Overview of Fluorinated Surfactant Excellent Wetting and Leveling Agents

Polymer surfactants, also known as polymeric surfactants or amphiphilic polymers, are high-molecular-weight compounds that combine the properties of traditional low-molecular-weight surfactants with the unique features of polymers. Unlike small molecule surfactants, polymer surfactants offer enhanced stability, improved solubility, and the ability to form more complex structures such as micelles, hydrogels, and vesicles. These macromolecules find applications across a wide range of industries due to their tailored structures and tunable properties, which allow for precise control over interfacial behavior and solution rheology.

Features of Fluorinated Surfactant Excellent Wetting and Leveling Agents

-

Molecular Weight and Structure: With a much higher molecular weight, polymer surfactants offer enhanced stability in harsh conditions and over prolonged periods compared to small molecule surfactants.

-

Tunability: The structure of polymer surfactants can be precisely engineered to include different functional groups, monomer sequences, and architectures, allowing for specific interactions and properties.

-

Multifunctionality: Apart from surface activity, they can also provide additional functionalities like thickening, rheology modification, and controlled release capabilities.

-

Self-Assembly: Capable of forming sophisticated self-assembled structures like micelles, hydrogels, and vesicles, which can encapsulate or release active ingredients in a controlled manner.

-

Environmental Compatibility: Many polymer surfactants are designed to be biodegradable and less toxic, making them suitable for eco-friendly applications.

-

Temperature and pH Responsiveness: Some polymer surfactants exhibit responsive behavior to changes in temperature or pH, enabling stimuli-responsive systems.

(Fluorinated Surfactant Excellent Wetting and Leveling Agents)

Specification of Fluorinated Surfactant Excellent Wetting and Leveling Agents

Fluorinated surfactants stand out as high-performance wetting and progressing agents. These items work by lowering surface area stress in fluids. This allows finishes, inks, or adhesives to spread out equally throughout surface areas. The outcome is smooth surfaces without issues like pinholes or craters.

The chemical structure includes fluorine-based chains. These chains develop solid repellency against oils, water, and impurities. The surfactants stay stable in extreme problems. They do well under high temperatures or acidic environments. Their low concentration need makes them cost-efficient.

