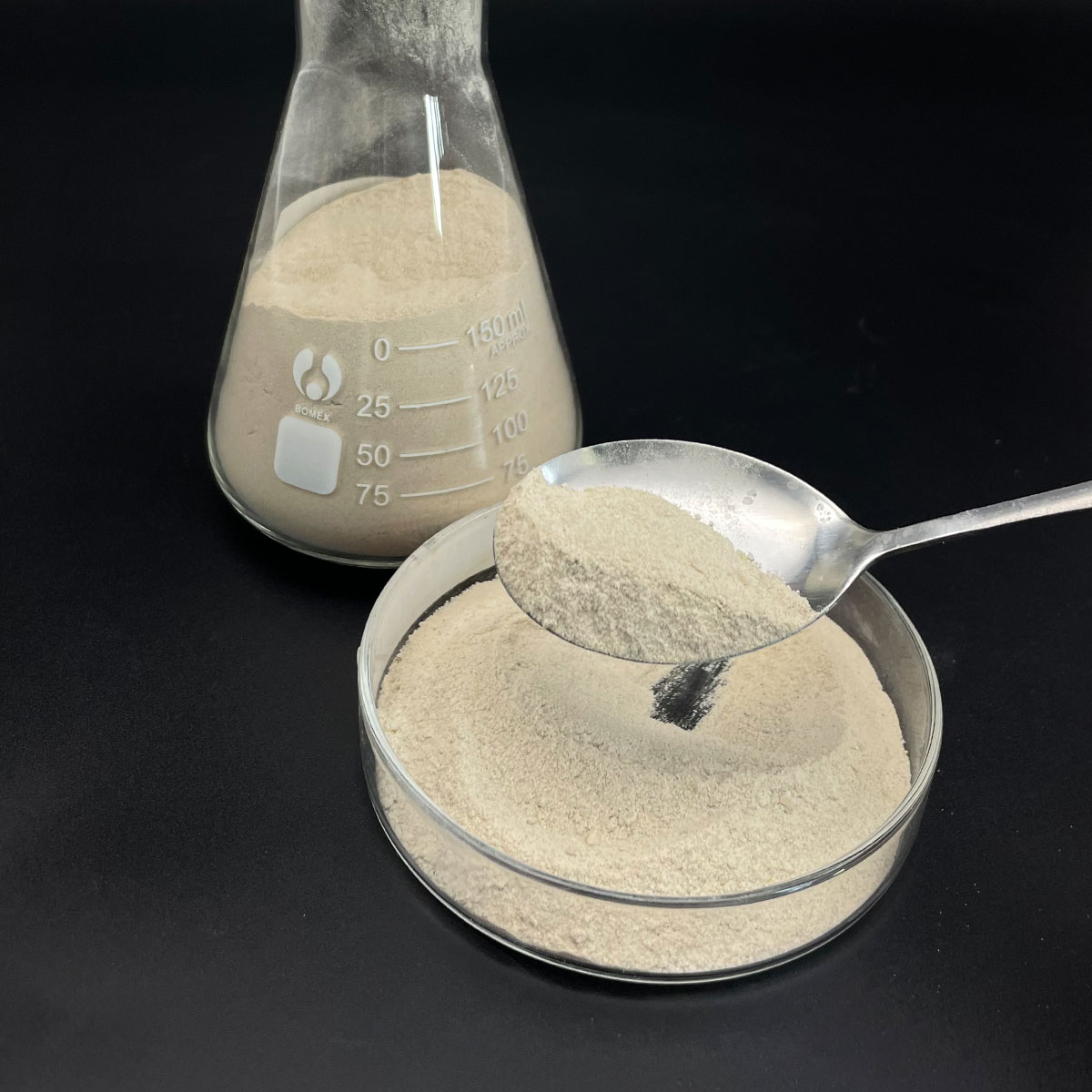

Overview of High Concentration Pre-Dispersion PVC Masterbatch Powder All Types of Platics

Specialty surfactants are a diverse class of surface-active agents designed for specific, high-performance applications where standard surfactants may not meet the required performance criteria. These surfactants are often tailor-made to exhibit unique properties, such as extreme temperature stability, low foam formation, high solubility in specific solvents, or compatibility with particular chemical systems. They are crucial components in formulations demanding precision, enhanced functionality, or strict regulatory compliance, found across industries from pharmaceuticals to advanced materials manufacturing.

Features of High Concentration Pre-Dispersion PVC Masterbatch Powder All Types of Platics

-

Customized Performance: Developed to meet exacting specifications, offering tailored functionalities beyond generic surfactants.

-

High Efficiency: Designed to work at lower concentrations or under challenging conditions, increasing performance per unit mass.

-

Unique Properties: May exhibit special traits such as non-flammability, low toxicity, high thermal stability, or specific solubility profiles.

-

Regulatory Compliance: Often formulated to meet stringent industry-specific regulations, such as food-grade, medical, or eco-friendly standards.

-

Innovative Chemistry: Incorporate novel chemistries, such as fluorinated, silicone-based, or bio-based structures, to achieve specialized performance.

-

Synergistic Effects: Frequently used in combination with other surfactants to enhance or augment performance in complex formulations.

