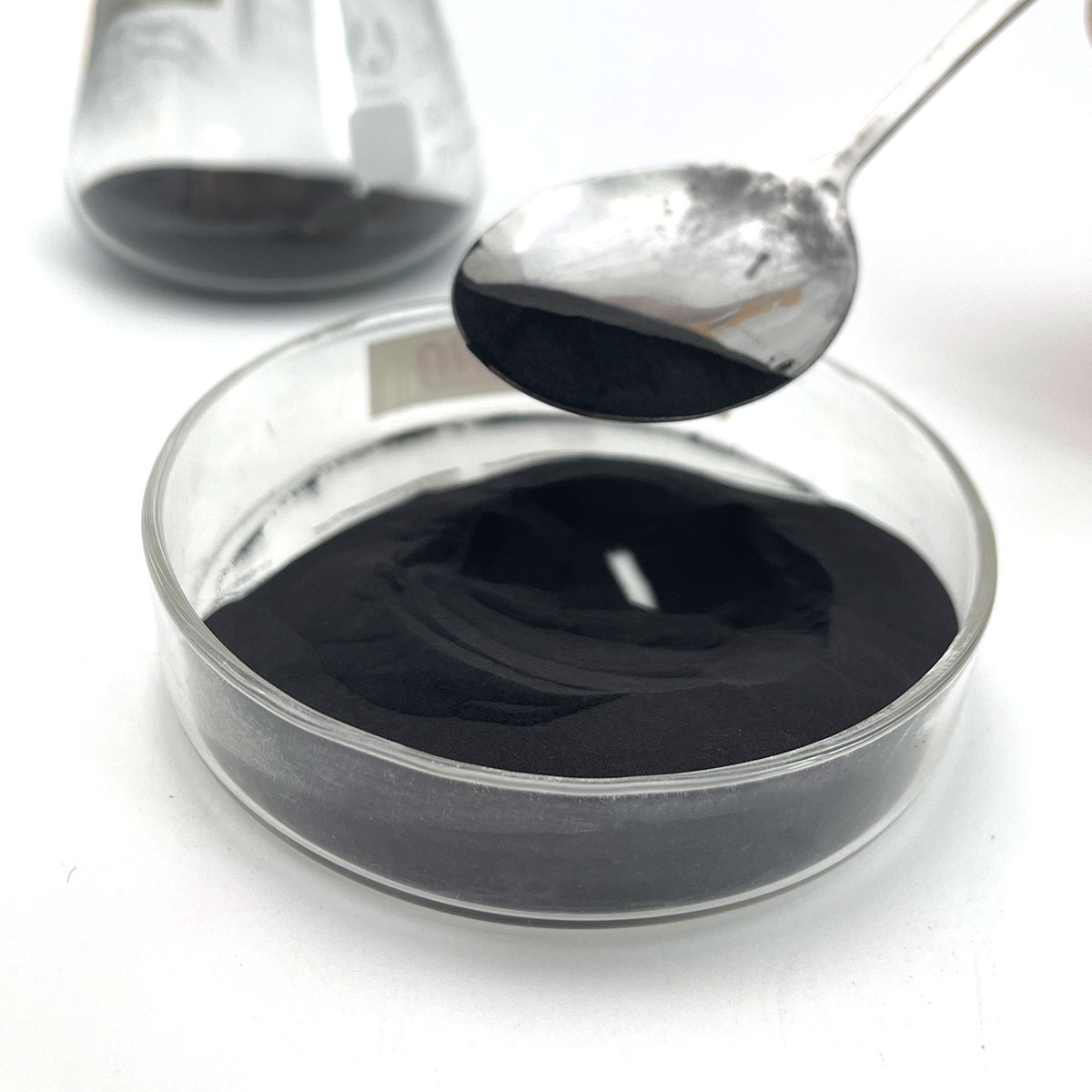

02-Surfactant is a crucial additive made for hydraulic fracturing stimulation in polymer-based fracturing fluid systems. This item concentrates on minimizing surface area tension and interfacial stress. It enhances fluid efficiency throughout fracturing procedures. The surfactant makes certain efficient liquid flow within fractures. It helps make the most of contact between the fracturing fluid and the tank rock. This process improves hydrocarbon healing.

The surfactant jobs by altering the properties of the fluid-rock user interface. It enables the liquid to spread more evenly throughout rock surfaces. This activity advertises much deeper penetration into limited formations. It protects against fluid accumulation near the wellbore. The result is much better fracture network development. The item remains efficient under high-pressure and high-temperature downhole problems. It preserves stability when blended with other fracturing fluid additives.

Secret attributes consist of solid surface stress decrease capabilities. It decreases interfacial stress in between the fracturing liquid and storage tank liquids. This avoids solution obstructions. It lowers the threat of water blockage in gas wells. The surfactant is compatible with common gelling agents and crosslinkers. It does not conflict with liquid viscosity. The product minimizes fluid loss throughout shot. It supports longer fracture lengths.

