Overview of High Performance Anionic Wetting Agent Surfactant for Paints

Anionic surfactants are a class of surface-active agents characterized by a negatively charged hydrophilic head group when dissolved in water. This charge arises from the presence of a sulfate, sulfonate, phosphate, or carboxylate group. They are among the most widely used surfactants due to their effective cleaning properties, foaming capacity, and broad compatibility with other formulation ingredients. Anionic surfactants find extensive application across industries, including personal care, household cleaning, textiles, and industrial processes.

Features of High Performance Anionic Wetting Agent Surfactant for Paints

-

Negative Charge: The anionic head group imparts water solubility and enables interaction with positively charged surfaces or particles.

-

Detergency: Exceptional at removing dirt, grease, and oils due to their strong polarity and ability to penetrate and disrupt these substances.

-

Foaming Properties: Many anionic surfactants generate stable and abundant foam, making them ideal for applications where lather is desired.

-

Cost-Effectiveness: They are often less expensive than nonionic, cationic, or amphoteric surfactants due to the abundance of raw materials and established production processes.

-

Compatibility: Can be combined with other surfactants to enhance performance or adjust properties, although care must be taken to avoid precipitation or incompatibility issues.

-

Environmental Considerations: Some anionic surfactants may pose environmental concerns due to their persistence or toxicity; however, biodegradable options are available.

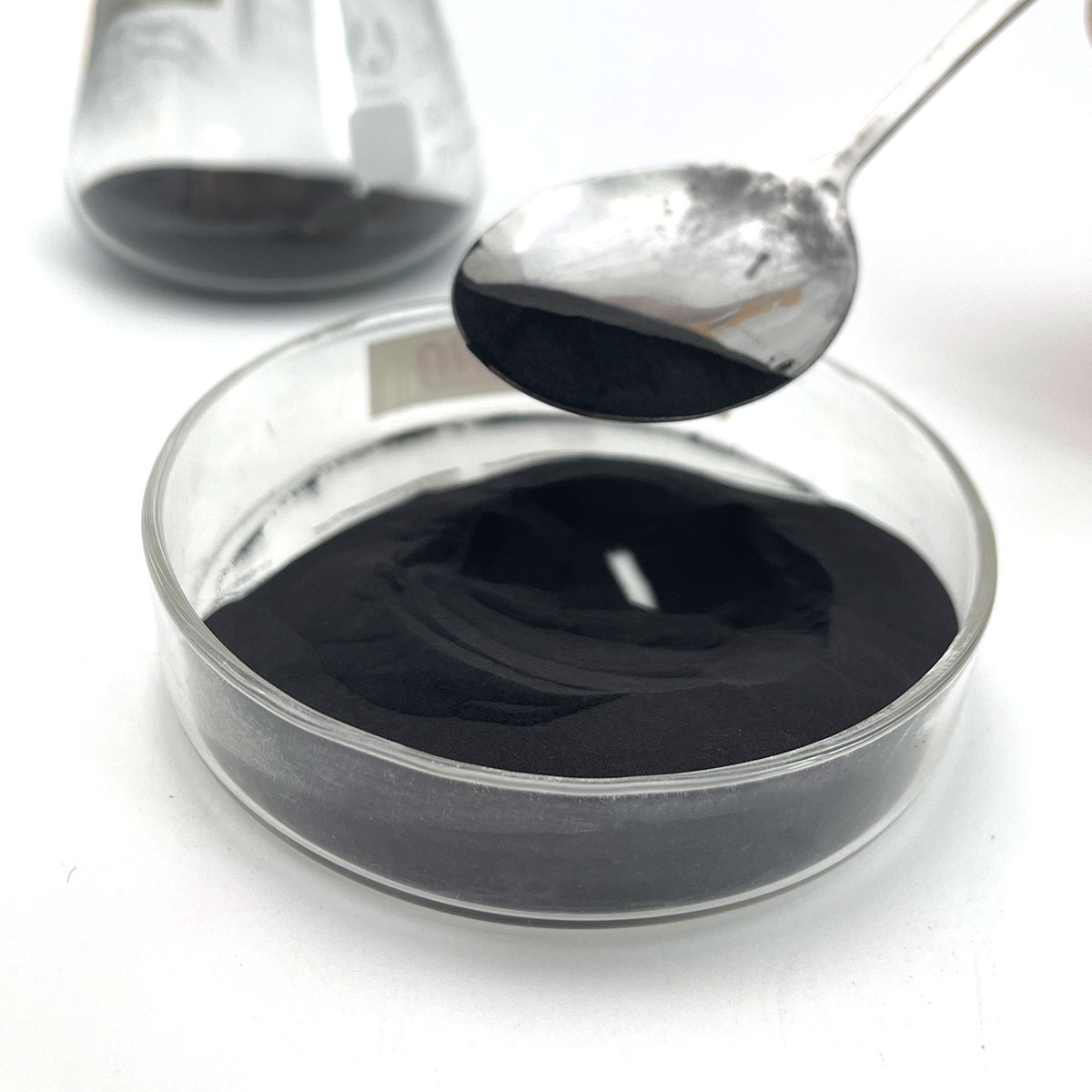

(High Performance Anionic Wetting Agent Surfactant for Paints)

Specification of High Performance Anionic Wetting Agent Surfactant for Paints

This high-performance anionic wetting agent surfactant is developed for use in paint formulations. It enhances surface insurance coverage, decreases surface stress, and improves substrate wetting. The product makes certain uniform paint application on difficult surfaces like metals, plastics, and heavily distinctive products. It works efficiently in water-based and solvent-based systems.

