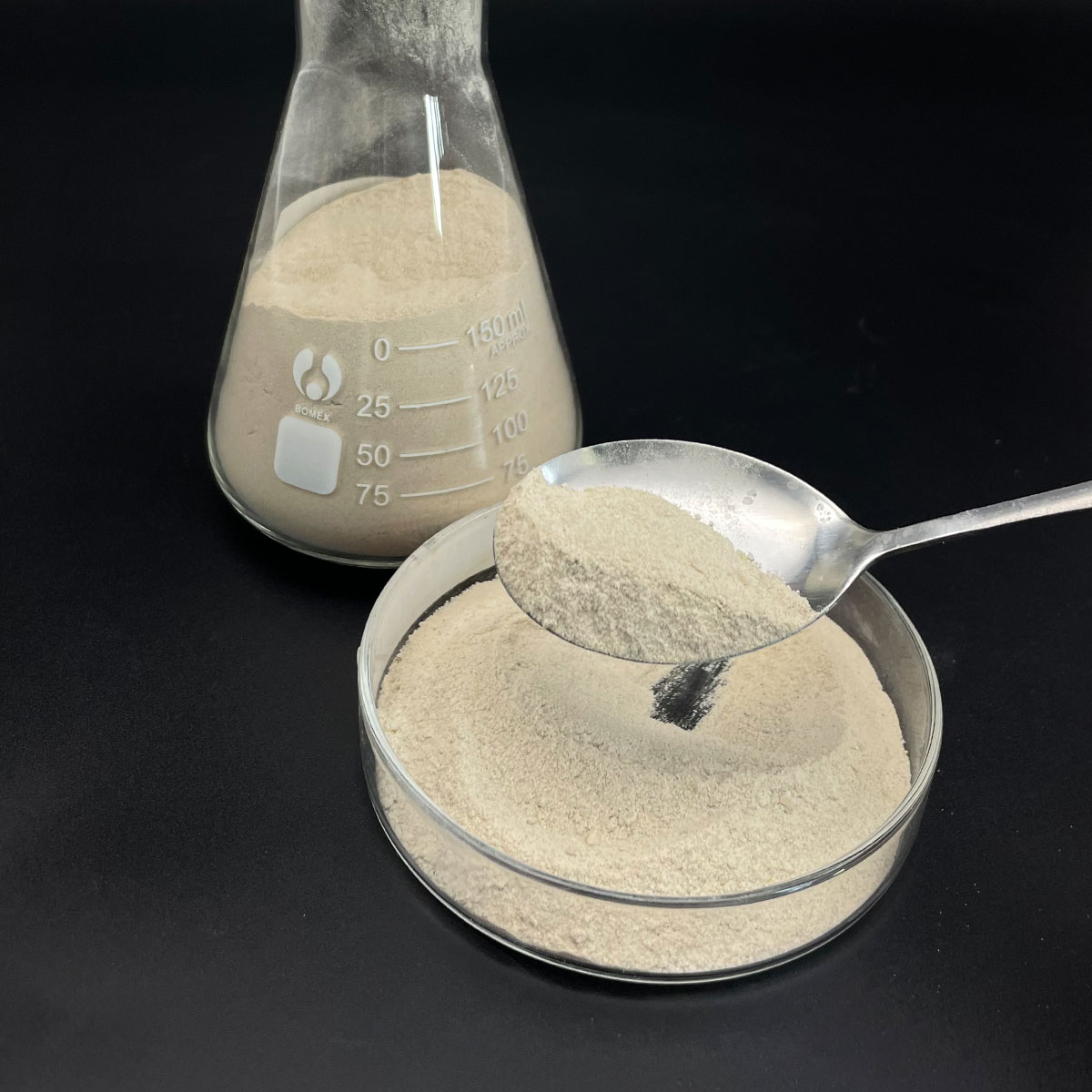

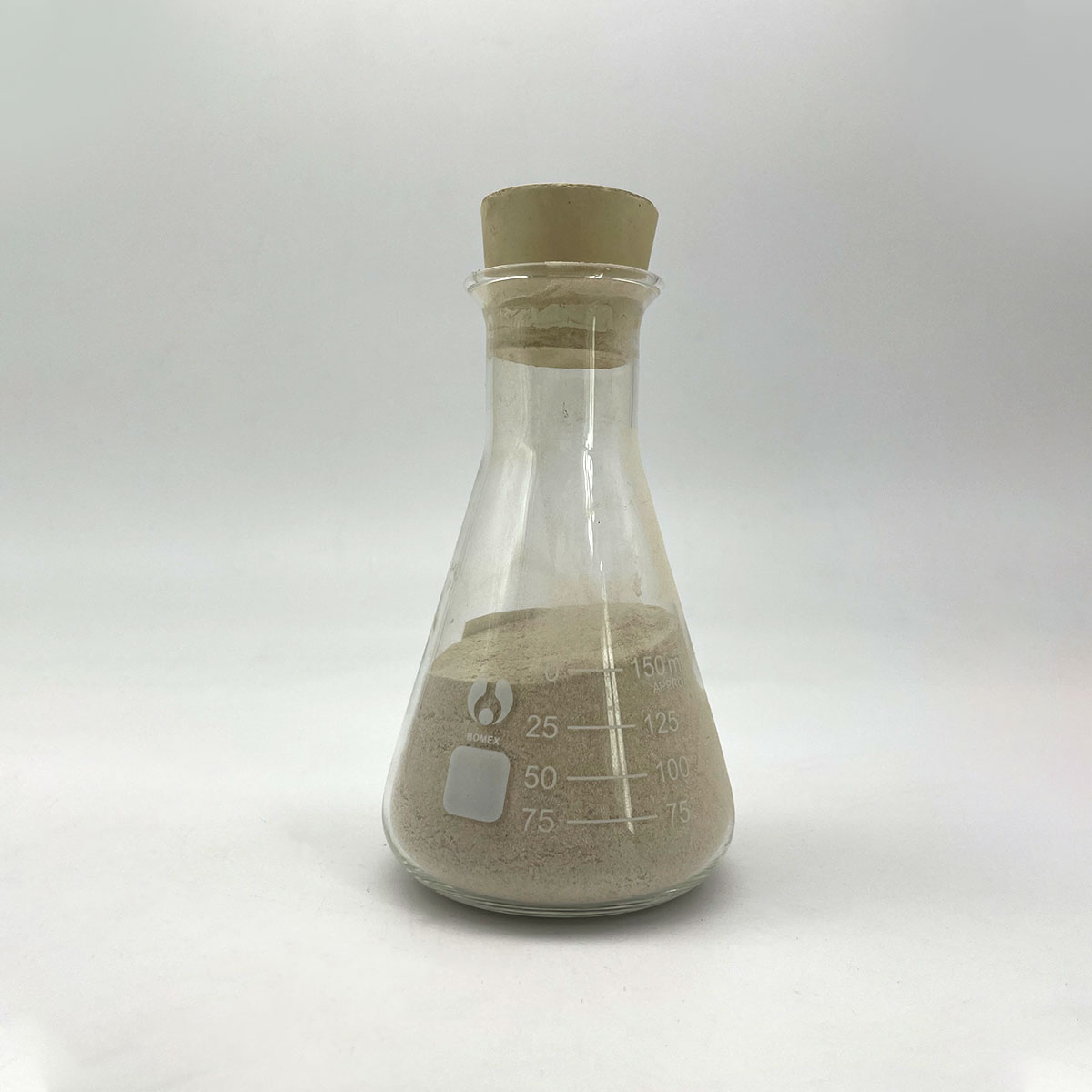

Overview of Activated Alumina Micropowder as Catalyst Carrier

Amphoteric surfactants are a unique class of surface-active agents that possess both cationic and anionic properties, depending on the pH of the system they are in. They contain both a positively charged group (like a quaternary ammonium salt) and a negatively charged group (such as a carboxylate or sulfonate), which can ionize depending on the surrounding conditions. This dual nature grants them exceptional versatility, making them effective in a wide range of pH environments and compatible with other surfactant types. They are known for their mildness and excellent dermatological compatibility, rendering them particularly suitable for personal care applications.

Features of Activated Alumina Micropowder as Catalyst Carrier

-

pH Responsiveness: Their charge varies with pH, becoming cationic in acidic conditions and anionic in alkaline, with a zwitterionic (neutral) state at the isoelectric point.

-

Mildness: Known for being gentle on skin and eyes, making them ideal for sensitive applications like baby care and personal hygiene products.

-

Foaming Properties: Can generate rich, stable foam even in hard water conditions, enhancing their use in cleaning products.

