Overview of Activated Alumina Microsphere with Good Thermal Stability

Amphoteric surfactants are a unique class of surface-active agents that possess both cationic and anionic properties, depending on the pH of the system they are in. They contain both a positively charged group (like a quaternary ammonium salt) and a negatively charged group (such as a carboxylate or sulfonate), which can ionize depending on the surrounding conditions. This dual nature grants them exceptional versatility, making them effective in a wide range of pH environments and compatible with other surfactant types. They are known for their mildness and excellent dermatological compatibility, rendering them particularly suitable for personal care applications.

Features of Activated Alumina Microsphere with Good Thermal Stability

-

pH Responsiveness: Their charge varies with pH, becoming cationic in acidic conditions and anionic in alkaline, with a zwitterionic (neutral) state at the isoelectric point.

-

Mildness: Known for being gentle on skin and eyes, making them ideal for sensitive applications like baby care and personal hygiene products.

-

Foaming Properties: Can generate rich, stable foam even in hard water conditions, enhancing their use in cleaning products.

-

Emulsification: Efficient emulsifiers capable of forming both oil-in-water (O/W) and water-in-oil (W/O) emulsions, depending on the formulation and pH.

-

Compatibility: Because they have both anionic and cationic properties, they are compatible with other types of surfactants and can work synergistically to enhance cleaning effects.

-

Biodegradability: Many amphoteric surfactants are readily biodegradable, contributing to their environmentally friendly profile.

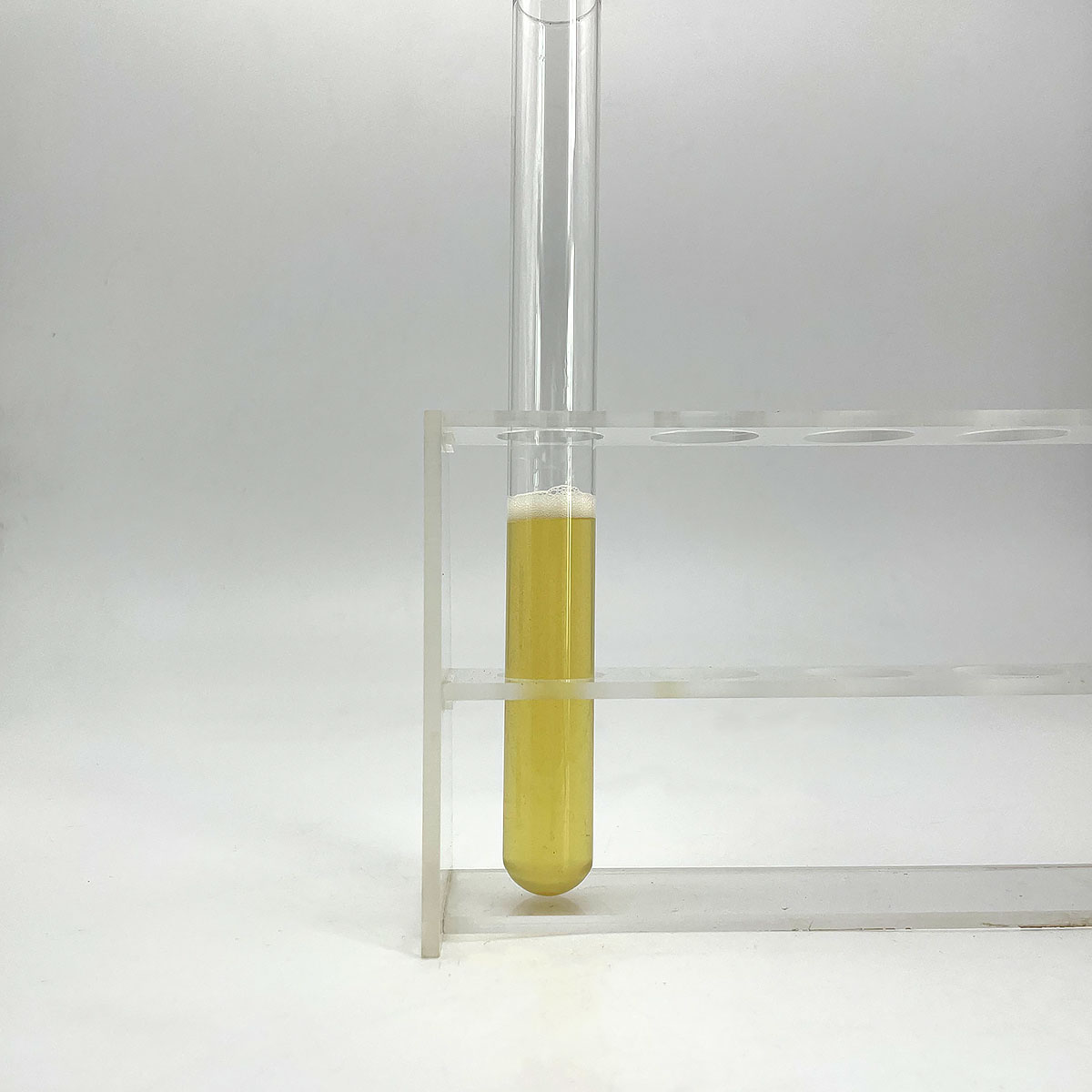

(Activated Alumina Microsphere with Good Thermal Stability)

Specification of Activated Alumina Microsphere with Good Thermal Stability

Triggered alumina microsphere is a high-performance adsorbent material. It is widely made use of in markets like gas drying out, water therapy, and catalysis. The item has a porous framework with several small holes. These openings enhance the area. This makes it effective for capturing dampness and contaminations. The microspheres are made from aluminum oxide. They undergo special therapy to produce their special structure.