(High Concentration Pre-Dispersion PVC Masterbatch Powder All Types of Platics)

Specification of High Concentration Pre-Dispersion PVC Masterbatch Powder All Types of Platics

High Focus Pre-Dispersion PVC Masterbatch Powder is made for tinting and boosting performance in PVC and various other plastics. This item makes sure even circulation of pigments and ingredients. It collaborates with inflexible and adaptable PVC applications. The powder type simplifies handling and blending. It decreases dust throughout handling. This enhances workplace safety and security.

The masterbatch consists of high levels of energetic components. This decreases the amount required per batch. It conserves prices without compromising top quality. The pre-dispersed formula avoids clumping. It makes sure consistent color and properties in the final product. The powder is compatible with the majority of plastic kinds. These consist of polyethylene, polypropylene, ABS, and more.

Particle dimension is managed for smooth integration. This stays clear of problems like touches or places. Thermal security permits use in high-temperature handling. It works in extrusion, shot molding, and calendaring. The product resists fading under UV exposure. It preserves shade vibrancy in exterior applications.

Custom formulas are available. Adjustments can be created details solidity, gloss, or mechanical requirements. The masterbatch supports adding practical ingredients. These include anti-static representatives, fire retardants, or anti-oxidants. It fits industries like vehicle parts, wires, flooring, and product packaging.

Storage space is straightforward. Keep the powder in a dry, awesome location. Wetness security guarantees lengthy shelf life. No unique tools is needed for blending. Standard mixers or mixers attain consistent results. Examining is suggested for brand-new applications. Little tests validate compatibility and effect.

The product fulfills global safety and security and ecological standards. It makes use of non-toxic, heavy-metal-free pigments. Conformity with REACH and RoHS is ensured. Set consistency is ensured via stringent quality assurance. Technical support is attended to fixing or optimization.

This masterbatch reduces production time. It eliminates actions like premixing pigments. Energy use drops as a result of reliable diffusion. Waste is decreased via specific dosing. The outcome is a trustworthy, cost-efficient solution for industrial plastic manufacturing.

(High Concentration Pre-Dispersion PVC Masterbatch Powder All Types of Platics)

Applications of High Concentration Pre-Dispersion PVC Masterbatch Powder All Types of Platics

High concentration pre-dispersion PVC masterbatch powder works as a crucial material for modifying plastics. It mixes evenly into PVC and various other plastic bases. This produces steady color impacts and boosted efficiency. Makers use it widely since it simplifies production. The powder’s high pigment lots decreases the amount needed. This cuts costs and increases efficiency.

The building sector relies on this item for products like pipes, window profiles, and roof covering sheets. It includes UV resistance and weatherproofing. These attributes aid products last longer outdoors. The vehicle market uses it for indoor components like dashboards and door panels. The powder makes certain consistent shade and stops fading under warmth or sunshine.

Durable goods benefit as well. Products like playthings, house home appliances, and footwear gain bright, durable colors. The masterbatch avoids clumping throughout handling. This maintains surfaces smooth and defect-free. Adaptable packaging materials likewise use this powder. It maintains quality and strength in films and wraps while adding customized tones.

The electronic devices market applies it for cord insulation and wiring coverings. The product stands up to warmth and chemical damages. This safeguards delicate elements. Medical devices use it for tubing and casings. The powder satisfies stringent security standards. It prevents releasing unsafe compounds.

Customization is easy. Individuals pick from a large range of shades and additives. Choices include anti-static or flame-retardant homes. The pre-dispersed design saves time. Manufacturing facilities miss added blending steps. This speeds up production cycles.

Ecological benefits exist. Much less waste happens as a result of accurate application. Energy make use of declines since handling temperature levels remain reduced. Recycled plastics mix well with the masterbatch. This supports green production.

The item fits all plastic kinds. It works in shot molding, extrusion, and impact molding. Small and large-scale operations both achieve reliable outcomes. Compatibility with additives like stabilizers or fillers keeps formulas versatile.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of High Concentration Pre-Dispersion PVC Masterbatch Powder All Types of Platics

High Concentration Pre-Dispersion PVC Masterbatch Powder is a specialized additive for enhancing plastic products. It mixes evenly into various plastics, providing color or functional properties. Below are common questions about this product.

What is High Concentration Pre-Dispersion PVC Masterbatch Powder?

This powder is a concentrated blend of pigments or additives pre-dispersed in a PVC carrier. It simplifies coloring or modifying plastics during production. The high concentration reduces the amount needed, lowering costs.

Which plastics work with this masterbatch?

It works with all plastic types. Common examples include PVC, polyethylene, polypropylene, and polystyrene. The pre-dispersion formula ensures compatibility. No extra steps are required for most applications.

What advantages does it offer over traditional methods?

Traditional methods need separate mixing of raw materials. This masterbatch skips that step. It saves time and reduces errors. The high concentration cuts material use. Color consistency improves, and waste decreases.

How is the masterbatch applied during manufacturing?

Mix the powder directly with the base resin before processing. The ratio depends on the desired effect. Typical usage ranges from 1% to 5% of the total mix. Follow the supplier’s guidelines for optimal results.

Are there safety concerns with handling this product?

Standard safety practices apply. Wear gloves and masks to avoid inhaling particles. Store it in a dry, cool place away from sunlight. Processed plastics are safe for regular use.

This product streamlines plastic manufacturing. It ensures consistent quality while reducing costs. Manufacturers across industries rely on it for efficient production.

(High Concentration Pre-Dispersion PVC Masterbatch Powder All Types of Platics)