Overview of Hydroxy Silicone Oil Oh Polymer Silicone Oil 10000cst 80000cst for Silicone Sealant CAS 70131-67-8

Polymer surfactants, also known as polymeric surfactants or amphiphilic polymers, are high-molecular-weight compounds that combine the properties of traditional low-molecular-weight surfactants with the unique features of polymers. Unlike small molecule surfactants, polymer surfactants offer enhanced stability, improved solubility, and the ability to form more complex structures such as micelles, hydrogels, and vesicles. These macromolecules find applications across a wide range of industries due to their tailored structures and tunable properties, which allow for precise control over interfacial behavior and solution rheology.

Features of Hydroxy Silicone Oil Oh Polymer Silicone Oil 10000cst 80000cst for Silicone Sealant CAS 70131-67-8

-

Molecular Weight and Structure: With a much higher molecular weight, polymer surfactants offer enhanced stability in harsh conditions and over prolonged periods compared to small molecule surfactants.

-

Tunability: The structure of polymer surfactants can be precisely engineered to include different functional groups, monomer sequences, and architectures, allowing for specific interactions and properties.

-

Multifunctionality: Apart from surface activity, they can also provide additional functionalities like thickening, rheology modification, and controlled release capabilities.

-

Self-Assembly: Capable of forming sophisticated self-assembled structures like micelles, hydrogels, and vesicles, which can encapsulate or release active ingredients in a controlled manner.

-

Environmental Compatibility: Many polymer surfactants are designed to be biodegradable and less toxic, making them suitable for eco-friendly applications.

-

Temperature and pH Responsiveness: Some polymer surfactants exhibit responsive behavior to changes in temperature or pH, enabling stimuli-responsive systems.

