Overview of Microsphere Alumina for Desiccant/Catalyst Carrier/Adsorbent, Large Pore Volume, Alumina Oxide, Activated Alumina, Calcined Alumina

Amphoteric surfactants are a unique class of surface-active agents that possess both cationic and anionic properties, depending on the pH of the system they are in. They contain both a positively charged group (like a quaternary ammonium salt) and a negatively charged group (such as a carboxylate or sulfonate), which can ionize depending on the surrounding conditions. This dual nature grants them exceptional versatility, making them effective in a wide range of pH environments and compatible with other surfactant types. They are known for their mildness and excellent dermatological compatibility, rendering them particularly suitable for personal care applications.

Features of Microsphere Alumina for Desiccant/Catalyst Carrier/Adsorbent, Large Pore Volume, Alumina Oxide, Activated Alumina, Calcined Alumina

-

pH Responsiveness: Their charge varies with pH, becoming cationic in acidic conditions and anionic in alkaline, with a zwitterionic (neutral) state at the isoelectric point.

-

Mildness: Known for being gentle on skin and eyes, making them ideal for sensitive applications like baby care and personal hygiene products.

-

Foaming Properties: Can generate rich, stable foam even in hard water conditions, enhancing their use in cleaning products.

-

Emulsification: Efficient emulsifiers capable of forming both oil-in-water (O/W) and water-in-oil (W/O) emulsions, depending on the formulation and pH.

-

Compatibility: Because they have both anionic and cationic properties, they are compatible with other types of surfactants and can work synergistically to enhance cleaning effects.

-

Biodegradability: Many amphoteric surfactants are readily biodegradable, contributing to their environmentally friendly profile.

(Microsphere Alumina for Desiccant/Catalyst Carrier/Adsorbent, Large Pore Volume, Alumina Oxide, Activated Alumina, Calcined Alumina)

Specification of Microsphere Alumina for Desiccant/Catalyst Carrier/Adsorbent, Large Pore Volume, Alumina Oxide, Activated Alumina, Calcined Alumina