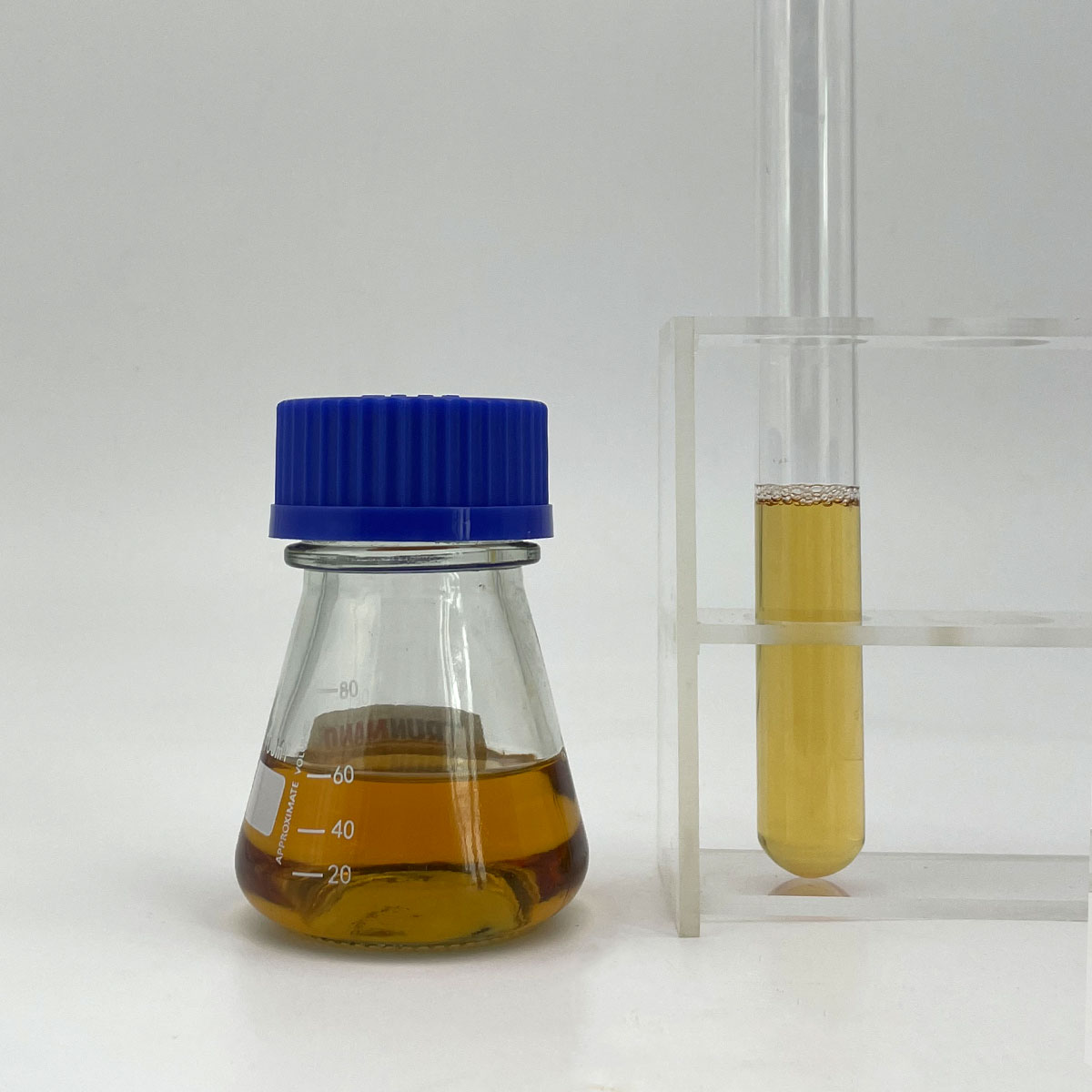

Secret specs cover physical and chemical homes. The active ingredient material typically varies from 20% to 50%. Appearance is typically a clear, light-yellow liquid. pH levels stay neutral, between 6 and 8. Solubility varies with the formula. Many versions blend conveniently with water or natural solvents.

Efficiency advantages focus on rate and consistency. Quick wetting action makes sure fast insurance coverage of substratums. This reduces handling time in commercial applications. Leveling properties avoid uneven drying out or movie formation. Compatibility with various other additives is a priority. The surfactants integrate efficiently right into existing systems without causing splitting up.

Applications cover multiple markets. In paints and coatings, they improve gloss and attachment. Electronics making utilizes them to improve circuit card finishes. Textile treatments rely upon their capacity to repel stains. Automotive ends up achieve higher toughness.

Security and managing comply with conventional procedures. Proper ventilation is advised during use. Direct skin get in touch with ought to be stayed clear of. Storage space calls for great, completely dry problems to maintain stability. Shelf life expands up to 2 years if unopened.

These surfactants satisfy regulative standards for commercial use. Certifications consist of REACH and ISO conformity. Environmental effect is lessened via biodegradable options. Customized formulas are offered for certain demands. Technical support guarantees optimal integration right into production procedures.

(Fluorinated Surfactant Excellent Wetting and Leveling Agents)

Applications of Fluorinated Surfactant Excellent Wetting and Leveling Agents

Fluorinated surfactants are essential components in many commercial and customer products. Their unique properties make them excellent for enhancing wetting and leveling. These representatives lower surface tension properly. This allows fluids to spread out evenly throughout surfaces. The result is a smooth, defect-free surface.

In layers and paints, fluorinated surfactants ensure uniform application. They help the fluid cover substrates swiftly. This protects against issues like craters or pinholes. These defects usually originate from bad wetting. The surfactants work well in water-based and solvent-based systems. They maintain performance even at reduced concentrations. This makes them affordable for manufacturers.

The electronic devices market benefits from these surfactants. They are utilized in published circuit boards and semiconductor layers. Precise wetting is crucial below. Fluorinated surfactants assist create also layers on complex components. This stays clear of electrical failings caused by unequal insurance coverage. Their security under heats adds worth.

Cleaning up items depend on fluorinated surfactants for far better infiltration. They assist remedies get to dust caught in little areas. This boosts stain elimination without hefty scrubbing. Their ability to reduced surface stress enhances cleaning effectiveness. They execute well in extreme conditions. Acidic or alkaline atmospheres do not weaken their efficiency.

Textile manufacturing usages these surfactants to deal with textiles. They help dyes in spreading evenly. This leads to dynamic, constant shades. The process works on synthetic and all-natural fibers. Water repellency is one more benefit. Dealt with materials resist discolorations better.

Fluorinated surfactants are flexible. They adapt to different markets without losing performance. Their chemical framework gives sturdiness. This makes certain resilient impacts in final products. Makers trust them for dependable results. The balance of effectiveness and economy makes them a preferred option.

Ecological aspects are taken into consideration in their development. Modern fluorinated surfactants objective to minimize environmental impact. They satisfy regulative criteria internationally. Security profiles are improved for employees and end-users. This focus on sustainability lines up with industry trends.

Fluorinated surfactants remain to develop. New applications emerge as innovation breakthroughs. Their duty in enhancing item quality remains unmatched. Industries acknowledge their value in attaining high-performance outcomes.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Fluorinated Surfactant Excellent Wetting and Leveling Agents

What are fluorinated surfactants? Fluorinated surfactants are specialty chemicals containing fluorine atoms. They reduce surface tension in liquids. This makes liquids spread more evenly on surfaces. They work better than regular surfactants in many cases. Their unique structure allows strong performance at low concentrations.

How do fluorinated surfactants improve wetting? These surfactants lower surface tension quickly. This lets liquids cover surfaces faster and more completely. Even on hard-to-wet materials like plastics or metals, they help avoid defects. The result is a smooth, even coating without streaks or gaps.

Why choose fluorinated surfactants over traditional options? Fluorinated versions work at much lower doses. They stay effective in acidic or high-temperature environments. Regular surfactants might break down under these conditions. Fluorinated types also resist evaporation and organic solvents. This makes them last longer in tough applications.

Where are these surfactants typically used? They are common in paints, coatings, and industrial cleaners. Electronics manufacturing uses them for precise circuit board coatings. Textile treatments and firefighting foams also rely on their fast-spreading action. Any industry needing reliable surface coverage uses fluorinated surfactants.

Are fluorinated surfactants safe? Most are designed to meet strict safety standards. They often have low toxicity levels when handled correctly. Environmental impact depends on specific formulas. Many newer versions break down faster to reduce ecological harm. Always check safety sheets and follow local disposal rules.

(Fluorinated Surfactant Excellent Wetting and Leveling Agents)