Overview of Silicone Surfactant Jc-7700 for Polyurethane Rigid Foam PU Foam Silicone Oil

Polymer surfactants, also known as polymeric surfactants or amphiphilic polymers, are high-molecular-weight compounds that combine the properties of traditional low-molecular-weight surfactants with the unique features of polymers. Unlike small molecule surfactants, polymer surfactants offer enhanced stability, improved solubility, and the ability to form more complex structures such as micelles, hydrogels, and vesicles. These macromolecules find applications across a wide range of industries due to their tailored structures and tunable properties, which allow for precise control over interfacial behavior and solution rheology.

Features of Silicone Surfactant Jc-7700 for Polyurethane Rigid Foam PU Foam Silicone Oil

-

Molecular Weight and Structure: With a much higher molecular weight, polymer surfactants offer enhanced stability in harsh conditions and over prolonged periods compared to small molecule surfactants.

-

Tunability: The structure of polymer surfactants can be precisely engineered to include different functional groups, monomer sequences, and architectures, allowing for specific interactions and properties.

-

Multifunctionality: Apart from surface activity, they can also provide additional functionalities like thickening, rheology modification, and controlled release capabilities.

-

Self-Assembly: Capable of forming sophisticated self-assembled structures like micelles, hydrogels, and vesicles, which can encapsulate or release active ingredients in a controlled manner.

-

Environmental Compatibility: Many polymer surfactants are designed to be biodegradable and less toxic, making them suitable for eco-friendly applications.

-

Temperature and pH Responsiveness: Some polymer surfactants exhibit responsive behavior to changes in temperature or pH, enabling stimuli-responsive systems.

(Silicone Surfactant Jc-7700 for Polyurethane Rigid Foam PU Foam Silicone Oil)

Specification of Silicone Surfactant Jc-7700 for Polyurethane Rigid Foam PU Foam Silicone Oil

Jc-7700 silicone surfactant is a key additive for making rigid polyurethane foam. This product helps control foam cell structure during production. It ensures the foam forms uniform small cells. That makes the final material strong and stable. Jc-7700 works well with common polyol systems. It mixes easily into foam formulations. You get consistent results batch after batch.

The surfactant improves foam flow inside molds. That allows complete filling of complex shapes. It reduces the chance of voids or defects. The foam cures evenly with good surface quality. Jc-7700 also boosts thermal insulation properties. Foam made with it keeps heat transfer low. This matters for energy-saving applications like building insulation.

