Overview of Cosil Methyl RTV 107 Oh Silicone Polymer 750CS 1000CS 2000CS 5000CS 20000CS 50000CS 80000CS Oh Silicone Polymer

Polymer surfactants, also known as polymeric surfactants or amphiphilic polymers, are high-molecular-weight compounds that combine the properties of traditional low-molecular-weight surfactants with the unique features of polymers. Unlike small molecule surfactants, polymer surfactants offer enhanced stability, improved solubility, and the ability to form more complex structures such as micelles, hydrogels, and vesicles. These macromolecules find applications across a wide range of industries due to their tailored structures and tunable properties, which allow for precise control over interfacial behavior and solution rheology.

Features of Cosil Methyl RTV 107 Oh Silicone Polymer 750CS 1000CS 2000CS 5000CS 20000CS 50000CS 80000CS Oh Silicone Polymer

-

Molecular Weight and Structure: With a much higher molecular weight, polymer surfactants offer enhanced stability in harsh conditions and over prolonged periods compared to small molecule surfactants.

-

Tunability: The structure of polymer surfactants can be precisely engineered to include different functional groups, monomer sequences, and architectures, allowing for specific interactions and properties.

-

Multifunctionality: Apart from surface activity, they can also provide additional functionalities like thickening, rheology modification, and controlled release capabilities.

-

Self-Assembly: Capable of forming sophisticated self-assembled structures like micelles, hydrogels, and vesicles, which can encapsulate or release active ingredients in a controlled manner.

-

Environmental Compatibility: Many polymer surfactants are designed to be biodegradable and less toxic, making them suitable for eco-friendly applications.

-

Temperature and pH Responsiveness: Some polymer surfactants exhibit responsive behavior to changes in temperature or pH, enabling stimuli-responsive systems.

(Cosil Methyl RTV 107 Oh Silicone Polymer 750CS 1000CS 2000CS 5000CS 20000CS 50000CS 80000CS Oh Silicone Polymer)

Specification of Cosil Methyl RTV 107 Oh Silicone Polymer 750CS 1000CS 2000CS 5000CS 20000CS 50000CS 80000CS Oh Silicone Polymer

