Overview of Silicone Surfactant for Flexible/Rigid PU Foam

Polymer surfactants, also known as polymeric surfactants or amphiphilic polymers, are high-molecular-weight compounds that combine the properties of traditional low-molecular-weight surfactants with the unique features of polymers. Unlike small molecule surfactants, polymer surfactants offer enhanced stability, improved solubility, and the ability to form more complex structures such as micelles, hydrogels, and vesicles. These macromolecules find applications across a wide range of industries due to their tailored structures and tunable properties, which allow for precise control over interfacial behavior and solution rheology.

Features of Silicone Surfactant for Flexible/Rigid PU Foam

-

Molecular Weight and Structure: With a much higher molecular weight, polymer surfactants offer enhanced stability in harsh conditions and over prolonged periods compared to small molecule surfactants.

-

Tunability: The structure of polymer surfactants can be precisely engineered to include different functional groups, monomer sequences, and architectures, allowing for specific interactions and properties.

-

Multifunctionality: Apart from surface activity, they can also provide additional functionalities like thickening, rheology modification, and controlled release capabilities.

-

Self-Assembly: Capable of forming sophisticated self-assembled structures like micelles, hydrogels, and vesicles, which can encapsulate or release active ingredients in a controlled manner.

-

Environmental Compatibility: Many polymer surfactants are designed to be biodegradable and less toxic, making them suitable for eco-friendly applications.

-

Temperature and pH Responsiveness: Some polymer surfactants exhibit responsive behavior to changes in temperature or pH, enabling stimuli-responsive systems.

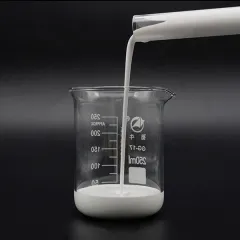

(Silicone Surfactant for Flexible/Rigid PU Foam)

Specification of Silicone Surfactant for Flexible/Rigid PU Foam

Silicone surfactants are vital components for making polyurethane foam. They manage the foam development procedure. They control bubble shapes and size. They stabilize the foam framework as it increases and sets. This avoids collapse or unequal openings. Excellent foam requires this control.

Versatile PU foam calls for surfactants that produce primarily open cells. Open up cells let air action freely through the foam. This makes soft, squishy foam for furnishings pillows, mattresses, and car seats. The surfactant aids the fluid chemicals mix well. It makes sure bubbles form equally. It keeps the foam secure until it solidifies correctly. Versatile foam surfactants often require great compatibility with certain foam dishes.

Inflexible PU foam needs surfactants that produce mostly closed cells. Closed cells trap gas inside. This makes foam tight and provides exceptional insulation. Rigid foam is utilized in building insulation, fridges, and colders. The surfactant needs to help form extremely little, uniform shut cells. This takes full advantage of insulation power. It must likewise give strong bubble wall surfaces. This protects against cells damaging as the foam broadens quickly. Stiff foam surfactants commonly need greater stability under processing conditions.

Employees add these surfactants to the polyol blend prior to blending with isocyanate. The best surfactant type and quantity are vital. The selection depends on the foam kind. It depends upon the preferred cell framework. It depends on the specific foam system chemicals. The surfactant straight influences foam high quality. It impacts thickness, comfort, assistance, and insulation worth. Selecting the appropriate silicone surfactant makes certain the foam carries out well in its final usage.

(Silicone Surfactant for Flexible/Rigid PU Foam)

Applications of Silicone Surfactant for Flexible/Rigid PU Foam

Silicone surfactants are vital for making both flexible and inflexible polyurethane foams. They manage the surface area tension of the fluid combinations during the lathering response. This is critical. It assists create the foam framework appropriately.

In adaptable PU foam, like for cushions or child seat, silicone surfactants do several important tasks. They help blend the liquid components equally. They support the bubbles as they develop and expand. They make the bubbles smaller and much more uniform. This produces foam with consistent gentleness, convenience, and resilience. The foam really feels better and lasts much longer. Without the surfactant, the foam could collapse or create big holes. It would not carry out well.

Rigid PU foam requires various properties. This foam is utilized for insulation in appliances or buildings. Silicone surfactants here make the foam cells extremely great and closed. Fine, shut cells catch the blowing gas effectively. This makes best use of the insulation power. The surfactants likewise make sure the liquid mixture streams well into mold and mildews or tooth cavities before it solidifies. They help the foam surge evenly without splitting or shrinking. This gives strong, dimensionally stable insulation panels. Excellent circulation means much less waste and consistent item high quality.

Makers use silicone surfactants for reputable foam production. The surfactants protect against troubles like foam collapse or coarse cell framework. They make the procedure simpler to regulate. Different foam kinds require certain surfactant chemistries. Experts choose surfactants based upon the foam’s needed density, solidity, and cell framework. The ideal surfactant makes a huge difference in foam efficiency and look. Silicone surfactants are key ingredients across the entire PU foam market.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Silicone Surfactant for Flexible/Rigid PU Foam

Silicone surfactants are key for flexible and rigid polyurethane foam production. Here are five common questions about them.

What exactly does a silicone surfactant do in PU foam?

It controls foam formation. The surfactant manages bubble size and structure. This prevents collapse or uneven cells. It ensures the foam rises evenly and sets correctly.

Why is a silicone surfactant necessary for flexible foam?

Flexible foam needs open cells for softness and breathability. The surfactant helps create these cells. Without it, the foam might be too dense or have closed cells. Then comfort and performance suffer.

Why is a silicone surfactant used in rigid foam too?

Rigid foam requires strength and insulation. The surfactant stabilizes the mix during expansion. It ensures small, uniform cells. This boosts insulation and structural integrity.

How does silicone surfactant impact foam quality?

It directly affects cell structure and density. Proper use gives consistent texture and performance. Too little causes voids or splits. Too much leads to shrinkage or weak foam.

How much silicone surfactant is needed per batch?

Dosage varies by foam type and other chemicals. Typically it’s 0.5% to 2.5% of the total mix. Always test small batches first. Adjust based on foam density and cell structure needs.

(Silicone Surfactant for Flexible/Rigid PU Foam)