Overview of Experienced Original Factory Supply Dispersible Polymer Powder Rdp for Dry Powder Coating

Polymer surfactants, also known as polymeric surfactants or amphiphilic polymers, are high-molecular-weight compounds that combine the properties of traditional low-molecular-weight surfactants with the unique features of polymers. Unlike small molecule surfactants, polymer surfactants offer enhanced stability, improved solubility, and the ability to form more complex structures such as micelles, hydrogels, and vesicles. These macromolecules find applications across a wide range of industries due to their tailored structures and tunable properties, which allow for precise control over interfacial behavior and solution rheology.

Features of Experienced Original Factory Supply Dispersible Polymer Powder Rdp for Dry Powder Coating

-

Molecular Weight and Structure: With a much higher molecular weight, polymer surfactants offer enhanced stability in harsh conditions and over prolonged periods compared to small molecule surfactants.

-

Tunability: The structure of polymer surfactants can be precisely engineered to include different functional groups, monomer sequences, and architectures, allowing for specific interactions and properties.

-

Multifunctionality: Apart from surface activity, they can also provide additional functionalities like thickening, rheology modification, and controlled release capabilities.

-

Self-Assembly: Capable of forming sophisticated self-assembled structures like micelles, hydrogels, and vesicles, which can encapsulate or release active ingredients in a controlled manner.

-

Environmental Compatibility: Many polymer surfactants are designed to be biodegradable and less toxic, making them suitable for eco-friendly applications.

-

Temperature and pH Responsiveness: Some polymer surfactants exhibit responsive behavior to changes in temperature or pH, enabling stimuli-responsive systems.

(Experienced Original Factory Supply Dispersible Polymer Powder Rdp for Dry Powder Coating)

Specification of Experienced Original Factory Supply Dispersible Polymer Powder Rdp for Dry Powder Coating