The thermal stability of this product is exceptional. It can endure temperatures as much as 600 ° C without breaking down. This makes it appropriate for high-heat environments. The microspheres keep their shape and feature even under severe problems. Their hardness is another advantage. They withstand wear and squashing throughout managing or use.

Fragment size is securely controlled throughout production. Usual dimensions vary from 1 mm to 5 mm in diameter. Uniform dimension makes certain constant efficiency in applications. The material has high adsorption capability. It can hold up to 20% of its weight in water vapor. This makes it perfect for drying procedures. Regeneration is straightforward. Heating the microspheres eliminates entraped dampness for reuse.

Chemical resistance is solid. The product does not respond with many acids, alkalis, or solvents. This prolongs its lifespan in extreme chemical settings. The surface area of the microspheres is large. Regular values vary in between 200-400 m ²/ g. More surface suggests extra energetic websites for adsorption.

Applications include gas drying, where wetness removal is crucial. It is made use of in compressed air systems to stop deterioration. The petrochemical industry utilizes it for detoxifying fluids and gases. Ecological projects utilize it to eliminate fluoride from water. Its thermal security likewise makes it helpful in catalytic procedures requiring warmth.

The product is packaged in moisture-proof containers. Storage conditions are basic. Keep it completely dry and away from direct sunlight. Service life is long if stored properly. No special delivery is required. It is risk-free for commercial use under standard guidelines.

(Activated Alumina Microsphere with Good Thermal Stability)

Applications of Activated Alumina Microsphere with Good Thermal Stability

Turned on alumina microspheres with good thermal stability serve numerous objectives in industries. These tiny, porous particles manage high heat well. This makes them valuable in atmospheres where temperature changes occur frequently. They work as drying representatives for gases and fluids. Their structure takes in moisture without damaging down. This is essential in processes requiring completely dry air or solvents.

The petrochemical market utilizes these microspheres to purify hydrocarbons. They remove pollutants like sulfur compounds from gas. High thermal stability keeps them effective even in warm refining actions. This enhances product quality and safeguards tools.

These microspheres also work as driver carriers. They hold energetic metals or chemicals that quicken reactions. Stable framework makes sure catalysts remain reliable longer under heat. This reduces prices and downtime in chemical production.

Water treatment systems use turned on alumina microspheres to filter contaminants. They catch fluoride, arsenic, and heavy steels from drinking water. Thermal stability lets them take care of hot water streams without shedding performance. This is crucial for risk-free, clean water products.

Insulation products benefit from these microspheres. Their heat resistance makes them suitable for high-temperature insulation. They fill up spaces in commercial stoves, heaters, or pipelines. This lowers energy loss and improves security.

The electronics industry uses them as substrates in sensing units or circuits. Heat resistance avoids damage throughout gadget procedure. This integrity sustains longer-lasting electronic elements.

Medical-grade gases call for stringent dry skin. Triggered alumina microspheres completely dry these gases successfully. Their stability makes certain no fragment breakdown throughout sanitation. This maintains clinical applications risk-free and constant.

These microspheres aid control pollution. They capture unsafe gases like hydrogen sulfide in commercial exhaust. Thermal security allows use in warm exhaust streams. This help conformity with environmental guidelines.

Agriculture uses them to completely dry pesticides or plant foods. Heat resistance stops clumping throughout storage space or transport. This maintains product high quality in varying climates.

Activated alumina microspheres with good thermal security adjust to many needs. Their toughness under warmth makes them a sensible option across fields.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Activated Alumina Microsphere with Good Thermal Stability

Activated alumina microsphere is a porous material made from aluminum oxide. It works well in drying gases and liquids. It removes impurities effectively. Its high surface area boosts adsorption capacity. Thermal stability lets it perform in high-temperature settings without breaking down.

People often ask what activated alumina microsphere does. It mainly adsorbs water and chemicals. It serves as a desiccant in air dryers. It cleans gases in industrial processes. It acts as a catalyst carrier in chemical reactions.

A common question is why thermal stability matters. High heat can damage materials. Activated alumina microsphere keeps its structure even above 500°C. This ensures reliability in harsh conditions. Processes like petroleum refining need this trait.

Many wonder where it gets used. Oil and gas industries rely on it for drying natural gas. Chemical plants use it to purify feedstocks. Environmental projects apply it to filter pollutants. Labs employ it for chromatography.

Handling and storage methods come up often. Keep it dry before use. Moisture exposure reduces effectiveness. Store it in sealed containers. Avoid direct sunlight. Use gloves to prevent contamination.

People ask how it compares to alternatives. Silica gel loses efficiency faster under heat. Molecular sieves cost more for similar jobs. Activated alumina microsphere balances price and performance. It lasts longer in extreme temperatures.

Safety concerns are minimal. It doesn’t react dangerously with most chemicals. Proper handling prevents dust inhalation. Disposal follows standard industrial waste guidelines. No special permits are usually needed.

Durability questions are frequent. It withstands repeated regeneration cycles. Heating it removes trapped moisture. This restores adsorption capacity. Users save money by reusing it multiple times.

Performance varies with particle size. Smaller microspheres adsorb faster. Larger ones handle higher flow rates. Choices depend on specific needs. Manufacturers provide size options for different applications.

Cost factors interest buyers. Production involves controlled calcination. Prices reflect raw material quality and processing. Bulk purchases lower unit costs. Long-term savings come from reuse and efficiency.

Customization options exist. Suppliers adjust pore size and surface area. This tailors performance for specific tasks. Clients share requirements to get optimized products.

Environmental impact is low. It doesn’t release harmful substances. Recycling programs reduce waste. Energy-efficient regeneration supports sustainability goals.

(Activated Alumina Microsphere with Good Thermal Stability)