Overview of High-Temperature Calcined Alumina Microspheres /Alumina Ball for Catalyst Carrier

Amphoteric surfactants are a unique class of surface-active agents that possess both cationic and anionic properties, depending on the pH of the system they are in. They contain both a positively charged group (like a quaternary ammonium salt) and a negatively charged group (such as a carboxylate or sulfonate), which can ionize depending on the surrounding conditions. This dual nature grants them exceptional versatility, making them effective in a wide range of pH environments and compatible with other surfactant types. They are known for their mildness and excellent dermatological compatibility, rendering them particularly suitable for personal care applications.

Features of High-Temperature Calcined Alumina Microspheres /Alumina Ball for Catalyst Carrier

-

pH Responsiveness: Their charge varies with pH, becoming cationic in acidic conditions and anionic in alkaline, with a zwitterionic (neutral) state at the isoelectric point.

-

Mildness: Known for being gentle on skin and eyes, making them ideal for sensitive applications like baby care and personal hygiene products.

-

Foaming Properties: Can generate rich, stable foam even in hard water conditions, enhancing their use in cleaning products.

-

Emulsification: Efficient emulsifiers capable of forming both oil-in-water (O/W) and water-in-oil (W/O) emulsions, depending on the formulation and pH.

-

Compatibility: Because they have both anionic and cationic properties, they are compatible with other types of surfactants and can work synergistically to enhance cleaning effects.

-

Biodegradability: Many amphoteric surfactants are readily biodegradable, contributing to their environmentally friendly profile.

(High-Temperature Calcined Alumina Microspheres /Alumina Ball for Catalyst Carrier)

Specification of High-Temperature Calcined Alumina Microspheres /Alumina Ball for Catalyst Carrier

