Overview of 01-Surfactant for Hydraulic Fracturing Stimulation Polymer Fracturing Fluid System Surface Tention and Interfacial Tention Reduction

Polymer surfactants, also known as polymeric surfactants or amphiphilic polymers, are high-molecular-weight compounds that combine the properties of traditional low-molecular-weight surfactants with the unique features of polymers. Unlike small molecule surfactants, polymer surfactants offer enhanced stability, improved solubility, and the ability to form more complex structures such as micelles, hydrogels, and vesicles. These macromolecules find applications across a wide range of industries due to their tailored structures and tunable properties, which allow for precise control over interfacial behavior and solution rheology.

Features of 01-Surfactant for Hydraulic Fracturing Stimulation Polymer Fracturing Fluid System Surface Tention and Interfacial Tention Reduction

-

Molecular Weight and Structure: With a much higher molecular weight, polymer surfactants offer enhanced stability in harsh conditions and over prolonged periods compared to small molecule surfactants.

-

Tunability: The structure of polymer surfactants can be precisely engineered to include different functional groups, monomer sequences, and architectures, allowing for specific interactions and properties.

-

Multifunctionality: Apart from surface activity, they can also provide additional functionalities like thickening, rheology modification, and controlled release capabilities.

-

Self-Assembly: Capable of forming sophisticated self-assembled structures like micelles, hydrogels, and vesicles, which can encapsulate or release active ingredients in a controlled manner.

-

Environmental Compatibility: Many polymer surfactants are designed to be biodegradable and less toxic, making them suitable for eco-friendly applications.

-

Temperature and pH Responsiveness: Some polymer surfactants exhibit responsive behavior to changes in temperature or pH, enabling stimuli-responsive systems.

(01-Surfactant for Hydraulic Fracturing Stimulation Polymer Fracturing Fluid System Surface Tention and Interfacial Tention Reduction)

Specification of 01-Surfactant for Hydraulic Fracturing Stimulation Polymer Fracturing Fluid System Surface Tention and Interfacial Tention Reduction

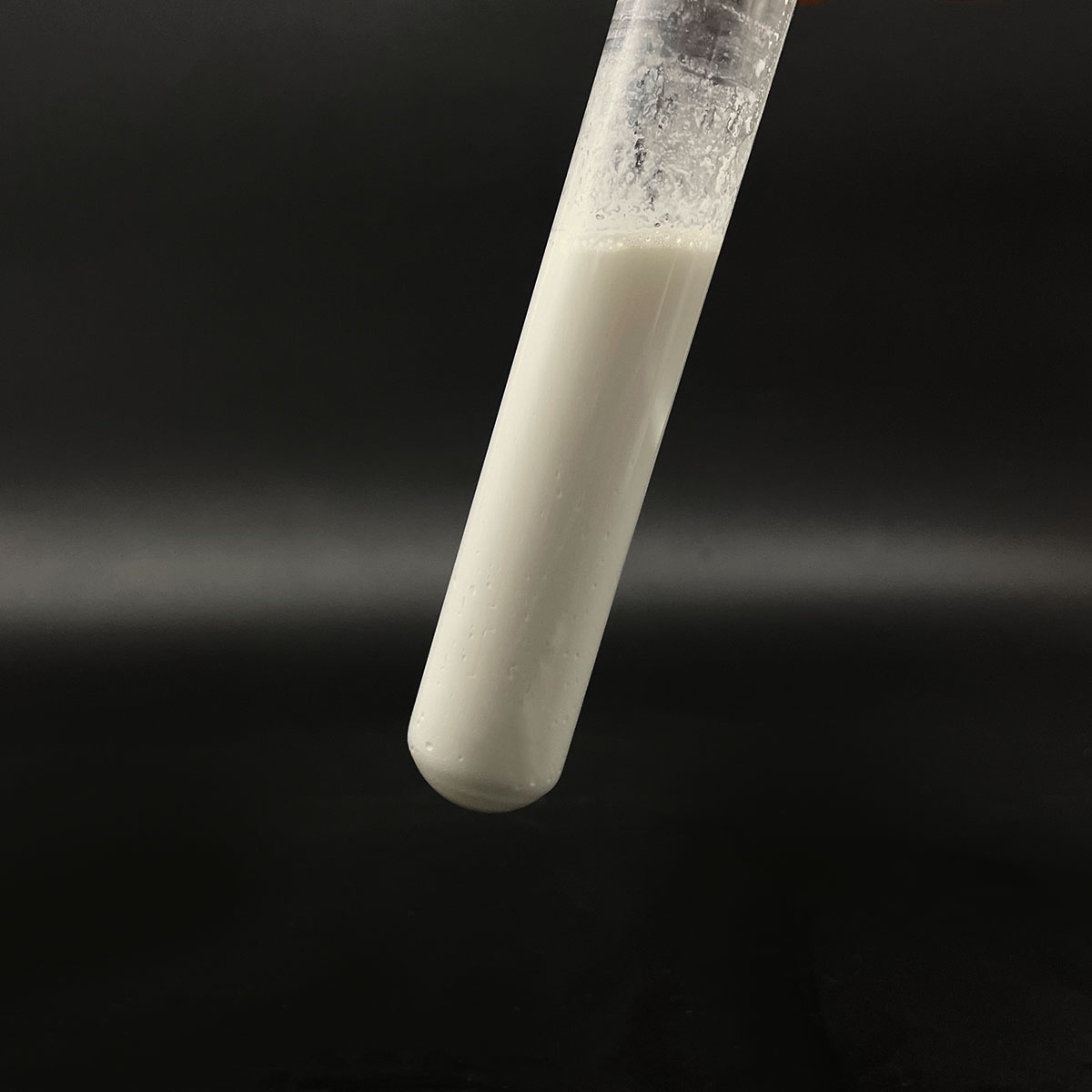

01-Surfactant is a vital additive for hydraulic fracturing excitement in polymer fracturing liquid systems. It works to lower surface stress and interfacial tension. This enhances fluid efficiency throughout oil and gas recuperation. The item ensures far better fluid spread in rock developments. It additionally aids release caught hydrocarbons a lot more efficiently.

