Overview of Compound High-Efficiency Polyether Modified Silicone Defoamer for Printing Ink (DF630)

Specialty surfactants are a diverse class of surface-active agents designed for specific, high-performance applications where standard surfactants may not meet the required performance criteria. These surfactants are often tailor-made to exhibit unique properties, such as extreme temperature stability, low foam formation, high solubility in specific solvents, or compatibility with particular chemical systems. They are crucial components in formulations demanding precision, enhanced functionality, or strict regulatory compliance, found across industries from pharmaceuticals to advanced materials manufacturing.

Features of Compound High-Efficiency Polyether Modified Silicone Defoamer for Printing Ink (DF630)

-

Customized Performance: Developed to meet exacting specifications, offering tailored functionalities beyond generic surfactants.

-

High Efficiency: Designed to work at lower concentrations or under challenging conditions, increasing performance per unit mass.

-

Unique Properties: May exhibit special traits such as non-flammability, low toxicity, high thermal stability, or specific solubility profiles.

-

Regulatory Compliance: Often formulated to meet stringent industry-specific regulations, such as food-grade, medical, or eco-friendly standards.

-

Innovative Chemistry: Incorporate novel chemistries, such as fluorinated, silicone-based, or bio-based structures, to achieve specialized performance.

-

Synergistic Effects: Frequently used in combination with other surfactants to enhance or augment performance in complex formulations.

(Compound High-Efficiency Polyether Modified Silicone Defoamer for Printing Ink (DF630))

Specification of Compound High-Efficiency Polyether Modified Silicone Defoamer for Printing Ink (DF630)

DF630 is a high-performance defoamer designed specifically for printing ink applications. This compound formula uses advanced polyether modified silicone technology. It targets foam issues during ink production and printing processes. Foam causes problems like uneven coating and surface defects. This product eliminates existing foam quickly. It also prevents new foam from forming.

The defoamer works across various ink systems. It performs well in solvent-based inks. It is equally effective in water-based formulations. Compatibility is a key advantage. DF630 integrates smoothly without causing haze or separation. It maintains ink clarity and gloss. Print quality stays consistent.

Efficiency sets this defoamer apart. Low dosage rates deliver strong results. Typical usage ranges from 0.1% to 0.5% of total ink weight. Stability under different temperatures is reliable. The product remains effective over time. It does not impact ink drying speed. Color development stays true.

