Overview of High Viscosity Hydroxyl Terminated Pdms/107 Oh Polymer My 107

Polymer surfactants, also known as polymeric surfactants or amphiphilic polymers, are high-molecular-weight compounds that combine the properties of traditional low-molecular-weight surfactants with the unique features of polymers. Unlike small molecule surfactants, polymer surfactants offer enhanced stability, improved solubility, and the ability to form more complex structures such as micelles, hydrogels, and vesicles. These macromolecules find applications across a wide range of industries due to their tailored structures and tunable properties, which allow for precise control over interfacial behavior and solution rheology.

Features of High Viscosity Hydroxyl Terminated Pdms/107 Oh Polymer My 107

-

Molecular Weight and Structure: With a much higher molecular weight, polymer surfactants offer enhanced stability in harsh conditions and over prolonged periods compared to small molecule surfactants.

-

Tunability: The structure of polymer surfactants can be precisely engineered to include different functional groups, monomer sequences, and architectures, allowing for specific interactions and properties.

-

Multifunctionality: Apart from surface activity, they can also provide additional functionalities like thickening, rheology modification, and controlled release capabilities.

-

Self-Assembly: Capable of forming sophisticated self-assembled structures like micelles, hydrogels, and vesicles, which can encapsulate or release active ingredients in a controlled manner.

-

Environmental Compatibility: Many polymer surfactants are designed to be biodegradable and less toxic, making them suitable for eco-friendly applications.

-

Temperature and pH Responsiveness: Some polymer surfactants exhibit responsive behavior to changes in temperature or pH, enabling stimuli-responsive systems.

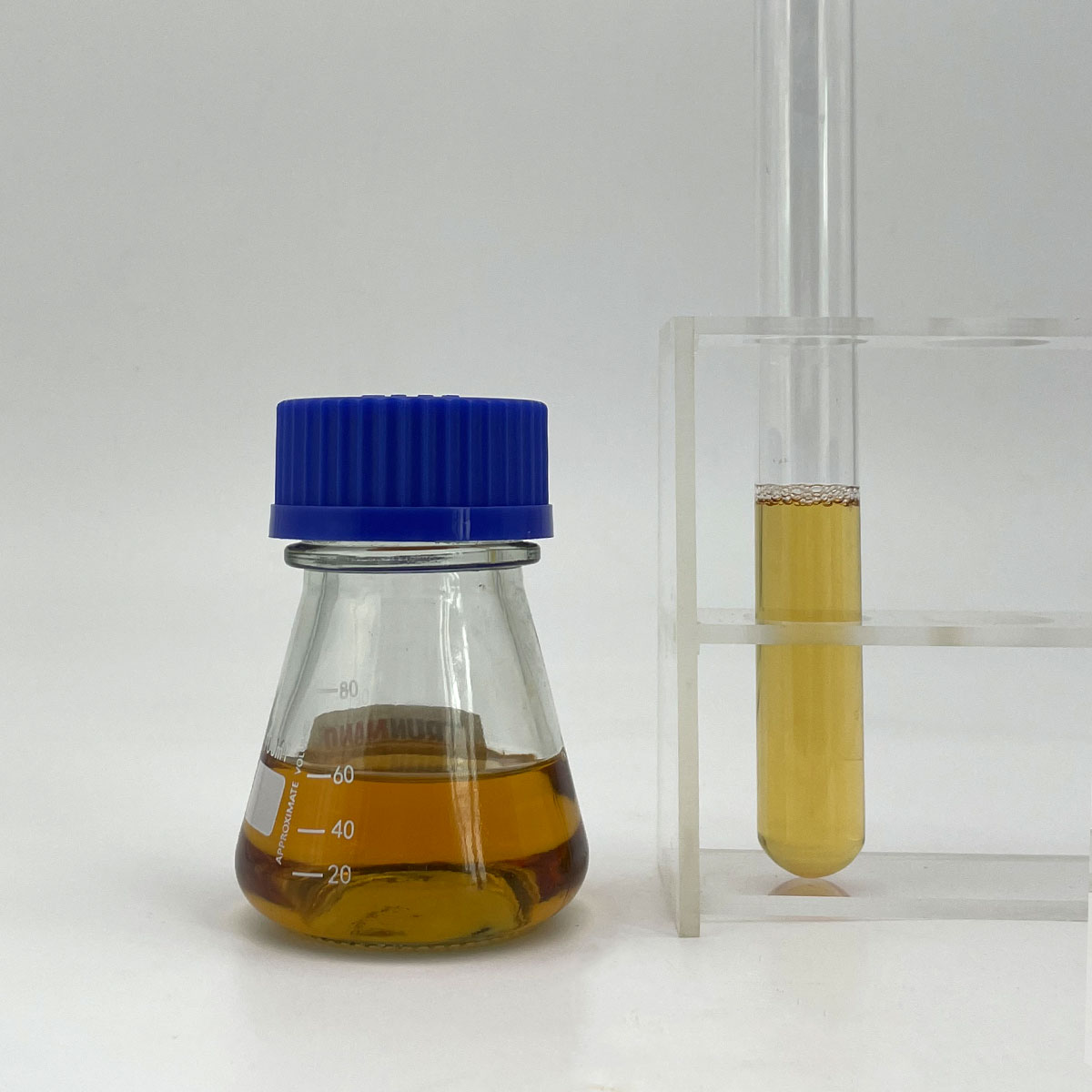

(High Viscosity Hydroxyl Terminated Pdms/107 Oh Polymer My 107)

Specification of High Viscosity Hydroxyl Terminated Pdms/107 Oh Polymer My 107

High Thickness Hydroxyl Terminated PDMS/107 OH Polymer MY 107 is a silicone-based product made for applications needing versatility, toughness, and resistance to extreme conditions. It has a hydroxyl-terminated framework, allowing strong bonding with surface areas and compatibility with ingredients. The polymer’s viscosity varies between 10,000 to 15,000 centipoise at 25 ° C, making it excellent for thick coverings or adhesives. Its molecular weight standards 107,000 g/mol, adding to mechanical stability under anxiety.

