Overview of Anionic Asphalt Emulsifier for Asphalt Mixture, Bitumen Emulsion

Anionic surfactants are a class of surface-active agents characterized by a negatively charged hydrophilic head group when dissolved in water. This charge arises from the presence of a sulfate, sulfonate, phosphate, or carboxylate group. They are among the most widely used surfactants due to their effective cleaning properties, foaming capacity, and broad compatibility with other formulation ingredients. Anionic surfactants find extensive application across industries, including personal care, household cleaning, textiles, and industrial processes.

Features of Anionic Asphalt Emulsifier for Asphalt Mixture, Bitumen Emulsion

-

Negative Charge: The anionic head group imparts water solubility and enables interaction with positively charged surfaces or particles.

-

Detergency: Exceptional at removing dirt, grease, and oils due to their strong polarity and ability to penetrate and disrupt these substances.

-

Foaming Properties: Many anionic surfactants generate stable and abundant foam, making them ideal for applications where lather is desired.

-

Cost-Effectiveness: They are often less expensive than nonionic, cationic, or amphoteric surfactants due to the abundance of raw materials and established production processes.

-

Compatibility: Can be combined with other surfactants to enhance performance or adjust properties, although care must be taken to avoid precipitation or incompatibility issues.

-

Environmental Considerations: Some anionic surfactants may pose environmental concerns due to their persistence or toxicity; however, biodegradable options are available.

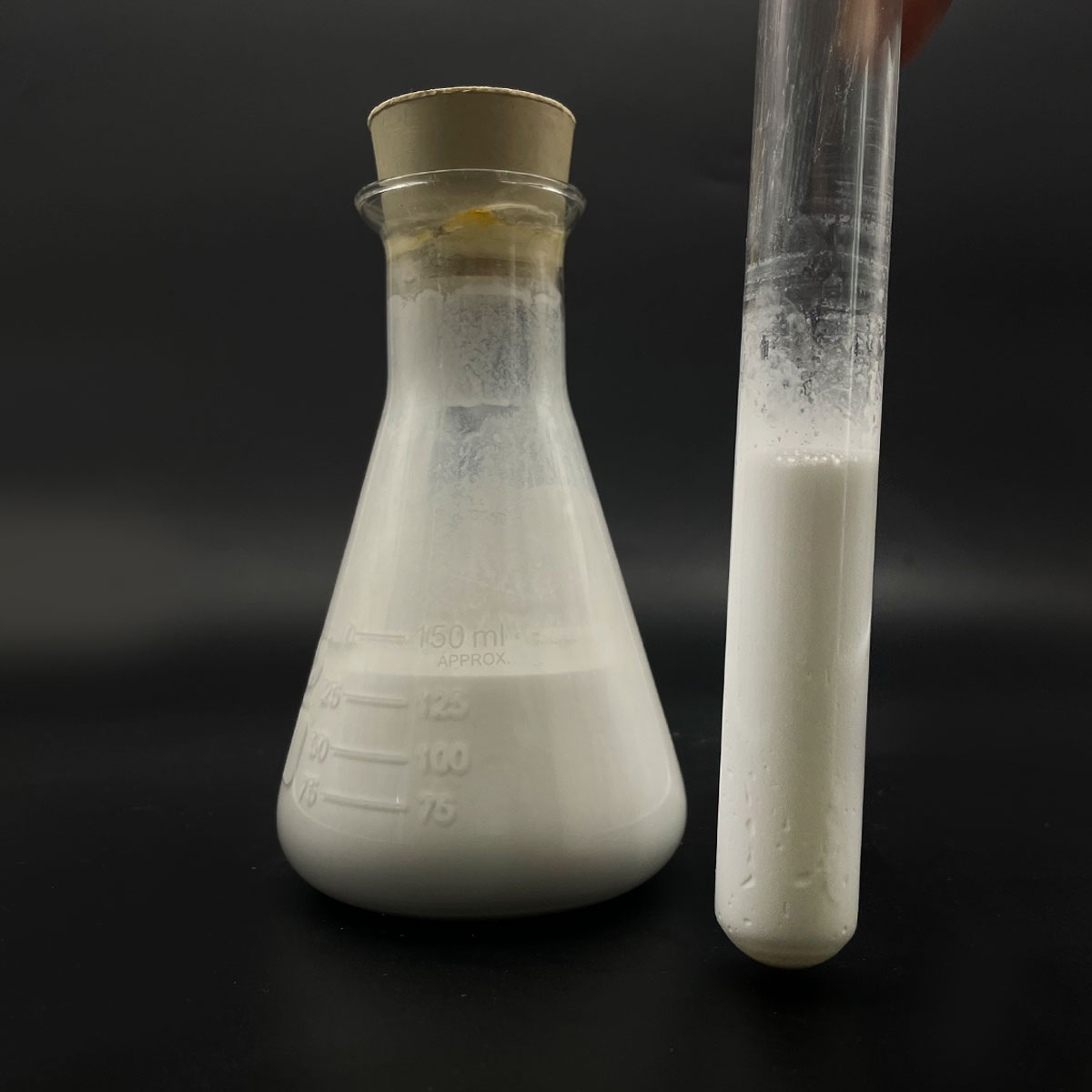

(Anionic Asphalt Emulsifier for Asphalt Mixture, Bitumen Emulsion)

Specification of Anionic Asphalt Emulsifier for Asphalt Mixture, Bitumen Emulsion

Anionic asphalt emulsifier is a vital part in road building. It helps produce secure mixtures of asphalt and water. This item functions as a surfactant. It minimizes surface area stress in between bitumen and water. The result is an uniform solution for various paving applications. The emulsifier is made from natural substances. These are often derived from fats or lignin. The formula makes sure compatibility with various asphalt qualities. It functions well in both cold and hot mix procedures.