The surfactant has a strong focus of 40-45%, guaranteeing stability in high-pH environments. Its reduced foam generation reduces defects throughout high-speed blending or spraying. The formula resizes pigment dispersion, preventing settling or clumping. This causes regular color circulation and long-term storage stability.

Compatibility with various other additives like thickeners and defoamers is a crucial function. The product preserves performance throughout a wide temperature variety, from 5 ° C to 50 ° C. It is without alkylphenol ethoxylates (APEO) and unstable natural substances (VOCs), straightening with worldwide ecological criteria.

The surfactant decreases the demand for extreme stirring or rework during manufacturing. It cuts drying out time by improving fluid circulation throughout substratums. This boosts manufacturing effectiveness and reduces power prices. The representative appropriates for commercial layers, auto paints, and architectural surfaces.

Users gain from enhanced attachment on low-energy surface areas like polyethylene and polypropylene. The product minimizes cratering and fisheye flaws caused by contamination. Its ionic nature makes sure fast adsorption onto surfaces, creating a steady film.

Dosage recommendations vary from 0.2% to 1.5% of total paint weight, relying on substrate complexity. Overuse does not compromise movie honesty or water resistance. The surfactant remains reliable in electrolyte-rich atmospheres, common in aquatic or anticorrosive finishings.

Storage space needs a cool, completely dry area with temperatures in between 10 ° C and 30 ° C. Life span is twelve month in unopened containers. The item is packaged in 25kg and 200kg plastic drums for industrial usage.

Testing validates conformity with ISO 9001 and REACH regulations. Technical support is available for formulation modifications and troubleshooting.

(High Performance Anionic Wetting Agent Surfactant for Paints)

Applications of High Performance Anionic Wetting Agent Surfactant for Paints

High-performance anionic wetting agent surfactants for paints boost exactly how fluids spread out and stick to surface areas. These ingredients reduced surface tension in paint solutions. This aids coverings cover materials uniformly without leaving gaps or bubbles. The outcome is a smooth coating on wall surfaces, metal, plastic, or timber.

These surfactants function well in water-based paints. They help water blend with pigments and resins more effectively. This protects against clumps or unequal shade in the final product. They also reduce foam during mixing or spraying. Much less foam indicates fewer problems like pinholes or craters on dried paint layers.

In industrial layers, anionic wetting agents boost adhesion on difficult surfaces like oily steel or dusty concrete. They allow the covering penetrate little splits or pores. This creates a stronger bond in between the paint and substratum. It likewise withstands peeling or flaking with time.

Architectural paints take advantage of these surfactants as well. They help achieve constant textures in indoor or exterior jobs. Brushes or rollers glide less complicated during application. Drying times remain predictable also in humid problems. This decreases brush marks or lap lines on walls.

Producers add these agents during production. They maintain the formula so it does the same batch after set. The surfactants protect against splitting up in storage space. This prolongs service life without influencing thickness or color.

High-performance versions manage harsh conditions. They work in extreme pH levels or heats. This fits them for specialized layers like fireproof paints or sturdy epoxy systems. They maintain performance without breaking down chemically.

These additives support environment-friendly paint growth. They cut the need for added solvents or harmful chemicals. Reduced VOC levels fulfill stringent environmental guidelines. They remain effective in low-concentration doses. This minimizes material costs and waste.

Anionic wetting representatives improve scrape resistance in completely dry paint movies. They aid pigments line up evenly as coverings heal. This develops a denser, harder surface area that lasts longer. The result shows up in high-traffic areas like floors or outside furnishings.

Wood layers obtain benefits too. The surfactants let spots penetrate deeper right into grain patterns. This improves all-natural appearances without blotchiness. They additionally obstruct resin from leaking out of knots in fresh lumber.

Printing inks use comparable technology. The surfactants make certain sharp details on paper, plastic films, or packaging products. Shades stay vivid without bleeding or fading after drying.

Metal guides count on these representatives to avoid corrosion. They press moisture far from the substrate during application. This quits corrosion prior to the topcoat seals the surface.

The surfactants adapt to computerized painting systems. They keep spray guns or rollers from blocking. This quicken assembly line while reducing downtime for cleaning.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of High Performance Anionic Wetting Agent Surfactant for Paints

High Performance Anionic Wetting Agent Surfactant for Paints solves common issues in paint formulations. Below are answers to frequent questions.

What does this surfactant do?

It helps paints spread evenly on surfaces. It lowers the liquid’s surface tension. This prevents uneven drying or patchy spots. It works well in water-based paints.

Why pick an anionic type?

Anionic surfactants carry a negative charge. This improves mixing with other paint ingredients. They stay stable in alkaline conditions common in paint formulas. They cost less than nonionic options but perform similarly.

Can it work with other additives?

Yes. It blends with thickeners, defoamers, and pigments. Test small batches first. Check for changes in texture or color. Adjust ratios if separation or clumping happens.

How much should be used?

Add 0.1% to 0.5% of the total paint weight. Start low. Increase slowly if needed. Too much causes foaming or weakens the paint film. Follow supplier guidelines for your specific formula.

Is it safe to handle?

Wear gloves and goggles when mixing. Avoid skin or eye contact. Store in a cool, dry place. Keep away from kids and pets. Check safety data sheets for disposal rules.

(High Performance Anionic Wetting Agent Surfactant for Paints)