Normal dosage varieties from 0.1% to 0.5% by volume. Changes rely on tank problems and fluid composition. The surfactant executes well in brines and fresh water. It operates efficiently in temperatures as much as 300 ° F. It stays stable in pH atmospheres between 4 and 10. The formulation is non-ionic. This decreases interactions with storage tank minerals.

Safety and security is prioritized during handling. The product meets sector requirements for ecological and functional safety. It is non-corrosive to equipment. Proper storage space ensures lasting stability. The surfactant is eco-friendly. It leaves very little deposit in the development.

Applications consist of hydraulic fracturing in unusual oil and gas storage tanks. It is utilized in water-based and hybrid fracturing liquids. The item addresses challenges in low-permeability formations. It boosts post-fracturing liquid healing. Functional downtime lowers because of lowered clean-up needs.

(02-Surfactant for Hydraulic Fracturing Stimulation Polymer Fracturing Fluid System Surface Tention and Interfacial Tention Reduction)

Applications of 02-Surfactant for Hydraulic Fracturing Stimulation Polymer Fracturing Fluid System Surface Tention and Interfacial Tention Reduction

O2-Surfactant is an essential additive made use of in hydraulic fracturing to improve the efficiency of polymer-based fracturing fluids. It functions by reducing surface tension and interfacial tension within the fluid system. This activity aids the fluid spread much more equally through rock developments. Hydraulic fracturing relies on injecting high-pressure fluid right into wells to create fractures. These fractures allow oil and gas to flow even more openly. Minimizing surface area stress makes sure the liquid passes through little splits more effectively. Lower interfacial stress decreases resistance in between the fracturing fluid and hydrocarbons in the storage tank. This brings about better healing of oil and gas throughout manufacturing.

The surfactant’s capability to cut surface area tension protects against water blockage in the reservoir. Water blockage happens when water-based liquids catch hydrocarbons in rock pores. O2-Surfactant decreases this danger. It guarantees liquids drain effectively after fracturing. This boosts well productivity. The item is compatible with typical polymer systems like guar gum or artificial polymers. It preserves liquid viscosity while boosting flowback. Thickness is essential for carrying proppants into cracks. Proppants hold fractures open after stress is launched.

O2-Surfactant additionally supports liquid mixes. It protects against splitting up of oil, water, or gas phases during pumping. Stable liquids carry out consistently under high pressure and temperature. This minimizes devices wear and functional downtime. The surfactant’s chemical structure permits it to operate in both fresh and salty water. This adaptability matches differed well conditions. It executes well in low-permeability storage tanks where typical surfactants battle.

Operators take advantage of reduced chemical usage. Reduced surfactant focus attain the very same results. This reduces expenses and streamlines logistics. The product’s environmental profile fulfills market criteria. It is non-toxic and eco-friendly. This lessens eco-friendly influence throughout fracturing operations. Area tests show quicker cleanup after fracturing. Less residue continues to be in cracks. This boosts long-term well performance.

The surfactant’s function in lowering interfacial tension boosts solution control. Unsteady solutions can obstruct pipelines or storage tanks. O2-Surfactant protects against these issues. It makes certain smooth post-fracturing fluid monitoring. Its application reaches unique storage tanks like shale or limited gas formations. These sources require high-efficiency liquid systems. The product fulfills these needs without endangering security or price.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of 02-Surfactant for Hydraulic Fracturing Stimulation Polymer Fracturing Fluid System Surface Tention and Interfacial Tention Reduction

What does 02-Surfactant do in hydraulic fracturing fluid systems?

02-Surfactant cuts surface tension and interfacial tension in polymer-based fracturing fluids. This helps the fluid spread evenly through rock fractures. It stops water blocks and improves fluid recovery after the job.

How does 02-Surfactant lower surface tension?

The surfactant molecules gather at liquid-gas or liquid-liquid interfaces. This weakens the forces holding the liquid surface together. Lower surface tension lets the fluid penetrate tiny fractures more effectively.

Why is reducing interfacial tension important?

High interfacial tension between fracturing fluid and reservoir fluids creates resistance. This traps the fluid in the rock. Lowering it helps mix oil, gas, and water smoothly. It prevents pore blockages and boosts production rates.

What makes 02-Surfactant better than other surfactants?

It works well with thick polymer fluids without losing viscosity. It stays stable under high heat and pressure downhole. It resizes micelles automatically to match changing salinity and temperature.

Is 02-Surfactant safe for the environment?

It breaks down naturally after use. It meets industry standards for non-toxic additives. Testing shows minimal impact on soil or water systems. Operators handle it safely with standard protective gear.

(02-Surfactant for Hydraulic Fracturing Stimulation Polymer Fracturing Fluid System Surface Tention and Interfacial Tention Reduction)