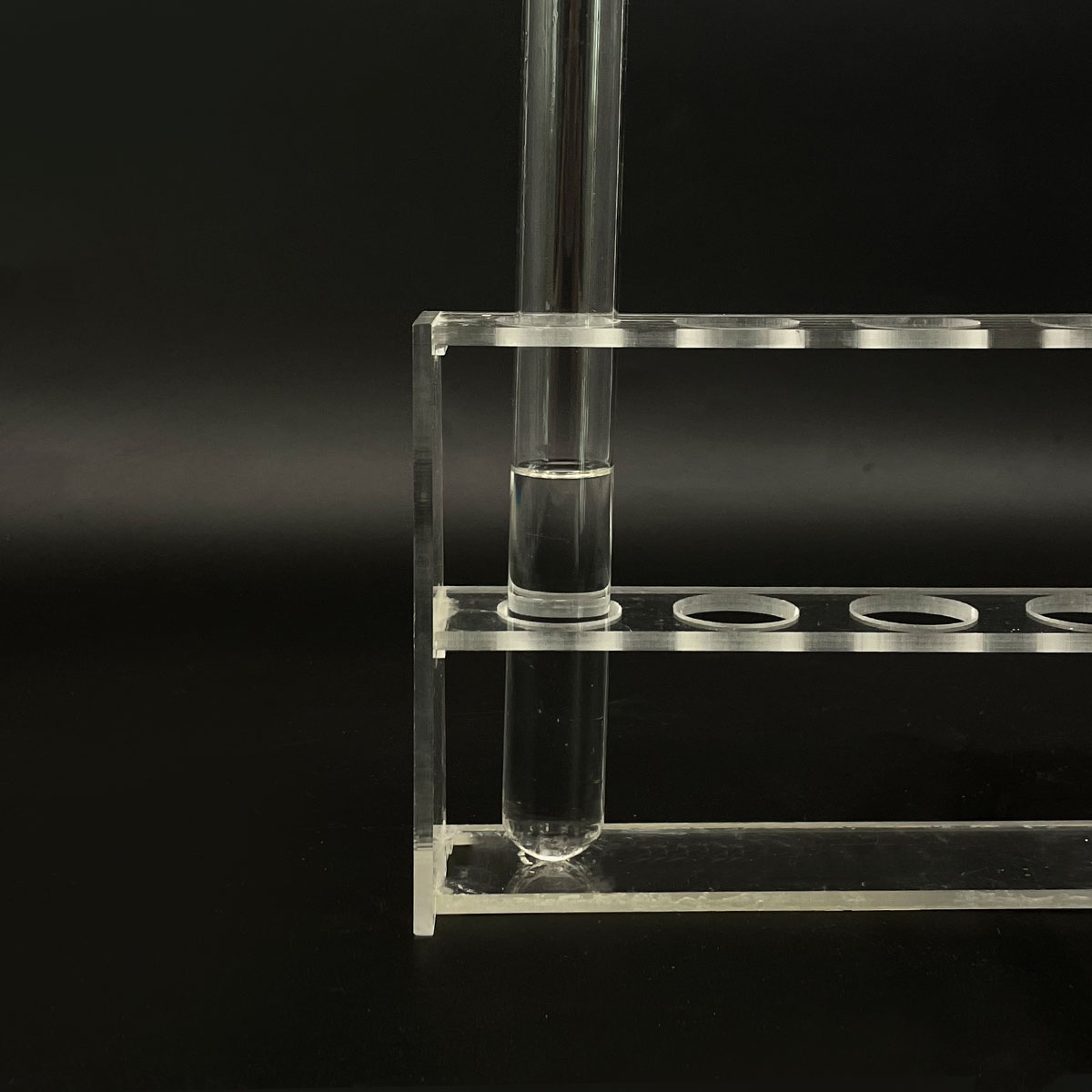

High-Temperature Calcined Alumina Microspheres, also called alumina spheres, work as catalyst service providers in commercial procedures. These products are made from high-purity aluminum oxide. They undergo calcination at severe temperatures, guaranteeing security under harsh conditions. The alumina material typically surpasses 99%, minimizing impurities that can disrupt catalytic reactions. The microspheres include an uniform round form, with diameters ranging from 1 mm to 10 mm. This uniformity allows even distribution in reactors, enhancing call in between drivers and reactants.

The product shows high mechanical stamina, standing up to crushing during managing or high-pressure procedures. Its porosity is flexible, tailored to particular catalytic demands. A controlled pore structure boosts area, advertising reliable stimulant loading. Thermal security is a key benefit. Alumina spheres withstand temperatures over 1600 ° C without warping or losing architectural honesty. This makes them ideal for procedures like hydrocarbon cracking or ammonia synthesis.

Chemical inertness is another important characteristic. The microspheres do not react with the majority of acids, alkalis, or natural solvents. They preserve efficiency in destructive environments, prolonging service life. Applications span sectors such as petroleum refining, chemical production, and environmental management. In refineries, they support stimulants for desulfurization or hydrogenation. In discharge control systems, they help break down toxins.

Manufacturing entails innovative sintering techniques, guaranteeing density and firmness satisfy commercial standards. The surface area is smooth, decreasing rubbing and use in fluidized beds. Custom sizes and pore circulations are offered for specialized usages. Storage space is straightforward. The material stays stable in moist or dry problems, avoiding deterioration with time.

Customers take advantage of reduced downtime due to the product’s resilience. Substitute cycles extend, decreasing upkeep expenses. Energy performance enhances due to the fact that the high thermal conductivity of alumina makes sure even heat transfer. This avoids locations in activators, maximizing reaction rates. Compatibility with different driver kinds includes flexibility. Industries rely on these microspheres for constant, dependable efficiency popular settings.

