Overview of High Quality Powder Flake Monochloroacetic Acid Flake Chloroacetic Acid

Amphoteric surfactants are a unique class of surface-active agents that possess both cationic and anionic properties, depending on the pH of the system they are in. They contain both a positively charged group (like a quaternary ammonium salt) and a negatively charged group (such as a carboxylate or sulfonate), which can ionize depending on the surrounding conditions. This dual nature grants them exceptional versatility, making them effective in a wide range of pH environments and compatible with other surfactant types. They are known for their mildness and excellent dermatological compatibility, rendering them particularly suitable for personal care applications.

Features of High Quality Powder Flake Monochloroacetic Acid Flake Chloroacetic Acid

-

pH Responsiveness: Their charge varies with pH, becoming cationic in acidic conditions and anionic in alkaline, with a zwitterionic (neutral) state at the isoelectric point.

-

Mildness: Known for being gentle on skin and eyes, making them ideal for sensitive applications like baby care and personal hygiene products.

-

Foaming Properties: Can generate rich, stable foam even in hard water conditions, enhancing their use in cleaning products.

-

Emulsification: Efficient emulsifiers capable of forming both oil-in-water (O/W) and water-in-oil (W/O) emulsions, depending on the formulation and pH.

-

Compatibility: Because they have both anionic and cationic properties, they are compatible with other types of surfactants and can work synergistically to enhance cleaning effects.

-

Biodegradability: Many amphoteric surfactants are readily biodegradable, contributing to their environmentally friendly profile.

(High Quality Powder Flake Monochloroacetic Acid Flake Chloroacetic Acid)

Specification of High Quality Powder Flake Monochloroacetic Acid Flake Chloroacetic Acid

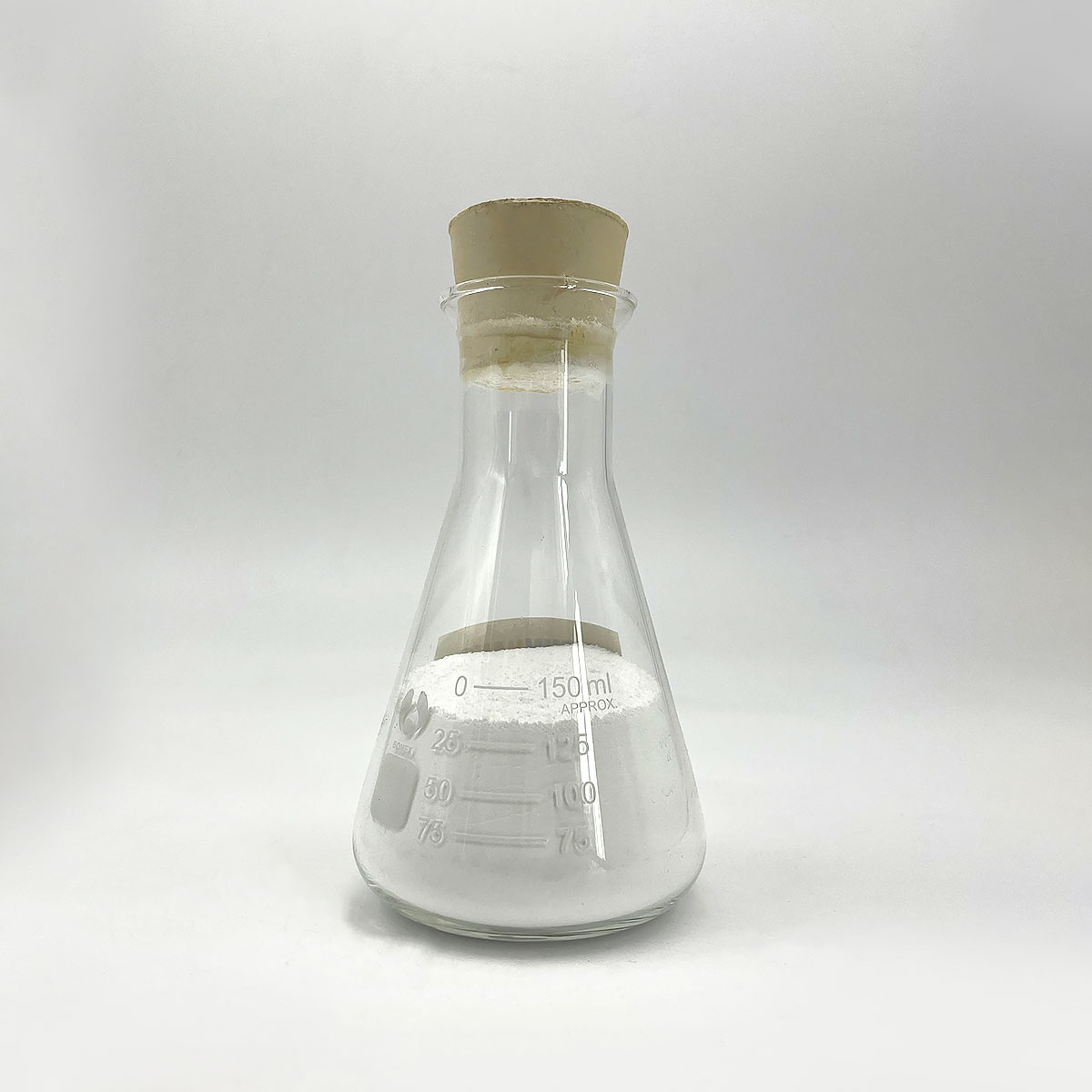

Excellent Quality Powder Flake Monochloroacetic Acid (MCAA) is a flexible chemical substance made use of in different sectors. The item appears as white crystalline flakes or powder. It has a chemical formula of C2H3ClO2 and a molecular weight of 94.49 g/mol. The purity level normally goes beyond 99%, making certain trusted performance in applications like pharmaceuticals, herbicides, and natural synthesis.