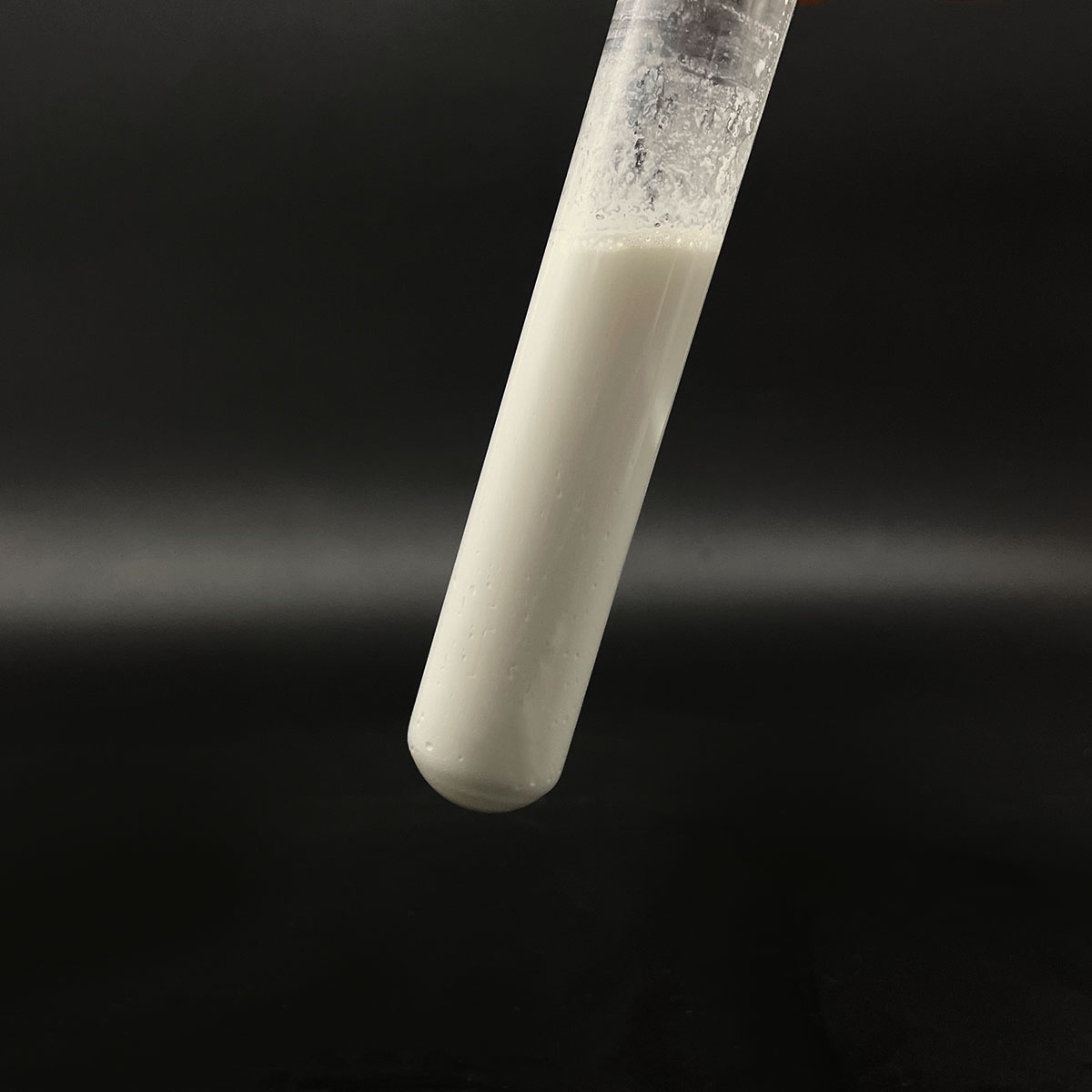

Microsphere alumina is a high-performance material designed for usage in desiccants, driver providers, and adsorbents. It is made from alumina oxide, processed to develop a structure with big pore quantity and high surface. This makes it very reliable for applications calling for wetness absorption, chemical reactions, or purification. The product is readily available in turned on and calcined kinds, each enhanced for details industrial needs.

The item features a porous framework with uniform particle distribution. This makes sure consistent efficiency popular settings. The huge pore volume enables fast adsorption and desorption of fluids or gases. It boosts performance in procedures like drying out air or gases, catalytic reactions, or removing contaminations from liquids. The high thermal stability of microsphere alumina allows use in high-temperature settings without architectural breakdown.

Activated alumina is frequently used as a desiccant because of its strong fondness for water particles. It can absorb dampness even at low humidity degrees. This makes it perfect for drying pressed air, gas, or refrigerants. In catalyst providers, the material supplies a secure base for energetic components. Its large surface area supports also dispersion of drivers, improving response prices and result.

Calcined alumina uses improved mechanical stamina and chemical inertness. It is matched for extreme problems where resilience matters. Applications include adsorbents in water therapy to eliminate hefty steels or fluoride. The material’s high pureness decreases contamination risks in delicate procedures.

Key specs consist of a surface of 200– 300 m TWO/ g, pore quantity of 0.6– 1.0 mL/g, and flexible particle dimensions from 1– 5 mm. The alumina content exceeds 99%, making sure marginal pollutants. It holds up against temperatures as much as 1000 ° C without destruction. Customizable choices are offered for pore size, density, and bit form to fulfill certain commercial requirements.

Microsphere alumina is widely used in petrochemical, environmental, and producing fields. Its flexibility and dependability make it a preferred option for optimizing procedures involving adsorption, catalysis, or wetness control. The material abides by sector standards for security and efficiency, making sure consistent lead to crucial applications.