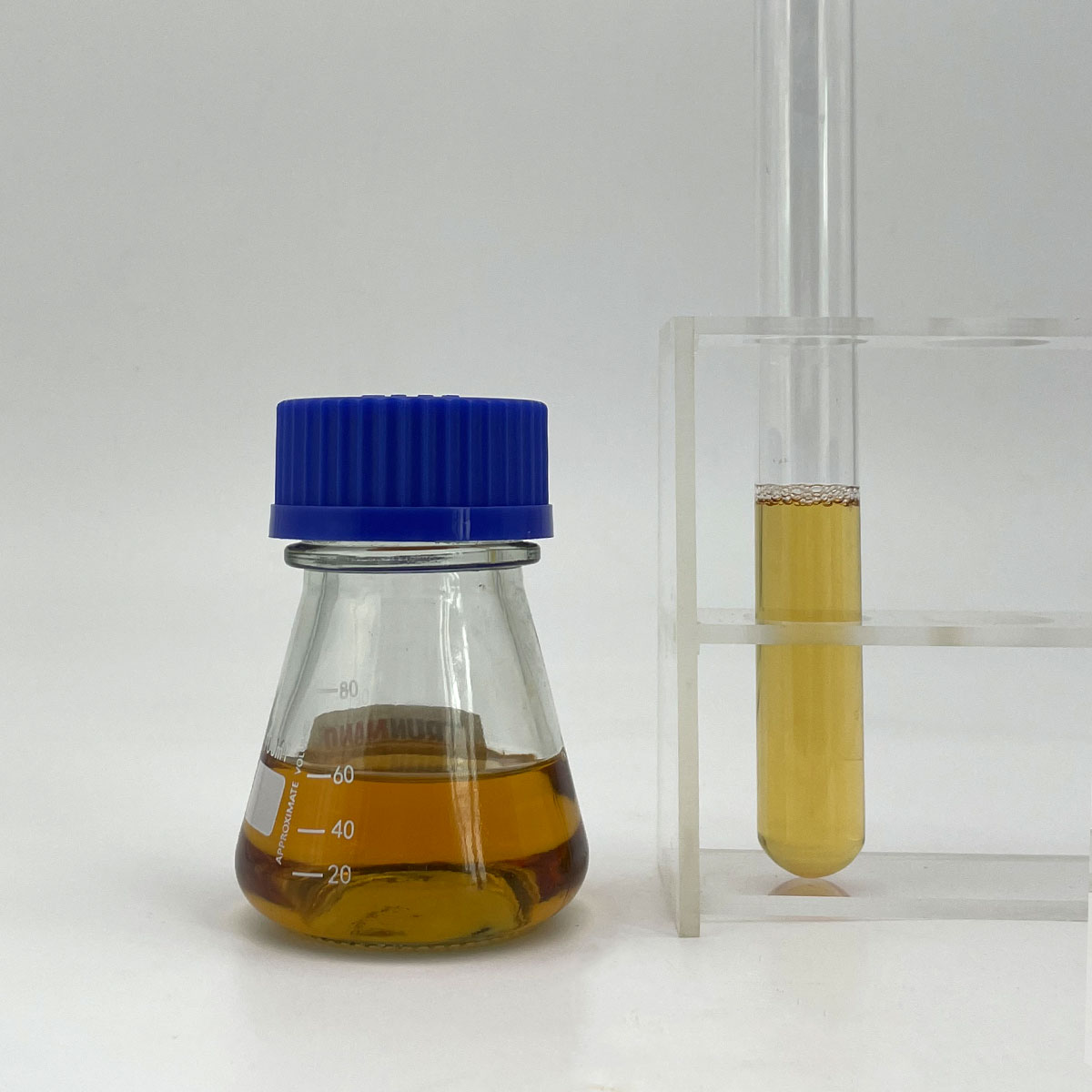

This product is a top notch dispersible polymer powder designed for dry powder finishing applications. It is produced by a knowledgeable original factory with advanced technology and strict quality assurance. The powder offers excellent water-redispersibility, bond, and versatility. It improves the efficiency of dry-mix materials by boosting communication, workability, and longevity.

