Overview of Factory Supply Surfactant for Oilfield

Polymer surfactants, also known as polymeric surfactants or amphiphilic polymers, are high-molecular-weight compounds that combine the properties of traditional low-molecular-weight surfactants with the unique features of polymers. Unlike small molecule surfactants, polymer surfactants offer enhanced stability, improved solubility, and the ability to form more complex structures such as micelles, hydrogels, and vesicles. These macromolecules find applications across a wide range of industries due to their tailored structures and tunable properties, which allow for precise control over interfacial behavior and solution rheology.

Features of Factory Supply Surfactant for Oilfield

-

Molecular Weight and Structure: With a much higher molecular weight, polymer surfactants offer enhanced stability in harsh conditions and over prolonged periods compared to small molecule surfactants.

-

Tunability: The structure of polymer surfactants can be precisely engineered to include different functional groups, monomer sequences, and architectures, allowing for specific interactions and properties.

-

Multifunctionality: Apart from surface activity, they can also provide additional functionalities like thickening, rheology modification, and controlled release capabilities.

-

Self-Assembly: Capable of forming sophisticated self-assembled structures like micelles, hydrogels, and vesicles, which can encapsulate or release active ingredients in a controlled manner.

-

Environmental Compatibility: Many polymer surfactants are designed to be biodegradable and less toxic, making them suitable for eco-friendly applications.

-

Temperature and pH Responsiveness: Some polymer surfactants exhibit responsive behavior to changes in temperature or pH, enabling stimuli-responsive systems.