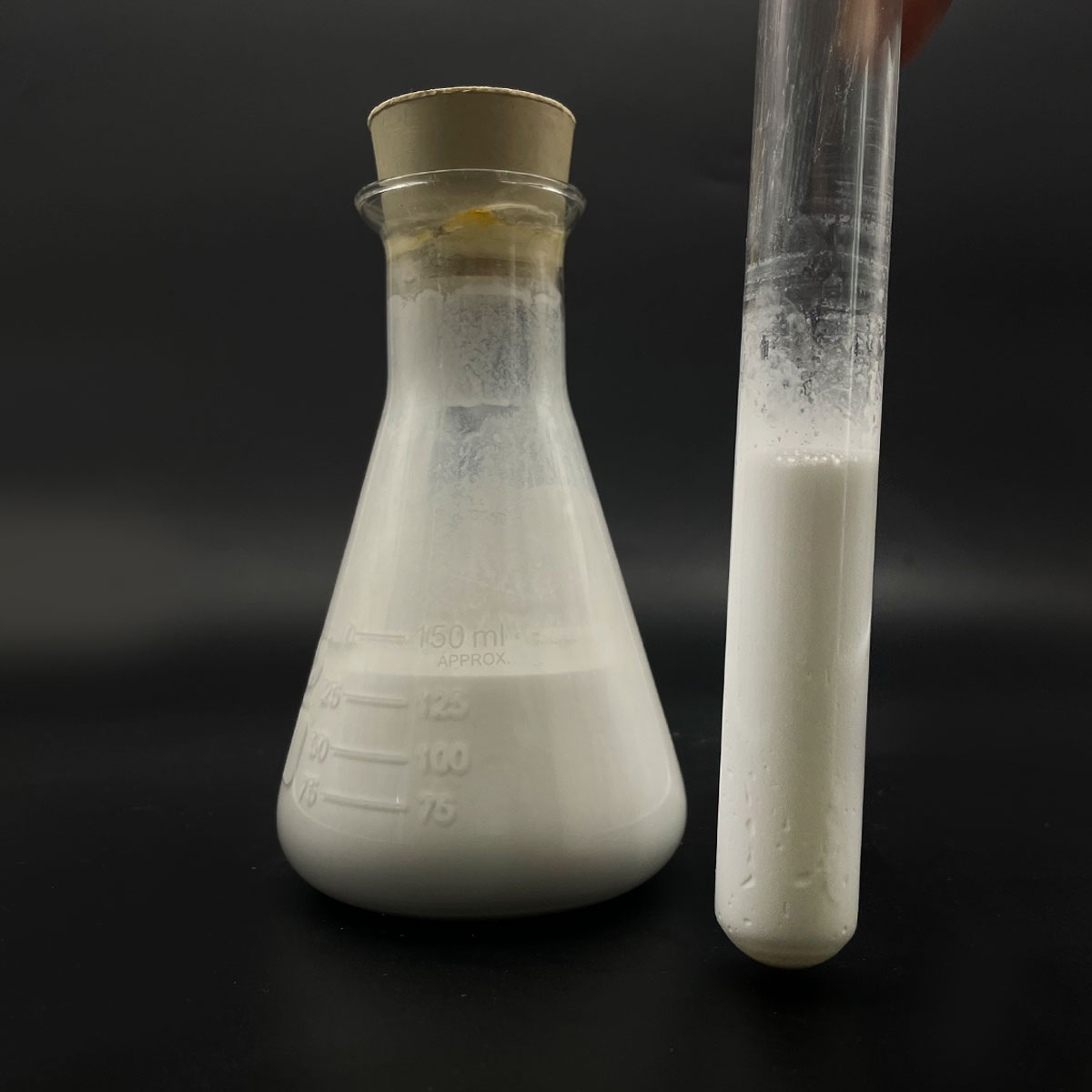

(Hydroxy Silicone Oil Oh Polymer Silicone Oil 10000cst 80000cst for Silicone Sealant CAS 70131-67-8)

Specification of Hydroxy Silicone Oil Oh Polymer Silicone Oil 10000cst 80000cst for Silicone Sealant CAS 70131-67-8

Hydroxy Silicone Oil OH Polymer Silicone Oil (CAS 70131-67-8) functions as a key element in silicone sealants and associated industrial applications. This item is readily available in high viscosities, consisting of 10000cst and 80000cst, developed to improve performance in solutions needing security and resilience. The product works as a responsive intermediate, enhancing versatility and adhesion in end products.

The hydroxy-functional silicone oil includes a clear, anemic appearance, guaranteeing it mixes effortlessly into clear or pigmented systems. Its hydroxyl groups make it possible for chain reactions with silanol-terminated polymers, creating solid networks in cured sealers. This results in enhanced mechanical buildings like tensile strength and elongation. The high viscosity qualities offer thickening effects, assisting in controlling circulation and droop throughout application.

Thermal security is an important benefit. The silicone oil endures temperature levels from -50 ° C to 200 ° C without derogatory, making it suitable for atmospheres revealed to heat or cold. Water resistance is an additional advantage, preventing wetness access and preserving seal integrity over time. Compatibility with usual ingredients like fillers, pigments, and crosslinkers makes certain adaptability throughout formulas.

Applications prolong past silicone sealants to adhesives, finishes, and rubber products. In building and construction, it boosts weatherproofing in joint sealers. Automotive and electronic devices industries utilize it for gaskets and potting compounds due to its dependability under tension.

Requirements consist of thickness series of 10000 ± 2000cst and 80000 ± 5000cst (25 ° C), hydroxyl web content in between 0.5% and 1.5%, and a density of roughly 0.97-0.98 g/cm TWO. The flash point surpasses 300 ° C, guaranteeing safety and security throughout high-temperature handling. The item is soluble in hydrocarbons, chlorinated solvents, and silicone liquids but insoluble in water or alcohols.

Storage space needs maintaining the oil in secured containers away from moisture and direct sunshine. Shelf life is commonly 12 months when kept listed below 30 ° C. Handling involves typical industrial safety and security techniques, including handwear covers and ventilation to prevent extended skin contact.