(Microsphere Alumina for Desiccant/Catalyst Carrier/Adsorbent, Large Pore Volume, Alumina Oxide, Activated Alumina, Calcined Alumina)

Applications of Microsphere Alumina for Desiccant/Catalyst Carrier/Adsorbent, Large Pore Volume, Alumina Oxide, Activated Alumina, Calcined Alumina

Microsphere alumina is a high-performance material used in numerous commercial applications. Its distinct structure gives it a big pore volume. This makes it excellent for holding dampness, chemicals, or active compounds. Alumina oxide, the base part, is understood for its security and strength. Triggered alumina and calcined alumina are two typical kinds. Both are made by dealing with alumina under details conditions to increase their residential properties.

In desiccant applications, microsphere alumina works well since it soaks up water effectively. The big pore volume enables it to trap even more dampness than regular desiccants. This works in drying out gases or liquids. Industries like petrochemicals and air compression depend on it to keep systems completely dry. Triggered alumina is typically chosen right here since it can be restored easily. Heating it eliminates trapped water, so it can be recycled sometimes.

As a catalyst provider, microsphere alumina supplies a stable surface area for catalysts. The big pores let drivers spread evenly, boosting responses. Chemical plants utilize this in processes like refining or contamination control. Calcined alumina is preferred below. It takes care of high temperatures without breaking down. This guarantees the driver remains reliable also in extreme conditions.

For adsorption, microsphere alumina eliminates impurities from liquids or gases. Its high area grabs contaminants like hefty metals or natural compounds. Water treatment plants utilize it to clean drinking water. The huge pore volume suggests it can hold more pollutants prior to requiring substitute. Triggered alumina is common below since it operates in both acidic and neutral environments.

Microsphere alumina’s convenience comes from its adjustable buildings. Pore dimension and surface area can be tailored during production. This lets industries choose the right type for their demands. Alumina oxide’s all-natural resistance to warmth and chemicals includes in its dependability. Whether as a desiccant, catalyst carrier, or adsorbent, it offers consistent efficiency. Its function in improving effectiveness and lowering waste makes it a key material in contemporary sector.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Microsphere Alumina for Desiccant/Catalyst Carrier/Adsorbent, Large Pore Volume, Alumina Oxide, Activated Alumina, Calcined Alumina

Microsphere alumina is a specialized material used in industries needing high-performance desiccants, catalyst carriers, and adsorbents. Below are answers to common questions about its features and uses.

What is microsphere alumina?