-

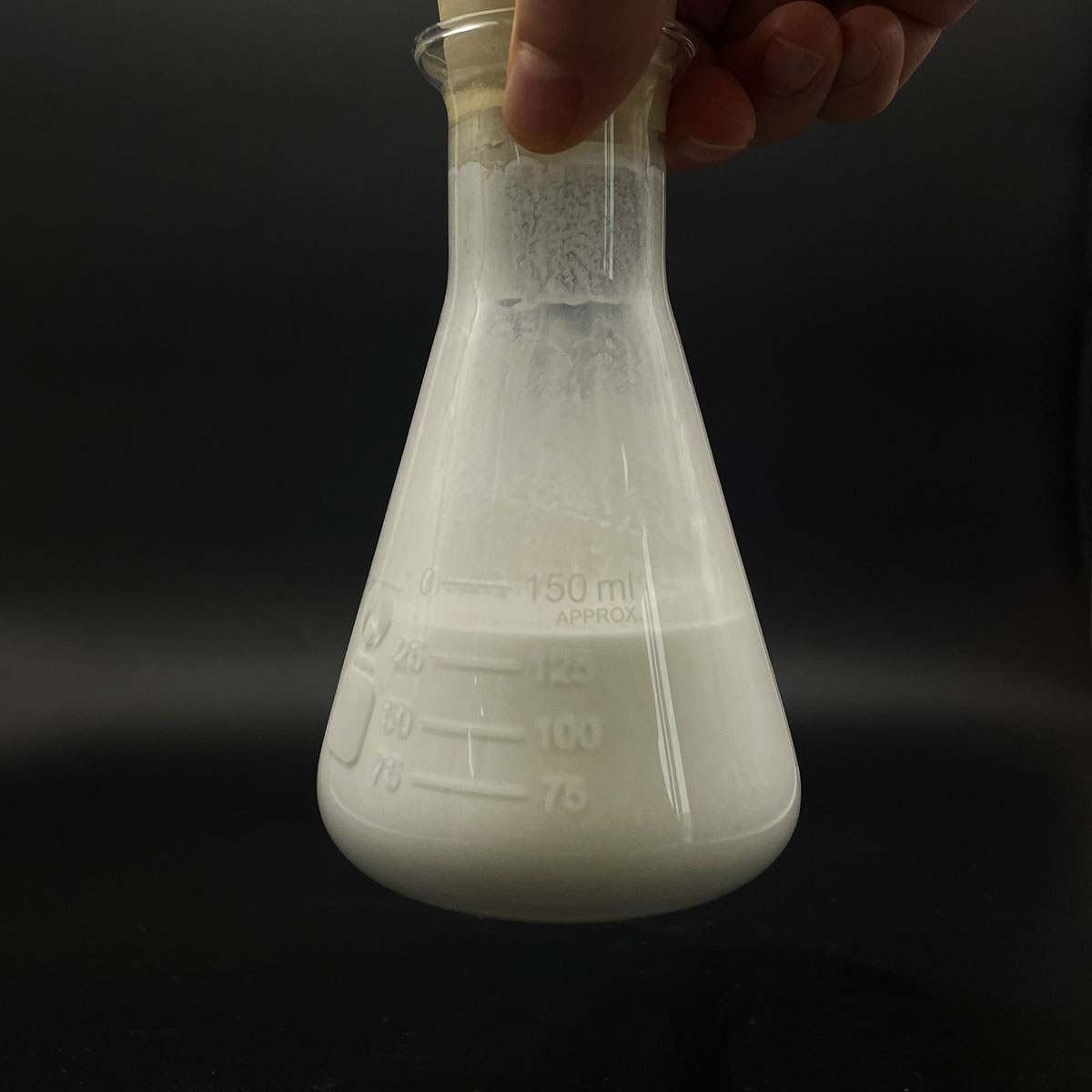

Emulsification: Efficient emulsifiers capable of forming both oil-in-water (O/W) and water-in-oil (W/O) emulsions, depending on the formulation and pH.

-

Compatibility: Because they have both anionic and cationic properties, they are compatible with other types of surfactants and can work synergistically to enhance cleaning effects.

-

Biodegradability: Many amphoteric surfactants are readily biodegradable, contributing to their environmentally friendly profile.

(Activated Alumina Micropowder as Catalyst Carrier)

Specification of Activated Alumina Micropowder as Catalyst Carrier

Turned on alumina micropowder functions as a catalyst carrier in industrial applications. It provides high area and porous framework, making it effective for supporting catalytic products. The product is chemically secure and immune to thermal shock, ensuring resilience under harsh conditions.

The material has a controlled fragment size circulation, generally between 1-50 micrometers. This uniformity boosts contact between catalysts and catalysts, boosting reaction effectiveness. Its high purity (over 99%) lessens contaminations that could disrupt catalytic procedures.

Turned on alumina micropowder includes adjustable pore dimensions, varying from 2-10 nanometers. This adaptability allows modification for specific reactions. The pores supply sufficient room for active catalytic elements to connect, improving total efficiency.