The hydroxy silicone oil fulfills sector requirements for top quality, making sure constant performance popular applications. Its duty in boosting item durability and capability makes it a recommended selection for manufacturers prioritizing reliability.

(Hydroxy Silicone Oil Oh Polymer Silicone Oil 10000cst 80000cst for Silicone Sealant CAS 70131-67-8)

Applications of Hydroxy Silicone Oil Oh Polymer Silicone Oil 10000cst 80000cst for Silicone Sealant CAS 70131-67-8

Hydroxy silicone oil OH polymer silicone oil (CAS 70131-67-8) is a versatile material utilized commonly in industrial and commercial items. The item can be found in various viscosities like 10000cst and 80000cst. These grades suit details requirements in production. The high thickness variations offer outstanding thickening effects. This makes them excellent for silicone sealers. Silicone sealants require steady, long lasting solutions. Hydroxy silicone oil boosts their efficiency. It helps sealers stand up to water, warm, and weather damages. Home builders use these sealants in construction for sealing windows, joints, and gaps. Automotive markets rely on them for engine components and gaskets. Electronic devices manufacturers apply silicone sealants with hydroxy silicone oil to safeguard circuits from moisture and dirt.

The oil’s structure permits it to blend well with various other silicone products. It keeps sealers adaptable even in severe temperatures. This avoids fracturing or reducing over time. The item is also utilized outside sealants. It functions as a lubricant in machinery needing high-temperature resistance. Some layers utilize it to add water-repellent properties. Individual care products like hair conditioners and skin creams include percentages for smooth textures.

Hydroxy silicone oil is simple to procedure. It mixes equally without clumping. Manufacturers conserve time and resources during production. The oil is risk-free to take care of under basic guidelines. It does not launch dangerous fumes during use. Ecological laws classify it as low-risk. This reduces disposal worries.

Industries select hydroxy silicone oil for its reliability. The 10000cst and 80000cst qualities meet stringent top quality criteria. They make sure consistent cause final products. Individuals benefit from enhanced longevity and efficiency. The oil’s versatility makes it a vital active ingredient across numerous fields. Its role in boosting silicone sealants remains vital for modern-day production demands.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Hydroxy Silicone Oil Oh Polymer Silicone Oil 10000cst 80000cst for Silicone Sealant CAS 70131-67-8

Hydroxy Silicone Oil Polymer (CAS 70131-67-8) is a silicone-based fluid with hydroxy groups. It is used in silicone sealants to improve flexibility, adhesion, and durability. Common viscosities include 10000cst and 80000cst. Below are answers to frequent questions.

What is Hydroxy Silicone Oil Polymer used for? This product acts as a key additive in silicone sealants. It enhances performance by adjusting viscosity, increasing weather resistance, and improving bonding strength. Industries like construction, automotive, and electronics rely on it for sealing joints, insulating components, and waterproofing.

How do 10000cst and 80000cst viscosities differ? The viscosity affects the sealant’s thickness and flow. 10000cst is thinner, ideal for applications needing smooth spreading. 80000cst is thicker, better for fillers requiring high strength. The choice depends on the sealant’s intended use.

Is this product safe to handle? Hydroxy Silicone Oil Polymer is non-toxic and stable under normal conditions. Wear gloves and goggles to avoid skin contact. Work in well-ventilated areas. Follow safety guidelines on the material’s SDS sheet.

Can it be mixed with other chemicals? Yes. It blends well with silicone resins, fillers, and catalysts. Test compatibility first. Small batches ensure no reactions affect the final product’s quality.

How should it be stored? Keep containers tightly sealed. Store in cool, dry places away from direct sunlight. Avoid moisture and high temperatures. Proper storage extends shelf life beyond 12 months. Check for clarity and viscosity changes before reuse.

These answers address basic concerns. For specific technical needs, consult product documentation or contact suppliers.