The material is steady under regular storage problems. It remains strong at area temperature level. The melting point ranges between 61-63 ° C. The boiling point is about 189 ° C. The compound liquifies quickly in water, ethanol, and other polar solvents. This solubility makes it ideal for liquid solutions.

Wetness content is purely regulated below 0.5% to stop clumping. The bit dimension distribution is uniform, with flakes gauging 2-5 mm in diameter. Powder variants have a great texture, passing through 80-mesh screens. This consistency guarantees even mixing in manufacturing procedures.

Product packaging alternatives include 25 kg polyethylene-lined bags or customized containers. The bags are secured to obstruct dampness and pollutants. Storage space referrals consist of cool, completely dry atmospheres far from direct sunlight. Appropriate handling stops destruction gradually.

Safety and security preventative measures are essential. The compound is corrosive and toxic if ingested or inhaled. Straight skin contact have to be stayed clear of. Personal protective equipment like gloves, goggles, and masks are compulsory throughout dealing with. Emergency procedures for spills include neutralization with alkaline substances.

Applications span several industries. In farming, it functions as a resources for herbicides like sodium chloroacetate. Pharmaceutical industries utilize it to manufacture medications, vitamins, and glycine. The chemical additionally acts as an intermediate in color production and carboxymethyl cellulose (CMC) production.

Quality assurance follows worldwide standards. Batch screening includes assays for purity, wetness, and hefty steel residues. Certificates of evaluation accompany each delivery. The production procedure makes use of advanced purification strategies to reduce impurities.

This product satisfies the demands of high-precision sectors. Its consistent top quality lowers handling mistakes. Producers rely upon it for reliable, scalable operations.

(High Quality Powder Flake Monochloroacetic Acid Flake Chloroacetic Acid)

Applications of High Quality Powder Flake Monochloroacetic Acid Flake Chloroacetic Acid

High-grade powder and flake monochloroacetic acid (MCAA), also known as chloroacetic acid, is a functional chemical compound used widely throughout industries. It works as a key active ingredient in natural synthesis. Producers rely upon it for creating carboxymethyl cellulose (CMC), a thickener located in food, pharmaceuticals, and paper products. The substance’s reactivity makes it suitable for customizing cellulose, enhancing texture and stability in these applications.

In drugs, MCAA is important for manufacturing active components. It assists create medicines like vitamins, anesthetics, and antiseptics. Its role in developing glycine by-products sustains the production of medications targeting metabolic disorders. The high purity of the powder or flake kind makes sure marginal pollutants, meeting strict pharmaceutical criteria.

The agriculture industry uses MCAA to manufacture herbicides. It works as a precursor for substances like 2,4-D and MCPA, which control broadleaf weeds in plants. These herbicides enhance crop returns by getting rid of competing plants. The fine powder or uniform flakes dissolve quickly, making sure reliable blending in formulas.

Textile sectors use MCAA to customize fibers. It helps in generating cellulose-based fabrics with improved dye absorption and sturdiness. This boosts material quality while reducing color waste. The substance’s stability under processing conditions makes it a reliable choice for industrial-scale operations.

MCAA also plays a role in water therapy. It aids synthesize coagulants that remove impurities from wastewater. These coagulants bind to pollutants, enabling less complicated filtration. The chemical’s efficiency supports cleaner water result in local and commercial therapy systems.

Personal treatment products like shampoos and lotions utilize MCAA-derived thickeners. These ingredients produce preferred textures without affecting item security. The substance’s compatibility with various other ingredients ensures smooth combination into formulas.

Suppliers prioritize high-purity MCAA powder and flakes for constant outcomes. Appropriate handling and storage space are essential due to the compound’s destructive nature. Industries worth its adaptability, driving need in global markets.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of High Quality Powder Flake Monochloroacetic Acid Flake Chloroacetic Acid

What is High Quality Powder Flake Monochloroacetic Acid?

High Quality Powder Flake Monochloroacetic Acid (MCAA) is a chemical compound used in industries like pharmaceuticals, agriculture, and chemical manufacturing. It comes in powder or flake forms. Both forms dissolve easily. They react well in processes requiring precise chemical reactions.

What industries use this product?

MCAA is common in making herbicides, carboxymethyl cellulose (CMC), and medicines. Factories use it to produce dyes, cosmetics, and surfactants. Its reactivity makes it useful for synthesizing other chemicals. Farmers rely on herbicides made with MCAA to protect crops.

Is Monochloroacetic Acid safe to handle?

MCAA is corrosive. Direct contact harms skin, eyes, and lungs. Workers must wear gloves, goggles, and masks. Proper ventilation is critical. Spills require immediate cleanup. Follow safety guidelines from suppliers or regulatory agencies. Store it away from incompatible materials like bases or oxidizers.

How should this product be stored?

Keep MCAA in a dry, cool place. Avoid moisture and high temperatures. Use airtight containers to prevent clumping or degradation. Do not store near food or beverages. Check containers regularly for leaks or damage. Follow local regulations for hazardous material storage.

What is the difference between powder and flake forms?

Powder dissolves faster in solutions needing quick reactions. Flakes are easier to handle in bulk processes. Both forms have the same chemical properties. Choose based on your equipment and production needs. Factories often prefer flakes for reduced dust. Labs might use powder for precise measurements.

Why does purity matter for this chemical?

Higher purity reduces impurities interfering with reactions. Industrial processes need consistent results. Lower purity grades risk unwanted byproducts. Always check the purity level matches your application. Most industries require at least 98% purity for reliable performance.

(High Quality Powder Flake Monochloroacetic Acid Flake Chloroacetic Acid)