The product withstands temperature levels as much as 1000 ° C without structural destruction. This thermal security avoids sintering or collapse during high-heat procedures. It keeps mechanical toughness also under extended exposure to acidic or alkaline environments.

Moisture resistance is an additional vital quality. The product adsorbs minimal water, preventing driver deactivation brought on by moisture. This residential or commercial property is essential in gas-phase reactions where wetness control is important.

Surface level of acidity can be customized throughout manufacturing. Adjusting level of acidity degrees maximizes the service provider’s interaction with various stimulants, boosting selectivity and yield. The material’s inert nature guarantees it does not react with many chemicals, preserving catalyst honesty.

Applications include petroleum refining, petrochemical handling, and environmental catalysis. It sustains stimulants in hydrotreating, oxidation, and discharge control systems. Its flexibility makes it suitable for both fixed-bed and fluidized-bed activators.

Handling requires common industrial precaution. The powder is non-toxic but should be kept in dry conditions to keep performance. Packaging choices include moisture-resistant bags or secured containers.

Fragment morphology is engineered for ideal circulation and dispersion. Spherical or irregular forms are offered to match reactor layouts. Reduced bulk thickness reduces stress drops in catalytic beds, enhancing operational effectiveness.

Cost-effectiveness stems from lengthy service life and reusability. Spent providers can frequently be restored via calcination, restoring their initial homes. This lowers waste and functional costs with time.

Customized formulas are possible to meet certain catalytic requirements. Criteria like area, pore volume, and chemical composition can be adjusted during manufacturing. Technical support is provided to help in picking the optimum quality for each application.

(Activated Alumina Micropowder as Catalyst Carrier)

Applications of Activated Alumina Micropowder as Catalyst Carrier

Activated alumina micropowder serves as a stimulant service provider in several markets. It has a high area. This makes it optimal for holding energetic catalytic materials. The permeable framework permits also circulation of drivers. This enhances response effectiveness. It deals with heats well. This security maintains stimulants working much longer in extreme conditions.

In the petrochemical industry, triggered alumina micropowder supports catalysts for refining crude oil. It assists break down big hydrocarbons into fuels like gas. The material resists chemical corrosion. This decreases damages throughout responses. Refineries rely upon it to preserve constant result.

Environmental applications use triggered alumina micropowder to remove toxins. It holds stimulants that convert unsafe gases into much safer substances. Car exhaust systems utilize it to minimize nitrogen oxides and carbon monoxide gas. Manufacturing facilities use it to filter commercial discharges. The powder’s longevity makes certain long-term performance.

Chemical synthesis refines depend on this product for generating specialty chemicals. It sustains stimulants in producing polymers, fertilizers, and drugs. The high porosity allows faster interaction in between reactants and catalysts. This quicken production. Producers save energy and time.

The automobile industry benefits from activated alumina micropowder in catalytic converters. It holds rare-earth elements like platinum and palladium. These metals transform poisonous exhaust gases right into water vapor and co2. The powder’s warmth resistance prevents break down under extreme engine temperature levels.

Drug companies utilize it to sustain stimulants in medicine production. It makes certain accurate responses for pure, top notch products. The product’s inert nature prevents undesirable side reactions. This reliability is important for fulfilling safety and security standards.

Turned on alumina micropowder adapts to various catalytic needs. Its physical and chemical residential properties make it a top option throughout fields. Industries value its cost-effectiveness and performance. The material remains to enable improvements in cleaner power, reliable manufacturing, and environmental management.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Activated Alumina Micropowder as Catalyst Carrier

Activated alumina micropowder serves as a catalyst carrier in industrial processes. Below are five common questions about its role.

What is activated alumina micropowder? It is a porous material made from aluminum oxide. The powder form has high surface area and thermal stability. Its structure allows it to hold catalysts effectively.

Why is it used as a catalyst carrier? It provides a stable base for catalysts. The porous structure spreads catalysts evenly. This improves reaction efficiency. It resists high temperatures and chemical wear.

What benefits does it offer over other materials? It lasts longer than silica or zeolite carriers. The high surface area supports more catalyst loading. It handles harsh conditions without breaking down. Maintenance costs reduce due to durability.

Which industries use it? Petrochemical plants rely on it for refining processes. Environmental applications include air purification systems. Chemical synthesis units use it for producing plastics and fuels.

How should it be stored and handled? Keep it dry before use. Moisture reduces effectiveness. Store in sealed containers away from humidity. Avoid contact with acids or strong alkalis. Proper handling ensures consistent performance.

These points address basic queries about activated alumina micropowder as a catalyst carrier. The material’s properties make it a reliable choice for industrial applications.

(Activated Alumina Micropowder as Catalyst Carrier)