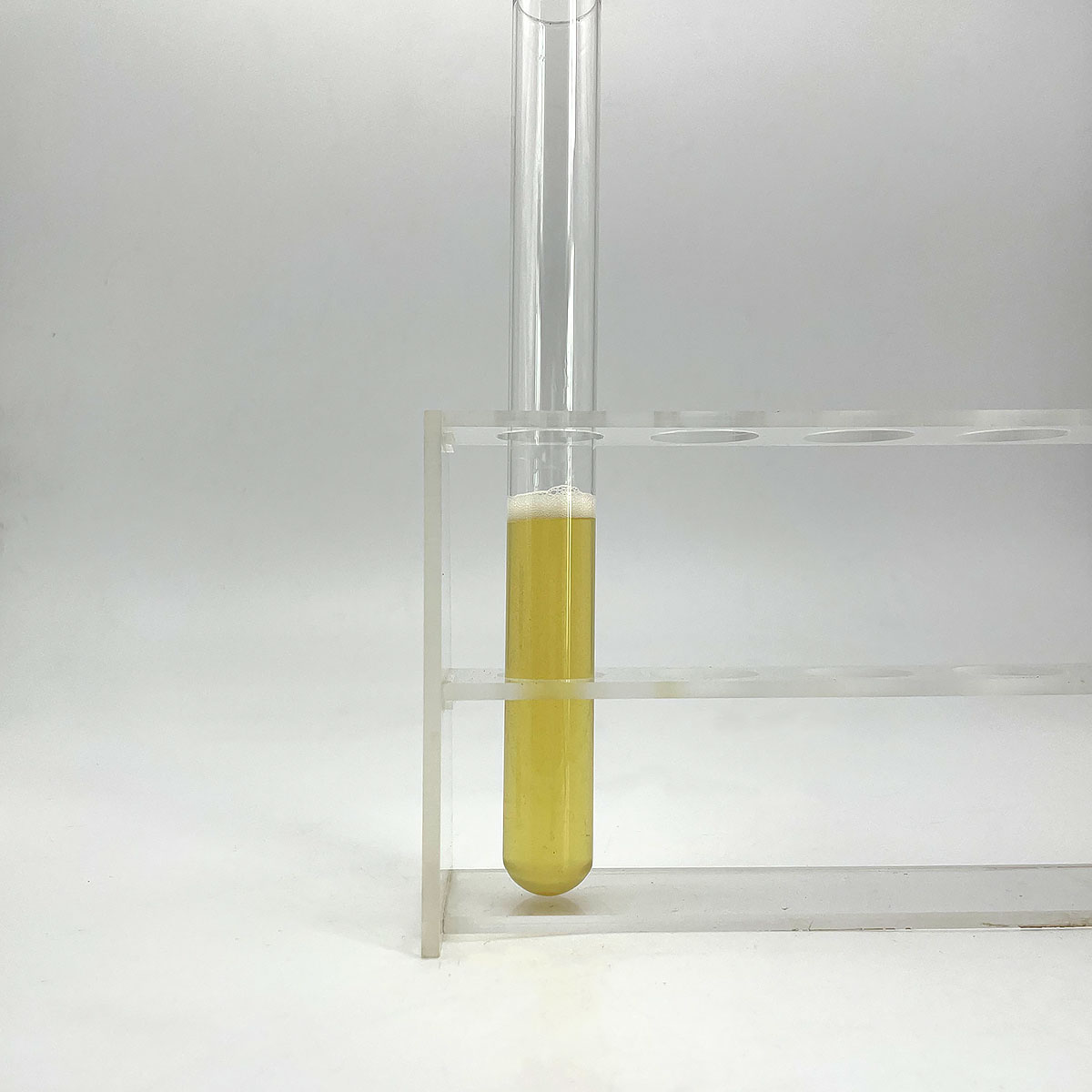

Physical properties are straightforward. DF630 appears as a milky white emulsion. Active content measures approximately 20%. Viscosity is moderate. pH levels are neutral, usually between 6 and 8. The product is non-toxic. It meets environmental safety standards.

Packaging comes in standard industrial sizes. Options include 25-kilogram plastic drums and 200-kilogram iron drums. Storage requires a cool, dry environment. Avoid freezing conditions. Shelf life is one year from production date.

Application timing is flexible. Add DF630 during ink manufacturing. Incorporate it when foam appears during printing. Adjust dosage based on foam severity. Testing helps determine optimal levels.

(Compound High-Efficiency Polyether Modified Silicone Defoamer for Printing Ink (DF630))

Applications of Compound High-Efficiency Polyether Modified Silicone Defoamer for Printing Ink (DF630)

DF630 is a compound high-efficiency defoamer designed specifically for printing inks. It uses a special polyether modified silicone base. This combination tackles tough foam problems effectively. Foam causes big issues during printing. It leads to uneven ink application, pinholes, and poor print quality. You need a reliable solution. DF630 works quickly. It breaks down bubbles fast. It prevents new bubbles from forming. This keeps your ink system clean. Printers see smoother ink transfer onto materials. You get consistent color and sharp images. Waste from defects goes down. Production efficiency improves.

DF630 excels in various printing processes. It works very well in flexographic printing. Flexo inks often foam during high-speed runs. DF630 controls this reliably. It prevents bubble marks on labels and packaging films. Gravure printing also benefits. Foam in the ink trays causes problems. DF630 eliminates this foam. It ensures smooth ink pickup by the cylinders. Water-based inks are common. They foam easily due to their nature. DF630 handles this challenge perfectly. It keeps water-based systems stable. UV-curable inks can foam too. DF630 performs well here without affecting cure speed.

The product integrates easily into ink formulations. It disperses well. You won’t see oil spots or craters on the printed surface. It maintains its effectiveness over time. It works across different press speeds. It handles temperature changes well. Printers value its long-lasting performance. DF630 is compatible with most ink chemistries. This makes it a versatile choice. Using DF630 means fewer print defects. It means less downtime cleaning presses. It means higher quality output consistently. The result is better productivity and lower costs for your printing operation.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Compound High-Efficiency Polyether Modified Silicone Defoamer for Printing Ink (DF630)

What is DF630? DF630 is a compound high-efficiency polyether modified silicone defoamer. It tackles foam in printing inks. This product prevents bubbles during production and application. How does DF630 work? It breaks foam quickly. The formula reduces surface tension. Bubbles collapse fast. New foam formation stops. This keeps ink processes smooth. What benefits does DF630 offer? It performs at low dosages. This cuts costs. Foam control lasts long. Ink color stays true. Gloss remains unaffected. It blends easily. No negative impact on ink quality happens. How should DF630 be added? Mix it during ink manufacturing. Add it while combining ingredients. Use 0.1% to 0.5% by weight. Stir thoroughly. Ensure even distribution. This method gives best results. Is DF630 compatible with all ink types? Yes. It works with water-based inks. It handles solvent-based systems. UV-curable inks pose no problem. Flexographic and gravure printing benefit. No compatibility issues arise.

(Compound High-Efficiency Polyether Modified Silicone Defoamer for Printing Ink (DF630))