The product comes as a liquid. It is simple to deal with and mix. Typical focus ranges from 30% to 50%. The pH degree is alkaline, generally between 10 and 12. This makes sure appropriate emulsification. The emulsifier liquifies completely in water. No residues remain after blending. Storage space requires keeping it in sealed containers. Temperatures need to remain in between 5 ° C and 40 ° C. Direct exposure to direct sunlight has to be avoided.

Application involves including the emulsifier to water first. Asphalt is after that blended in under high shear. The solution forms little asphalt beads suspended in water. This boosts finishing of aggregates. It likewise improves adhesion in the last mix. The emulsifier enables slower splitting times. This gives workers even more time to lay the combination equally. Curing happens faster once the water vaporizes. Roadways end up being traffic-ready sooner.

The emulsifier withstands setting in winter. It protects against splitting in high heat. It works with granite, sedimentary rock, and recycled materials. The item is non-corrosive. It does not damage blending tools. Routine use decreases power prices. It gets rid of the demand for home heating aggregates in some cases.

Safety measures include wearing gloves and safety glasses. Skin get in touch with ought to be washed promptly. Spills have to be had to avoid slipping dangers. The emulsifier is non-flammable. Correct ventilation is still recommended throughout usage.

Life span is up to 6 months when saved correctly. Performance continues to be constant batch-to-batch. Examining fulfills industry criteria for stability and viscosity. The emulsifier is suitable for surface treatments, hole repair services, and full-depth paving. It supports sustainable techniques by reducing gas usage and exhausts.

(Anionic Asphalt Emulsifier for Asphalt Mixture, Bitumen Emulsion)

Applications of Anionic Asphalt Emulsifier for Asphalt Mixture, Bitumen Emulsion

Anionic asphalt emulsifiers play a vital duty in modern roadway building and construction. These chemicals help blend asphalt and water to produce secure asphalt emulsions. Bitumen solutions are commonly made use of for asphalt mixes as a result of their expense effectiveness and environmental advantages. Cold mix asphalt is one typical application. This method utilizes emulsified asphalt to bind aggregates without heating. It conserves power and reduces discharges. Cold mix is excellent for remote locations or little repair services where hot mix plants are not available.

One more major use is chip securing. Emulsifiers ensure the bitumen sticks well to road surface areas and accumulations. This develops a sturdy protective layer. Chip seals protect against water damages and prolong sidewalk life. They are typically used on low-traffic roadways or as maintenance therapies.

Microsurfacing is another application. This method mixes emulsified bitumen with great aggregates and additives. It forms a smooth, wear-resistant surface area. Microsurfacing solutions splits and enhances skid resistance. It is applied quickly and dries quickly, reducing website traffic interruption.

Anionic emulsifiers also boost tack coats. Tack coats boost bond in between old and new asphalt layers. Emulsified asphalt spreads evenly, making certain strong bonds. Appropriate attachment avoids delamination and raises sidewalk resilience.

Asphalt solutions work well in split repair services. Standard hot blends require heavy equipment and high temperatures. Solutions allow cold patching, which is simpler and much faster. Cold spots stay convenient much longer, also in damp conditions. This reduces repair time and expenses.

Environmental benefits make these emulsifiers preferred. Reduced manufacturing temperatures reduced gas usage and greenhouse gases. Decreased fumes enhance employee security. Emulsions also recycle old sidewalk successfully. Recovered asphalt is blended with fresh solution for brand-new roadways. This lowers waste and material prices.

Anionic emulsifiers adjust to various climates. They carry out well in damp or cold problems where warm blends fail. Adjusting the emulsifier formula manages establishing time and thickness. This versatility sustains varied task needs.

In recap, anionic asphalt emulsifiers make it possible for functional, environmentally friendly roadway services. Their applications vary from cool mixes to surface area treatments. These items boost performance, toughness, and sustainability in facilities jobs.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Anionic Asphalt Emulsifier for Asphalt Mixture, Bitumen Emulsion

An anionic asphalt emulsifier is a chemical agent used to mix bitumen with water. It creates a stable emulsion for asphalt mixtures. The emulsifier has a negative charge. This helps it bind better with materials in road construction. It is commonly used in cold mix asphalt. This reduces the need for heating during application.

How does an anionic asphalt emulsifier work? The emulsifier breaks bitumen into tiny droplets. These droplets stay suspended in water. The negative charge on the droplets prevents them from sticking together. This keeps the emulsion stable until it is applied. When the emulsion contacts aggregates, the water evaporates. The bitumen coats the particles. This forms a durable asphalt layer.

What are the benefits of using an anionic asphalt emulsifier? It saves energy. Cold mix asphalt requires less heating. It works well in cooler temperatures. This extends the construction season. The emulsion bonds strongly with many types of aggregates. It is cost-effective. Less fuel is needed for production. It is environmentally friendly. Lower emissions are produced compared to hot mix methods.

How should anionic asphalt emulsifiers be stored? Keep them in sealed containers. Store in a cool, dry place. Avoid direct sunlight. Do not expose to freezing temperatures. Check the expiration date. Use within the recommended period. Always follow the manufacturer’s guidelines. Contamination must be prevented. Use clean equipment when handling.

Is anionic asphalt emulsifier safe to handle? Wear protective gear. Use gloves and goggles. Avoid skin contact. Ensure good ventilation in storage areas. In case of contact, wash with water immediately. Follow safety data sheets for specific instructions. Proper handling minimizes risks. Dispose of waste according to local regulations.

(Anionic Asphalt Emulsifier for Asphalt Mixture, Bitumen Emulsion)