Overview of Flake Silver Powder for Conductive Adhesive for Solar Cells

Specialty surfactants are a diverse class of surface-active agents designed for specific, high-performance applications where standard surfactants may not meet the required performance criteria. These surfactants are often tailor-made to exhibit unique properties, such as extreme temperature stability, low foam formation, high solubility in specific solvents, or compatibility with particular chemical systems. They are crucial components in formulations demanding precision, enhanced functionality, or strict regulatory compliance, found across industries from pharmaceuticals to advanced materials manufacturing.

Features of Flake Silver Powder for Conductive Adhesive for Solar Cells

-

Customized Performance: Developed to meet exacting specifications, offering tailored functionalities beyond generic surfactants.

-

High Efficiency: Designed to work at lower concentrations or under challenging conditions, increasing performance per unit mass.

-

Unique Properties: May exhibit special traits such as non-flammability, low toxicity, high thermal stability, or specific solubility profiles.

-

Regulatory Compliance: Often formulated to meet stringent industry-specific regulations, such as food-grade, medical, or eco-friendly standards.

-

Innovative Chemistry: Incorporate novel chemistries, such as fluorinated, silicone-based, or bio-based structures, to achieve specialized performance.

-

Synergistic Effects: Frequently used in combination with other surfactants to enhance or augment performance in complex formulations.

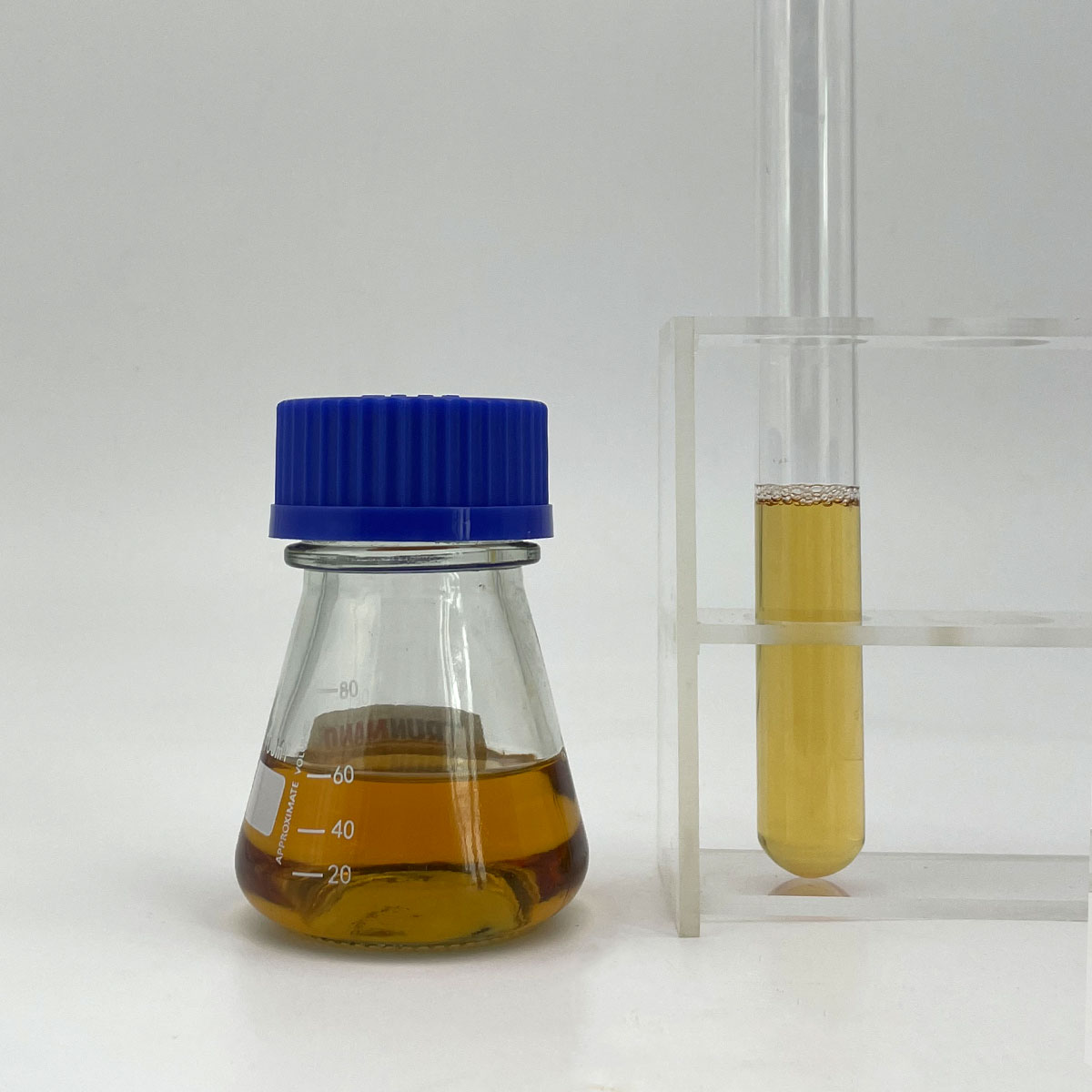

(Flake Silver Powder for Conductive Adhesive for Solar Cells)

Specification of Flake Silver Powder for Conductive Adhesive for Solar Cells

This flake silver powder is designed for conductive adhesives in solar batteries. It aids create solid electrical connections. The powder conducts power well. It is shaped like tiny flat flakes. This flake shape is essential. It lets the particles touch each other conveniently within the adhesive paste. Excellent call means better electrical energy flow. The level shape additionally assists the paste stick well to the solar cell surfaces.