The hydroxyl web content is approximately 0.5% by weight, making sure reliable cross-linking throughout treating. This residential property improves attachment to substratums like metals, plastics, and ceramics. The material looks like a clear, colorless liquid with a density of 1.02 g/cm SIX. It stays pourable at area temperature level yet stands up to flow when applied, lessening dripping or sagging.

This polymer dissolves easily alike solvents such as toluene, xylene, and hexane. It resists wetness absorption, keeping performance in humid environments. Thermal security covers -50 ° C to 200 ° C, making it suitable for high-temperature applications. It keeps elasticity and resists breaking also after prolonged warmth direct exposure.

Applications consist of sealants, adhesives, and finishes in vehicle, aerospace, and electronics markets. It functions as a base for silicone rubber formulas, improving tear stamina and prolongation. The polymer is utilized in aesthetic products for its smooth texture and non-irritating buildings. It serves as a launch representative in molding procedures, stopping sticking without residue.

Storage calls for keeping the product in secured containers away from direct sunshine. Optimal storage temperature is in between 10 ° C and 30 ° C. Prolonged exposure to air should be prevented to avoid early healing. Blending with stimulants or cross-linkers speeds up curing time. Correct ventilation is suggested throughout handling.

The polymer satisfies industry requirements for safety and efficiency. It is free from damaging unstable organic substances (VOCs). Service life depends on 12 months when stored appropriately. Compatibility screening is encouraged for custom solutions. Technical support is readily available for certain application needs.

(High Viscosity Hydroxyl Terminated Pdms/107 Oh Polymer My 107)

Applications of High Viscosity Hydroxyl Terminated Pdms/107 Oh Polymer My 107

High Thickness Hydroxyl Ended PDMS/107 OH Polymer MY 107 is a silicone-based product recognized for its thick, steady structure and responsive hydroxyl teams. This polymer works well in sectors needing sturdy, adaptable, and heat-resistant solutions. Its high viscosity makes it suitable for applications where thickness and slow-moving flow issue.

In adhesives and sealants, MY 107 acts as a base material. It bonds highly to surfaces like steels, plastics, and glass. The hydroxyl groups assist it respond with various other chemicals, creating resilient seals immune to water, UV light, and severe temperature levels. This makes it helpful in building and construction for sealing windows or joints in high-stress environments.

Coatings and paints take advantage of MY 107’s capacity to create smooth, safety layers. It adds versatility to coatings, preventing splits when products expand or contract. Automotive parts, electronic gadgets, and commercial devices commonly use these finishes to stand up to wetness, chemicals, and wear.

Industrial producing relies upon MY 107 for mold and mildews and spreading. Its high thickness records great details without diminishing or deforming. This is important for producing accuracy components in aerospace, auto, or durable goods. The product stays steady under heat, making it ideal for processes entailing high temperatures.

Medical tools use MY 107 for its security and biocompatibility. It creates soft, adaptable parts like tubes or seals that call skin or bodily liquids. The polymer does not break down quickly, guaranteeing dependability in equipment like respirators or implants.

Electronics makers use MY 107 as an encapsulant or potting material. It shields sensitive parts from dust, wetness, and vibration. Its thermal security avoids overheating in tools like motherboard or sensing units.

MY 107 also shows up in individual care items. It offers lotions and creams a smooth appearance without feeling greasy. Its resistance to water aids products stay efficient in damp problems.

The polymer’s flexibility comes from its flexible residential properties. By customizing ingredients or processing approaches, makers tailor it for specific needs. This versatility maintains MY 107 appropriate throughout developing sectors.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of High Viscosity Hydroxyl Terminated Pdms/107 Oh Polymer My 107

High Viscosity Hydroxyl Terminated PDMS/107 OH Polymer MY 107 is a silicone-based material with high viscosity and reactive hydroxyl groups. It is used in coatings, adhesives, sealants, and medical devices. Below are answers to common questions.

What is High Viscosity Hydroxyl Terminated PDMS/107 OH Polymer MY 107?

This polymer is a silicone fluid with hydroxyl groups at both ends. Its high viscosity makes it ideal for creating durable, flexible products. It resists heat, water, and chemicals.

What industries use this polymer?

It is popular in automotive, electronics, healthcare, and construction. Manufacturers use it for lubricants, molds, waterproof coatings, and medical tubing. Its stability under extreme conditions suits demanding applications.

Why choose a high-viscosity grade?

Higher viscosity improves thickness and reduces flow in finished products. It enhances performance in coatings or adhesives needing strong adhesion. The material stays stable under stress or temperature changes.

Can it mix with other materials?

Yes. It blends with additives, resins, and fillers to modify properties. Testing compatibility first is recommended. Unmodified, it works well in silicone-based systems.

How should it be stored?

Keep it sealed in a cool, dry place away from moisture. Exposure to humidity causes premature reactions. Proper storage extends shelf life up to 12 months.

(High Viscosity Hydroxyl Terminated Pdms/107 Oh Polymer My 107)