(High-Temperature Calcined Alumina Microspheres /Alumina Ball for Catalyst Carrier)

Applications of High-Temperature Calcined Alumina Microspheres /Alumina Ball for Catalyst Carrier

High-temperature calcined alumina microspheres, or alumina rounds, play a vital role as driver service providers in industrial processes. These materials hold up against extreme warm, withstand chemical corrosion, and keep architectural stability under harsh conditions. Their high surface and controlled porosity improve catalytic effectiveness by equally distributing energetic elements.

Alumina spheres are extensively used in petrochemical refining. They support catalysts in processes like hydrocracking and catalytic changing. The microspheres make certain also warm distribution, stop driver sintering, and expand life span. This minimizes downtime and functional prices in oil and gas processing.

Environmental applications take advantage of alumina balls. They act as carriers in automobile exhaust drivers, helping convert harmful gases like nitrogen oxides into harmless materials. Industrial emission control systems use them to eliminate toxins from manufacturing facility exhaust. The thermal stability of alumina makes sure constant performance in high-temperature flue gas settings.

Chemical synthesis relies on alumina spheres for ammonia and methanol manufacturing. They offer secure systems for catalysts in high-pressure reactors. The consistent pore structure of the microspheres enhances reactant circulation, increasing response rates and product purity. This is essential in generating bulk chemicals and fine pharmaceuticals.

Alumina balls serve in hydrogen production via heavy steam methane reforming. They support nickel-based drivers, guaranteeing reliable methane conversion. The product’s resistance to thermal shock prevents splitting throughout rapid temperature modifications. This improves hydrogen yield and procedure safety and security.

Refineries utilize alumina rounds in fluid catalytic cracking devices. They help damage down heavy hydrocarbons right into lighter gas like gas. The high mechanical strength of the microspheres minimizes wear in rough activator settings. This maintains stimulant activity and minimizes substitute frequency.

Alumina spheres are also applied in biomass conversion and syngas filtration. Their inert nature protects against undesirable side reactions. This makes sure tidy output in renewable resource processes. The flexibility of alumina microspheres across industries highlights their importance in modern-day catalytic systems.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of High-Temperature Calcined Alumina Microspheres /Alumina Ball for Catalyst Carrier

High-temperature calcined alumina microspheres are ceramic products made by processing alumina at extreme temperatures. They serve as catalyst carriers in industrial applications. Their uniform porous structure provides high surface area. This boosts catalyst efficiency. High purity ensures minimal contamination during chemical reactions. Thermal stability allows consistent performance under harsh conditions.

These alumina balls offer multiple benefits. High surface area supports better catalyst dispersion. Thermal stability prevents structural breakdown at elevated temperatures. Mechanical strength resists physical wear during handling. Chemical inertness avoids unwanted reactions with catalysts. These traits make them reliable in long-term operations. Maintenance costs drop due to durability.

They withstand temperatures up to 1600°C. The calcination process enhances their heat resistance. Crystal structure remains stable under prolonged exposure. This suits processes like hydrocarbon cracking. Thermal shock resistance prevents cracking during rapid temperature shifts. Performance stays reliable in fluctuating environments.

Common applications include petrochemical refining. They act as catalyst supports in hydrogen production. Environmental uses cover exhaust gas purification systems. Chemical synthesis relies on them for ammonia or methanol production. They function in fixed-bed reactors. High-temperature reactions benefit from their stability.

They differ from regular alumina in purity and structure. High-temperature calcination removes impurities. This creates a denser, more stable crystal lattice. Regular alumina lacks this heat-treated refinement. Standard alumina may degrade faster under stress. Microspheres have tailored porosity for catalyst needs. Regular versions suit less demanding roles like grinding media.

Proper handling extends their lifespan. Avoid mechanical impacts during installation. Clean surfaces prevent pore blockage. Monitor operating conditions to prevent overheating beyond limits. Regular inspections detect wear early. Replace damaged units promptly. Storage in dry conditions prevents moisture absorption. Follow manufacturer guidelines for optimal use.

(High-Temperature Calcined Alumina Microspheres /Alumina Ball for Catalyst Carrier)