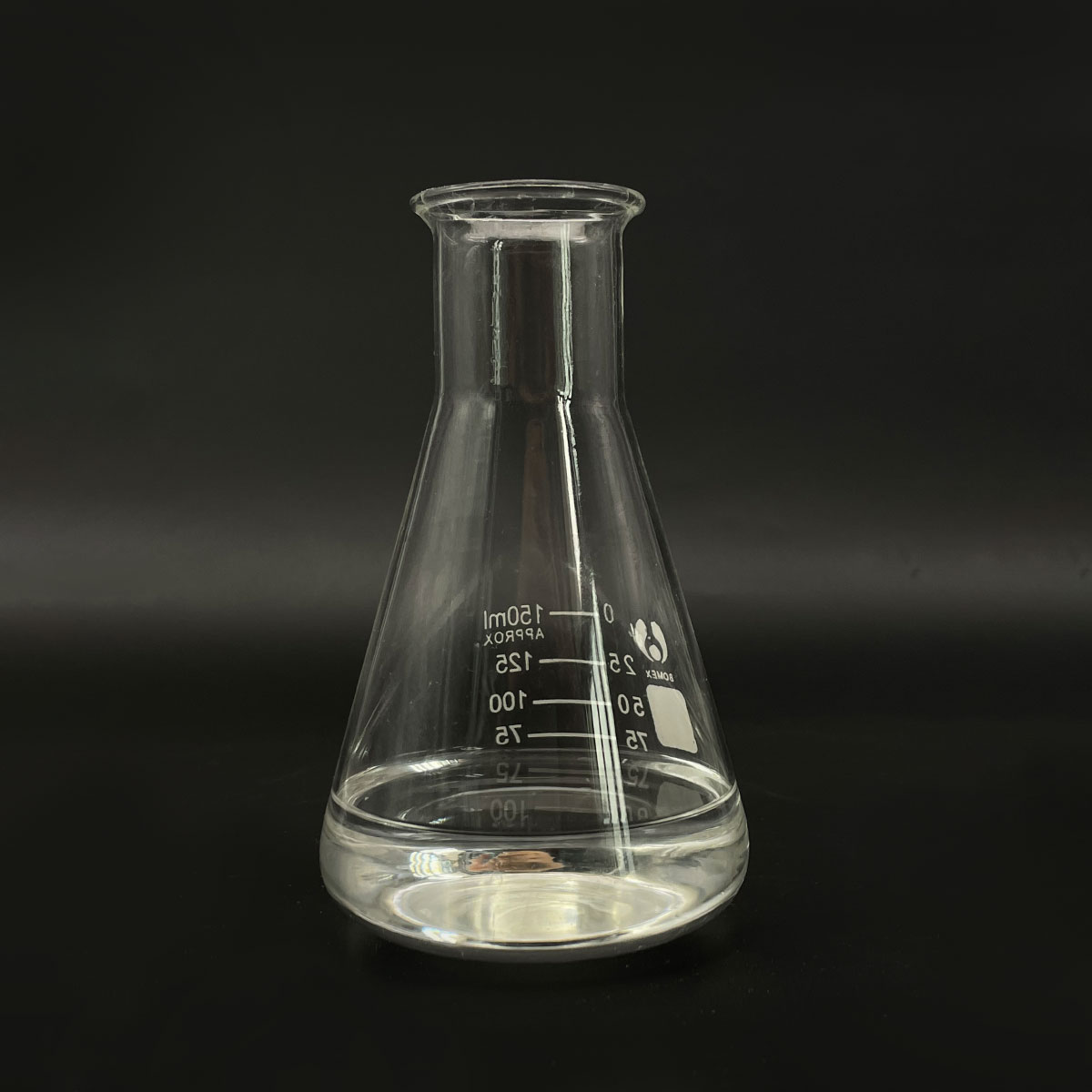

Cosil Methyl RTV 107 silicone polymer is a high-performance material utilized in lots of industrial and business applications. The product is offered in various viscosity grades, including 750CS, 1000CS, 2000CS, 5000CS, 20000CS, 50000CS, and 80000CS. Each quality offers special circulation residential properties to match certain requirements. Reduced viscosity qualities like 750CS and 1000CS are thinner, making them ideal for finishing fragile surface areas or filling little spaces. Higher thickness grades like 20000CS and 80000CS are thicker, appropriate for molding, securing, or producing long lasting rubber parts.

This silicone polymer treatments at area temperature, creating a flexible, rubber-like product. It bonds well with steels, plastics, glass, and ceramics without needing primers or unique treatments. The healed product resists extreme temperatures, staying stable between -50 ° C and 200 ° C. It also manages moisture, UV exposure, and chemicals without breaking down.

Cosil Methyl RTV 107 is widely utilized in electronics for shielding circuits, potting parts, or protecting cords. Automotive sectors rely upon it for gaskets, seals, and vibration-dampening components. Industrial upkeep groups utilize it to fix devices or produce personalized molds. The silicone stays versatile after healing, stopping cracks under stress and anxiety.

The product is secure to handle before curing. It has reduced volatility and gives off marginal smell. Individuals should adhere to common security techniques, like wearing gloves and working in ventilated areas. As soon as healed, the silicone comes to be non-toxic and secure for skin contact.

Various thickness options permit individuals to choose the right consistency for their projects. Thin grades spread out easily for smooth surfaces. Thick grades remain in area for upright applications or heavy-duty seals. The silicone preserves its residential or commercial properties over time, ensuring lasting integrity.

Cosil Methyl RTV 107 is packaged in secured containers to stop premature treating. Storage space in amazing, completely dry conditions extends life span. Technical support is offered to help select the most effective grade for particular demands.