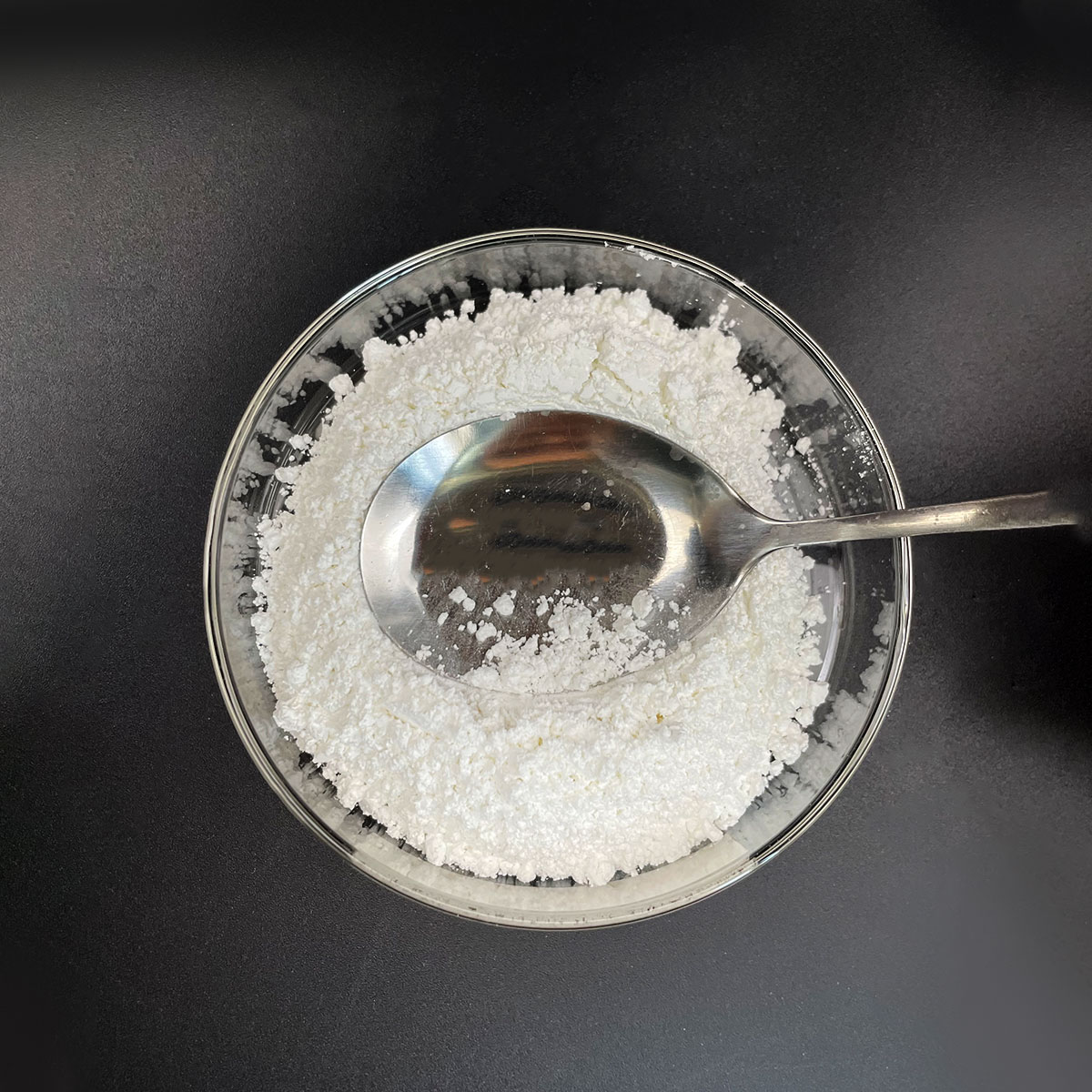

Microsphere alumina consists of small, spherical particles made from aluminum oxide. The material undergoes controlled processing to create uniform size and shape. This structure gives it high surface area and porosity, making it ideal for adsorption, catalysis, and drying applications.

Why use microsphere alumina as a desiccant?

Its large pore volume allows it to trap moisture efficiently. The pores absorb water vapor quickly, even in low-humidity environments. Unlike traditional desiccants, it maintains structural stability under repeated drying cycles. This reduces replacement frequency and lowers costs.

How does pore volume affect catalyst carrier performance?

Larger pores provide more space for catalytic substances to attach. This increases the catalyst’s active surface area, boosting reaction efficiency. The spherical shape ensures even distribution of catalysts, preventing clumping and improving process consistency.

What’s the difference between activated and calcined alumina?

Activated alumina is processed at lower temperatures, preserving more pores and surface area. It excels in adsorption tasks like water removal. Calcined alumina is heated at higher temperatures, reducing porosity but increasing hardness. It suits applications requiring thermal stability, like ceramic additives.

How should microsphere alumina be stored?

Keep it in a dry, sealed container to prevent moisture absorption before use. Avoid exposure to acids or strong alkalis, which can degrade its structure. Store it at room temperature, away from direct heat sources. Proper storage ensures long-term performance.

These answers clarify key aspects of microsphere alumina’s properties and handling. The material’s adaptability makes it valuable across industrial processes needing reliable moisture control, catalysis, or adsorption.

(Microsphere Alumina for Desiccant/Catalyst Carrier/Adsorbent, Large Pore Volume, Alumina Oxide, Activated Alumina, Calcined Alumina)