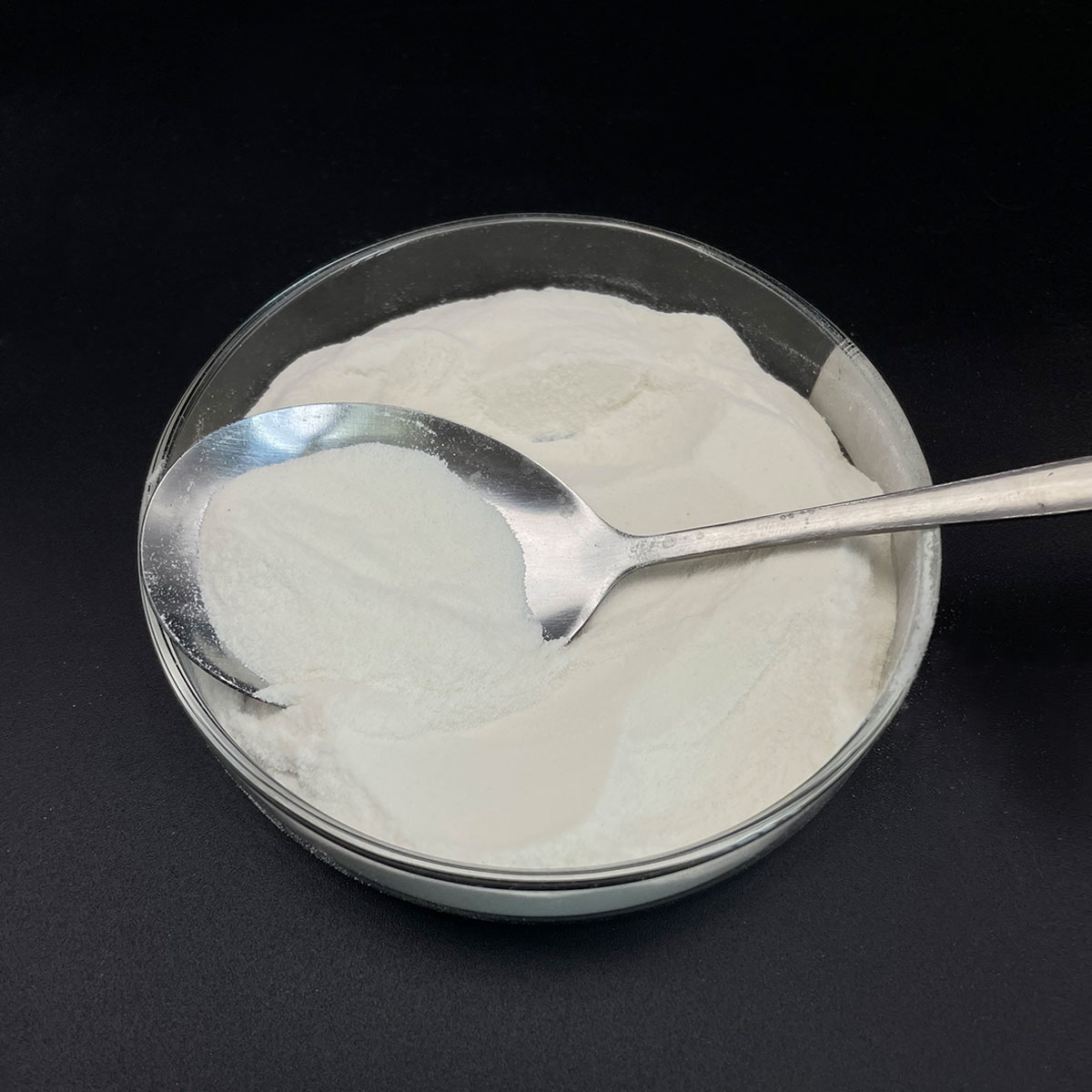

(Hydroxy Silicone Oil Oh Polymer Silicone Oil 10000cst 80000cst for Silicone Sealant CAS 70131-67-8)