(Cosil Methyl RTV 107 Oh Silicone Polymer 750CS 1000CS 2000CS 5000CS 20000CS 50000CS 80000CS Oh Silicone Polymer)

Applications of Cosil Methyl RTV 107 Oh Silicone Polymer 750CS 1000CS 2000CS 5000CS 20000CS 50000CS 80000CS Oh Silicone Polymer

Cosil Methyl RTV 107 silicone polymer comes in several thickness grades like 750CS, 1000CS, 2000CS, 5000CS, 20000CS, 50000CS, and 80000CS. Each grade offers certain commercial demands. The lower-viscosity grades, like 750CS and 1000CS, work well for thin finishings or filling small spaces. These are usually used in electronics for safeguarding circuit boards or protecting wires. The fluid uniformity allows easy application without leaving air pockets.

The medium-viscosity qualities, such as 2000CS and 5000CS, balance circulation and thickness. These prevail in automobile parts like gaskets or seals. The material stays adaptable under heat or vibration. It withstands oil, chemicals, and climate changes. This makes it dependable for engines or outside equipment.

Higher-viscosity choices like 20000CS and 50000CS suit sturdy usages. They create durable barriers in industrial equipment. These grades deal with high-pressure problems. They stop leaks in pumps or shutoffs. The thicker uniformity stays in location without dripping.

The greatest qualities, like 80000CS, imitate paste. They fill big voids or fixing used surfaces. Building and construction projects use this for securing joints in concrete or metal structures. It bonds highly to a lot of materials. It remedies at area temperature level, conserving energy.

Cosil Methyl RTV 107 withstands severe temperature levels. It remains steady from -50 ° C to 200 ° C. This makes it helpful in aerospace or a/c systems. The silicone polymer does not degrade under UV exposure. It lasts longer outdoors compared to routine rubbers.

Medical devices make use of particular grades for safe seals. The product satisfies safety and security standards. It does not respond with medications or bodily liquids. Labs apply it for waterproofing delicate tools.

Manufacturers choose various viscosities based upon precision needs. Slim grades cover fragile parts without adding mass. Thick qualities sustain architectural repair services. The item adapts to several sectors. It decreases downtime by preventing leakages or insulation failures.

Users appreciate the easy application. No special tools are required. It cures quickly, quickening production. The silicone polymer stays flexible gradually. It avoids fracturing or diminishing. Maintenance costs drop due to its durability.

Custom-made solutions are readily available for distinct difficulties. The variety of viscosities ensures versatility. Services rely on it for constant efficiency. It satisfies rigorous quality requirements.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Cosil Methyl RTV 107 Oh Silicone Polymer 750CS 1000CS 2000CS 5000CS 20000CS 50000CS 80000CS Oh Silicone Polymer

Cosil Methyl RTV 107 Oh Silicone Polymer is a versatile material used in many industries. Below are answers to common questions about its grades (750CS, 1000CS, 2000CS, 5000CS, 20000CS, 50000CS, 80000CS).

What is this silicone polymer used for?

It works for coatings, sealants, lubricants, and mold-making. Different viscosities suit different needs. Thin grades like 750CS spread easily. Thick grades like 80000CS stay in place for heavy-duty applications.

How do I pick the right viscosity?

Thinner grades flow better for coatings or filling gaps. Thicker grades handle sealing or cushioning. Match the viscosity to your project’s needs. Think about how it will be applied.

Is it safe to use?

It is non-toxic and solvent-free. Follow safety guidelines. Wear gloves. Work in a ventilated area. Avoid skin contact. Check the safety sheet for details.

Can I mix different grades?

Mixing grades adjusts viscosity. Test small batches first. Make sure the base materials are compatible. Mixing might affect curing time or performance.

How long does it last?

Unopened containers last about 12 months. Store it in a cool, dry place. Keep lids tight. Check for changes in texture or smell before using old stock.

These answers cover basic use cases. Always test the product for specific projects. Refer to technical documents for detailed data.

(Cosil Methyl RTV 107 Oh Silicone Polymer 750CS 1000CS 2000CS 5000CS 20000CS 50000CS 80000CS Oh Silicone Polymer)