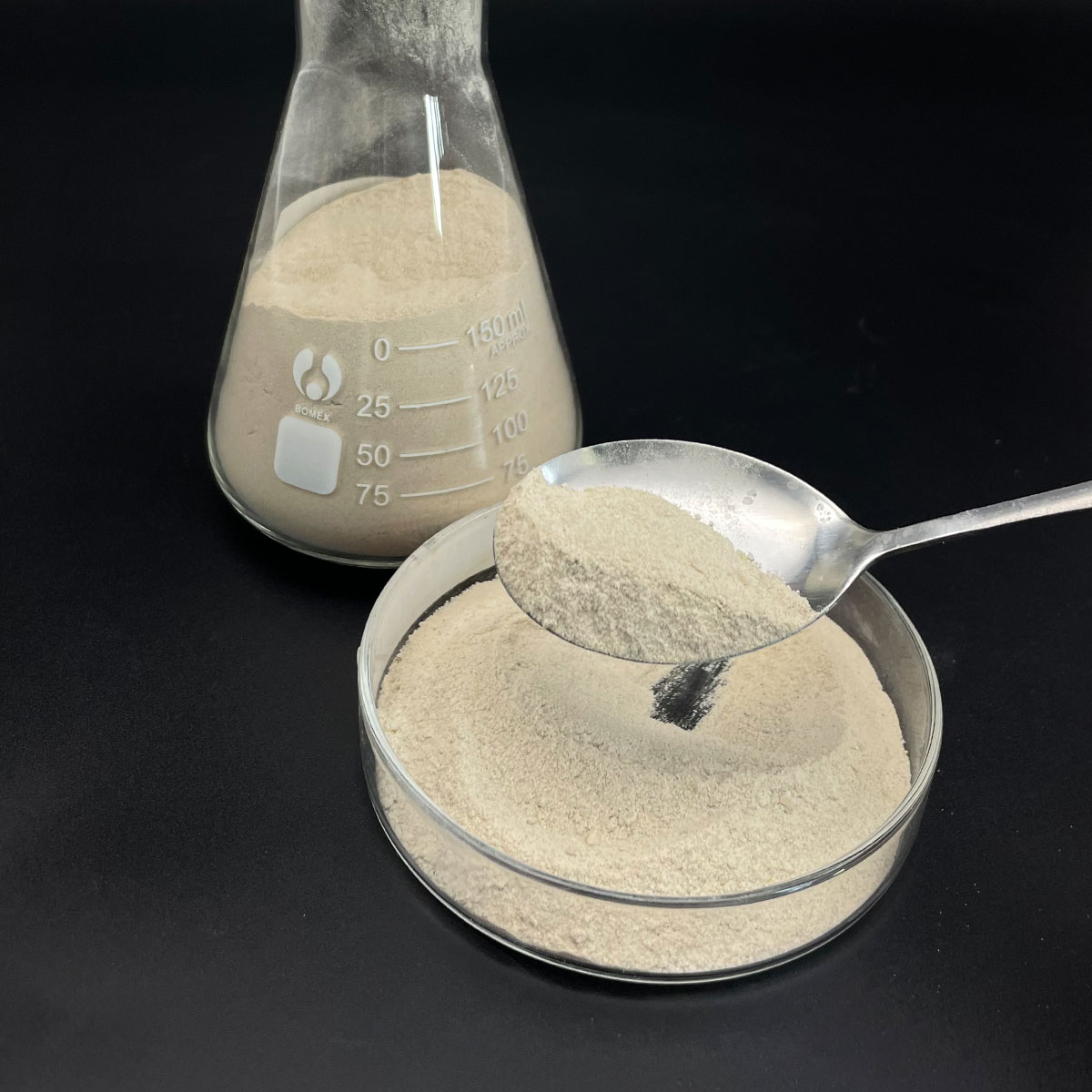

(Factory Supply Surfactant for Oilfield)

Specification of Factory Supply Surfactant for Oilfield

Our factory produces surfactants specifically for oilfield operations. These chemicals help improve oil recovery. We offer several types. Anionic surfactants work well in high-temperature reservoirs. Nonionic surfactants resist hard water conditions. Cationic surfactants bond effectively with rock surfaces. Amphoteric surfactants adjust based on the environment.

Each surfactant contains carefully selected active agents. These agents reduce surface tension between oil and water. They also lower interfacial tension at oil-rock interfaces. The composition includes stabilizers for harsh downhole conditions. We avoid volatile organic compounds. Our products meet strict environmental standards.

Injection is the primary application method. Workers mix surfactants with water or brine. This solution gets pumped into injection wells. The mixture spreads through rock pores. It releases trapped oil droplets. Surfactants prevent emulsion blockages in pipelines. They minimize scale formation on equipment.

Key benefits include increased oil production rates. Surfactants enhance water flooding efficiency. They reduce operational costs by cutting chemical usage. Our products extend equipment lifespan through corrosion inhibition. They maintain stability in saltwater or acidic formations.

Customization options are available. We adjust viscosity for different permeability levels. Concentration varies based on reservoir temperature. Our technical team provides formulation support. They analyze field data to optimize product performance. Batch testing ensures consistent quality before shipment. Packaging comes in drums or bulk containers for easy handling. Safety data sheets accompany every order.

(Factory Supply Surfactant for Oilfield)

Applications of Factory Supply Surfactant for Oilfield

Factory supply surfactants help oilfield operations run smoother. These chemicals act like soap for oil reservoirs. They reduce surface tension where oil and water meet. This makes trapped oil droplets flow easier through rock pores. Drilling teams add surfactants to mud systems. This prevents clay swelling. Clay swelling can stick pipes or damage formations. Fracturing fluids use surfactants too. They help water-based fluids carry sand deeper into cracks. After fracturing, surfactants help well cleanup. They stop water blocks from forming near the wellbore. Water blocks slow oil production.

Production chemicals often contain surfactants. They tackle emulsion problems. Crude oil and water can mix into stubborn emulsions. Surfactants break these emulsions fast. This gives cleaner oil and less water handling. Scale inhibitors work better with surfactants. Surfactants stop scale crystals from sticking to pipes. This keeps flow paths open longer. Surfactants also aid in enhanced oil recovery. Engineers inject them with steam or water. They help push leftover oil towards production wells. This squeezes more oil from old fields.

Field operators see direct benefits. Surfactants boost oil output. They cut downtime from flow issues. They reduce chemical use overall. These chemicals protect equipment from damage. They extend equipment life. Surfactants handle tough downhole conditions. They work in high heat and salty water. Factory supply ensures steady availability. It supports urgent field needs. Quality control matters for consistent results.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Factory Supply Surfactant for Oilfield

Surfactants for oilfields are chemicals. They help in oil recovery. These chemicals reduce surface tension. That makes oil flow easier.

What is a surfactant for oilfield use?

It is a special chemical. It changes how liquids interact. Oil sticks to rock surfaces underground. Surfactants loosen that oil. They help push oil toward wells.

Why use surfactants in oilfields?

They boost oil production. Old wells still have oil. This oil is trapped. Surfactants release trapped oil. They make water and oil mix better. This improves oil recovery rates.

How do surfactants work in oil recovery?

They act like detergents. Imagine oil clinging to rock. Surfactants break oil’s grip. They let water sweep oil away. Then oil moves to production wells.

What types of surfactants are available?

Common types are anionic and nonionic. Anionic ones work in salty conditions. Nonionic ones handle high temperatures. Both types reduce oil-water tension.

How to choose the right surfactant for an oilfield project?

Consider the reservoir first. Check temperature and salt levels. Test different surfactants in labs. Match the chemical to well conditions. Get samples before large orders.

(Factory Supply Surfactant for Oilfield)