Particle size is carefully controlled. The ordinary size falls within a specific range. We make sure most particles are near this ordinary size. Regular dimension helps the powder mix uniformly right into the adhesive. It protects against clumping. This gives a smooth paste for screen printing. The paste uses uniformly onto the solar battery fingers and busbars.

Area matters as well. The flakes have a high surface area. This large surface assists the powder conduct effectively. It additionally improves how the powder bonds with the sticky material. Excellent bonding makes the last connection solid and dependable.

A special covering is related to the flake surface areas. This coating is natural. It stops the silver flakes from sticking together before usage. It maintains the powder moving openly. The coating burn cleanly throughout the solar battery curing process. It leaves no harmful residues behind. This keeps the electrical connection pure.

Pureness is extremely high. The silver content meets rigorous criteria. Reduced degrees of contaminations are ensured. High pureness ensures very little electrical resistance. It stops corrosion with time. This protects the long-lasting efficiency of the solar cell.

The powder’s tap density and noticeable thickness are enhanced. This influences exactly how the powder crams in the paste. It influences the paste’s final thickness and conductivity after treating. The right thickness guarantees the printed lines are dense and conductive. They carry the electrical power the solar battery creates effectively.

This powder enables conductive adhesives that form durable, low-resistance electric courses. It sustains effective solar energy collection and power output.

(Flake Silver Powder for Conductive Adhesive for Solar Cells)

Applications of Flake Silver Powder for Conductive Adhesive for Solar Cells

Flake silver powder matters a lot for conductive adhesives in solar cells. These adhesives connect components inside solar panels. They need to bring power well. Flake silver powder is ideal for this work. Its unique shape is the key. The fragments are flat and thin, like little scales. This shape lets them overlap tightly. Great overlap develops numerous paths for electrical energy to flow. Electrical energy relocates easily via the adhesive. This is important for solar cell efficiency. Much better conductivity means less energy shed as warm. Much more sunshine obtains developed into usable electrical energy.

Making use of flake silver powder makes the glue more powerful also. The flakes lock together. This produces a difficult network inside the adhesive. The bond stays trusted for a very long time. Solar panels deal with challenging problems outdoors. Heat, chilly, and humidity can harm products. Adhesives with flake silver powder resist these stresses better. They aid the solar panel last much longer.

Manufacturers also like flake silver powder. It blends smoothly right into the glue paste. This paste is very easy to apply exactly. Workers can print fine lines exactly where needed. This precision is important for modern, high-efficiency solar batteries. Less silver powder is needed to get excellent conductivity. This saves money. Silver is pricey. Decreasing the quantity made use of decreases costs. It keeps the final photovoltaic panel price affordable. Flake silver powder delivers regular outcomes batch after batch. Production stays trustworthy. The glue carries out predictably. This dependability is essential for massive solar panel manufacturing.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Flake Silver Powder for Conductive Adhesive for Solar Cells

Here are 5 FAQs about Flake Silver Powder for Conductive Adhesive in Solar Cells:

Why use flake silver powder in solar cell adhesive?

Flake silver powder is vital. It makes the adhesive conduct electricity. This connects the solar cell parts. Round powder shapes don’t connect as well. Flakes touch more. This helps electricity flow better. It makes the solar cell work efficiently.

How does the flake shape help performance?

The flat shape is key. Flakes stack like tiles. They create many contact points. Electricity moves easily across these points. This lowers resistance. Lower resistance means less energy loss. Your solar cell produces more power.

Will this powder work with my adhesive type?

Yes, it usually works. Flake silver powder mixes well with common adhesives. These include epoxies and silicones. The powder disperses evenly. This keeps conductivity high. Always test with your specific adhesive formula first. This ensures the best results.

How much silver powder is needed?

You need the right amount. Too little powder won’t conduct well. Too much makes the adhesive thick. It becomes hard to apply. The best amount depends on the adhesive and application. Typically, 70% to 85% silver by weight works well. Follow your supplier’s guidelines closely.

Is the powder stable over time?

Yes, it is designed for stability. Good flake silver powder resists oxidation. Oxidation reduces conductivity. Reputable suppliers use protective coatings. These coatings prevent tarnishing. This keeps performance consistent. Store the powder properly. Keep it sealed and cool. This extends its shelf life.

(Flake Silver Powder for Conductive Adhesive for Solar Cells)