The surfactant is a non-ionic mix created for high-temperature and high-pressure conditions. Its main elements consist of ethoxylated alcohols and specialized co-surfactants. These active ingredients interact to weaken the pressures in between liquids and solids. The common concentration in fracturing fluid arrays from 0.1% to 0.5% by weight. This depends on storage tank problems and liquid layout.

Surface stress decrease is critical for liquid infiltration right into limited rock pores. The product decreases surface tension from 72 mN/m to around 30 mN/m in water-based systems. This allows fracturing fluid to go into smaller sized fractures. Interfacial tension between oil and water phases is also reduced. Values go down from 30 mN/m to below 5 mN/m. This makes oil variation much easier throughout flowback.

The surfactant stays secure in fluids with salinity up to 200,000 ppm. It does well in temperatures as much as 300 ° F. Compatibility with common additives like gelling representatives and biocides is confirmed. No precipitation or phase separation takes place under regular use.

pH stability varies from 4 to 10. This matches most fracturing fluid formulations. The product is offered as a clear liquid with low thickness. It blends quickly without additional tools. Storage space referrals consist of maintaining containers secured in cool, dry areas. Service life is one year from manufacturing.

Environmental and safety factors fulfill market criteria. The product is biodegradable under cardiovascular problems. It has reduced poisoning for marine life. Handling needs fundamental PPE like handwear covers and goggles. Spills should be consisted of with absorptive products.

Dosage changes depend upon downhole temperature level and water solidity. Field tests reveal optimal outcomes when added throughout the pre-mix stage. The surfactant does not affect fluid thickness or proppant transport. Operational performance rises due to minimized pump stress and fluid loss.

(01-Surfactant for Hydraulic Fracturing Stimulation Polymer Fracturing Fluid System Surface Tention and Interfacial Tention Reduction)

Applications of 01-Surfactant for Hydraulic Fracturing Stimulation Polymer Fracturing Fluid System Surface Tention and Interfacial Tention Reduction

01-Surfactant plays a crucial duty in hydraulic fracturing stimulation for oil and gas extraction. It is made to decrease surface stress and interfacial tension in polymer-based fracturing liquids. Hydraulic fracturing depends on injecting high-pressure fluid right into shale formations to produce cracks. This releases caught hydrocarbons. The fluid’s efficiency relies on its capability to combine with oil and gas while receding successfully. High surface stress in the fluid can restrict its penetration into rock pores. High interfacial stress between the fluid and hydrocarbons can catch sources in the reservoir.

01-Surfactant addresses these obstacles. It decreases surface area tension in the fracturing liquid. This enables the liquid to spread even more evenly with fractures. It additionally reduces interfacial stress between the liquid and hydrocarbons. This protects against oil and gas beads from staying with shake surface areas. The result is enhanced liquid recovery and greater hydrocarbon production.

The surfactant incorporates with polymer fracturing fluid systems without influencing their viscosity or security. Polymers provide the required density to lug proppants into cracks. 01-Surfactant makes sure the liquid preserves this function while boosting its ability to communicate with hydrocarbons. This combination protects against obstructions in the fracture network. It guarantees regular flowback of the fluid after fracturing.

Field examinations reveal 01-Surfactant rises well efficiency by up to 20% contrasted to standard liquids. It minimizes deposit left in storage tanks. This minimizes damages to the development in time. Operators require fewer chemical additives to achieve target efficiency. This decreases costs and environmental impact.

The product works across varying temperatures and salinity levels. It remains reliable in harsh tank conditions. Compatibility with other fracturing chemicals ensures smooth integration into existing process.

01-Surfactant sustains sustainable extraction techniques. It reduces water and energy usage by boosting fluid performance. Less repeat therapies are required to preserve production rates. This prolongs the functional life of wells.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of 01-Surfactant for Hydraulic Fracturing Stimulation Polymer Fracturing Fluid System Surface Tention and Interfacial Tention Reduction

What does the surfactant do in hydraulic fracturing fluid systems?

Surfactants lower surface tension and interfacial tension in the fluid. This helps the fluid spread evenly through rock fractures. It improves contact between the fluid and the rock surface. Better contact allows more efficient oil or gas recovery.

How does the surfactant reduce surface tension?

Surfactant molecules collect at the boundary between liquids or between liquid and solid. They weaken the forces holding liquid molecules together. This makes the liquid spread easier. Lower surface tension helps the fluid penetrate tiny fractures.

Why is reducing interfacial tension important?

Lower interfacial tension lets the fracturing fluid mix better with underground hydrocarbons. This stops oil or gas from forming separate droplets. It ensures smoother flow back to the well. Improved mixing boosts overall stimulation effectiveness.

Does the surfactant affect fluid stability?

The surfactant works without harming fluid stability. It balances tension reduction with maintaining viscosity. This keeps the fluid strong enough to carry proppants. Proppants hold fractures open after pumping stops.

Is the surfactant safe for the environment?

The surfactant is designed to meet environmental standards. It breaks down naturally over time. Safe handling practices minimize risks during storage and use. Always check local regulations before application.

(01-Surfactant for Hydraulic Fracturing Stimulation Polymer Fracturing Fluid System Surface Tention and Interfacial Tention Reduction)