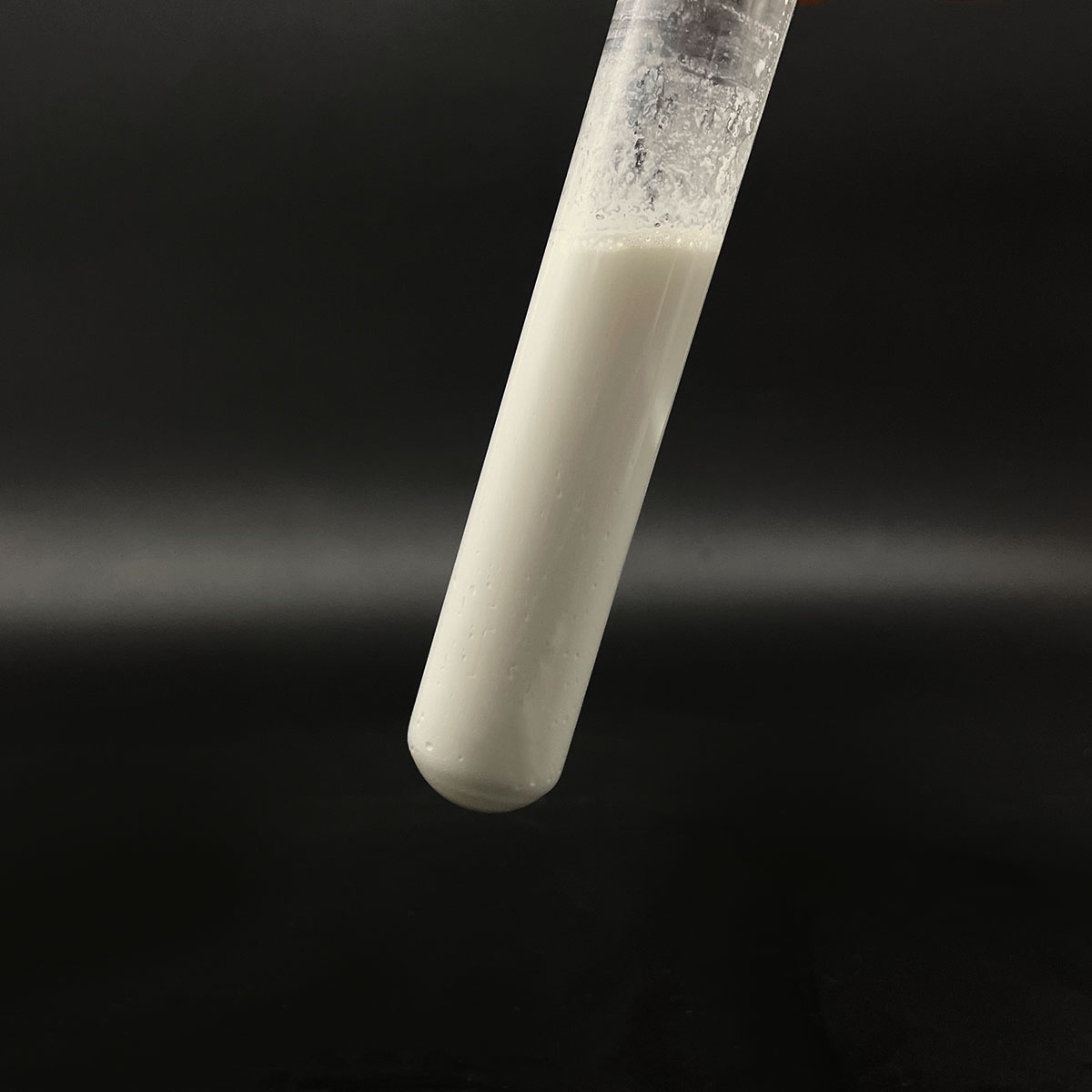

Jc-7700 looks like a clear pale yellow liquid. Its viscosity stays low for easy pumping and handling. The density is about 1.04 g/cm³ at room temperature. The flash point is above 150°C for safe storage. Use between 1.0 to 3.0 parts per hundred parts of polyol. Adjust based on your specific foam system needs.

Store Jc-7700 in original sealed containers. Keep away from moisture and extreme heat. Ideal storage temperature is 5°C to 35°C. Use within twelve months for best performance. Always wear gloves and eye protection when handling. Ensure good ventilation in work areas. This surfactant helps factories produce rigid PU foam efficiently. It lowers waste and improves product consistency.

(Silicone Surfactant Jc-7700 for Polyurethane Rigid Foam PU Foam Silicone Oil)

Applications of Silicone Surfactant Jc-7700 for Polyurethane Rigid Foam PU Foam Silicone Oil

JC-7700 silicone surfactant is made for rigid polyurethane foam. It helps control the foam while it forms. This is very important for getting good foam. The foam needs a stable structure. JC-7700 makes this happen. It helps bubbles form evenly. It keeps these bubbles the right size. It stops them from breaking or joining together too much. This results in foam with a fine, even cell structure.

Good foam needs consistent cells. JC-7700 ensures this consistency. It makes the foam rise steadily. This prevents problems like collapse or shrinkage. The foam stays strong and light. It also insulates better. Uniform cells trap air effectively. This gives the foam its thermal performance.

JC-7700 works well with many rigid foam systems. It is compatible with different blowing agents. This includes water and common physical blowing agents. It works reliably in various processing conditions. This makes it useful for different factories and machines.

This surfactant is used in many rigid foam products. Appliances like refrigerators and freezers use it. The foam insulation inside needs high quality. JC-7700 helps achieve this. Construction panels for roofs and walls also use it. These panels require strong, stable foam. JC-7700 delivers the necessary performance. Pipes and tanks needing insulation benefit too. The foam must fill spaces completely. JC-7700 helps create a good seal. Other applications include packaging and industrial uses. Anywhere rigid PU foam needs reliable performance, JC-7700 is a key ingredient. It makes the foam process easier. The final product is better.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Silicone Surfactant Jc-7700 for Polyurethane Rigid Foam PU Foam Silicone Oil

What does JC-7700 silicone surfactant do?

JC-7700 stabilizes the foam during formation. It controls bubble size and structure. This creates uniform, fine cells in rigid polyurethane foam. Good cell structure improves the foam’s insulation and strength.

Why use JC-7700 in rigid PU foam?

It ensures cells are consistent throughout the foam block. Consistent cells mean better thermal insulation performance. The foam also gets better physical strength. It helps the liquid chemicals flow well into molds. This leads to complete filling and smoother surfaces.

How much JC-7700 should I add?

Typical use levels range from 1.0 to 2.5 parts per hundred parts polyol (php). The exact amount depends on your specific foam formulation. Factors include the polyol type, blowing agents used, and desired foam density. Always test to find the best level for your system.

Is JC-7700 compatible with common PU systems?

Yes. JC-7700 works well with most standard polyols used for rigid foam. It is compatible with HCFO, HFO, and hydrocarbon blowing agents. It performs effectively in both pentane-blown and water-blown rigid foam formulations.

How should I store JC-7700?

Store JC-7700 in its original containers. Keep containers tightly shut. Store in a cool, dry place away from direct sunlight. Avoid temperatures above 40°C (104°F). Protect it from moisture. Proper storage ensures consistent performance over time.

(Silicone Surfactant Jc-7700 for Polyurethane Rigid Foam PU Foam Silicone Oil)