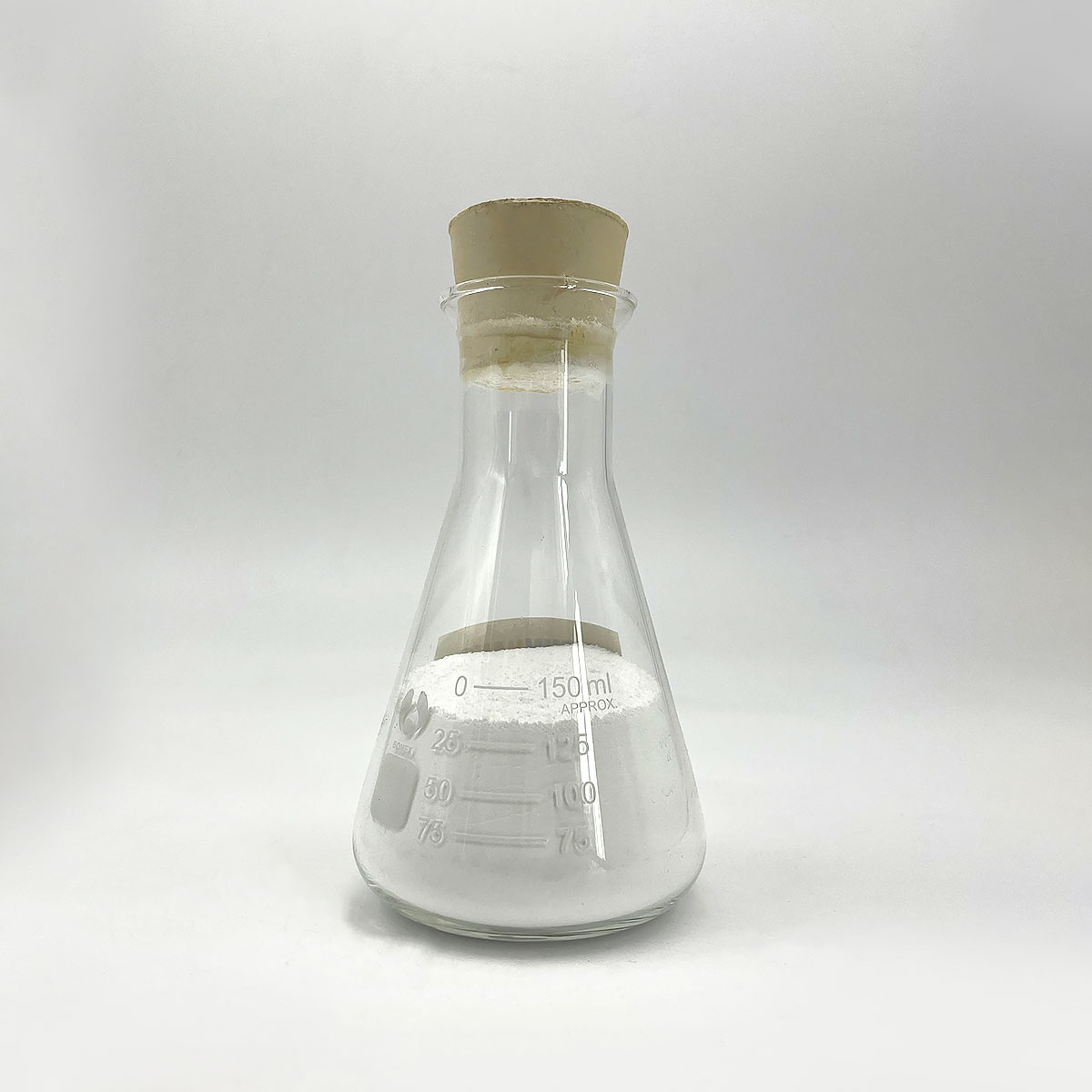

The polymer powder is made from a vinyl acetate-ethylene copolymer base. It is free-flowing and white in look. The bit dimension varies in between 80 and 120 microns for optimal blending and dispersion. The powder dissolves rapidly in water, forming a stable solution that integrates seamlessly with concrete, gypsum, and other binders. This makes sure uniform distribution in the final mix.

Secret requirements consist of a strong content of 98% or greater and a mass density of 400-500 kg/m FIVE. The minimum film-forming temperature is 0 ° C, enabling use in diverse environments. The ash content after calcination is below 14%, ensuring high polymer purity. The powder’s thickness in service remains in between 500 and 3000 mPa · s for consistent application. The pH degree is neutral (6-8), stopping rust or reactivity with other products.

This item is optimal for completely dry powder coverings in building products like tile adhesives, self-leveling substances, and exterior insulation systems. It improves fracture resistance, water resistance, and effect stamina. The powder lowers dust development during blending and application, improving workplace safety and security. It is compatible with cellulose ethers and various other additives, permitting adaptable solution adjustments.

The manufacturing facility makes certain steady supply and customizable bit dimension or structure options. Product packaging consists of 25 kg moisture-proof paper bags or bulk containers for huge orders. Storage space recommendations include maintaining the powder in a cool, dry place far from direct sunshine. Life span is one year under appropriate conditions.

Applications reach ornamental plaster, putty powders, and repair work mortars. The polymer improves open time, adhesion, and surface end up quality. It meets international standards for ecological security, consisting of no hazardous solvents or hefty steels. Performance examinations validate compliance with ASTM, ISO, and EN standards. Technical assistance is available for product selection and troubleshooting.

(Experienced Original Factory Supply Dispersible Polymer Powder Rdp for Dry Powder Coating)

Applications of Experienced Original Factory Supply Dispersible Polymer Powder Rdp for Dry Powder Coating

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Experienced Original Factory Supply Dispersible Polymer Powder Rdp for Dry Powder Coating

What is dispersible polymer powder RDP?

Dispersible polymer powder RDP is a free-flowing white powder made from polymer materials. It dissolves easily in water to form a stable emulsion. This powder improves the performance of dry powder coatings by enhancing adhesion, flexibility, and water resistance. It works well in construction and industrial applications.

Why use RDP in dry powder coatings?

RDP increases the durability and workability of dry powder coatings. It helps coatings stick better to surfaces, even in humid conditions. The powder reduces cracking and peeling over time. It also makes mixing easier by preventing clumps. This saves time and improves product quality.

Where is RDP commonly applied?

RDP is used in tile adhesives, exterior insulation systems, self-leveling compounds, and repair mortars. It suits both indoor and outdoor projects. Factories prefer it for industrial coatings on metal, concrete, and plaster surfaces. The powder adapts to different climates and temperatures.

Is RDP safe to handle?

RDP is non-toxic and environmentally friendly when used correctly. Wear gloves and masks to avoid inhaling dust during handling. Keep the powder away from direct moisture to prevent clumping. Follow local safety guidelines for storage and disposal.

How should RDP be stored?

Store RDP in a cool, dry place away from sunlight. Use sealed containers to block moisture and air. Avoid stacking bags too high to prevent compression. Proper storage keeps the powder usable for up to 12 months. Check for lumps before use—discard if hardened.

(Experienced Original Factory Supply Dispersible Polymer Powder Rdp for Dry Powder Coating)