Overview of Nano Alumina Microsphere with Factory Catalyst Carrier

Amphoteric surfactants are a unique class of surface-active agents that possess both cationic and anionic properties, depending on the pH of the system they are in. They contain both a positively charged group (like a quaternary ammonium salt) and a negatively charged group (such as a carboxylate or sulfonate), which can ionize depending on the surrounding conditions. This dual nature grants them exceptional versatility, making them effective in a wide range of pH environments and compatible with other surfactant types. They are known for their mildness and excellent dermatological compatibility, rendering them particularly suitable for personal care applications.

Features of Nano Alumina Microsphere with Factory Catalyst Carrier

-

pH Responsiveness: Their charge varies with pH, becoming cationic in acidic conditions and anionic in alkaline, with a zwitterionic (neutral) state at the isoelectric point.

-

Mildness: Known for being gentle on skin and eyes, making them ideal for sensitive applications like baby care and personal hygiene products.

-

Foaming Properties: Can generate rich, stable foam even in hard water conditions, enhancing their use in cleaning products.

-

Emulsification: Efficient emulsifiers capable of forming both oil-in-water (O/W) and water-in-oil (W/O) emulsions, depending on the formulation and pH.

-

Compatibility: Because they have both anionic and cationic properties, they are compatible with other types of surfactants and can work synergistically to enhance cleaning effects.

-

Biodegradability: Many amphoteric surfactants are readily biodegradable, contributing to their environmentally friendly profile.

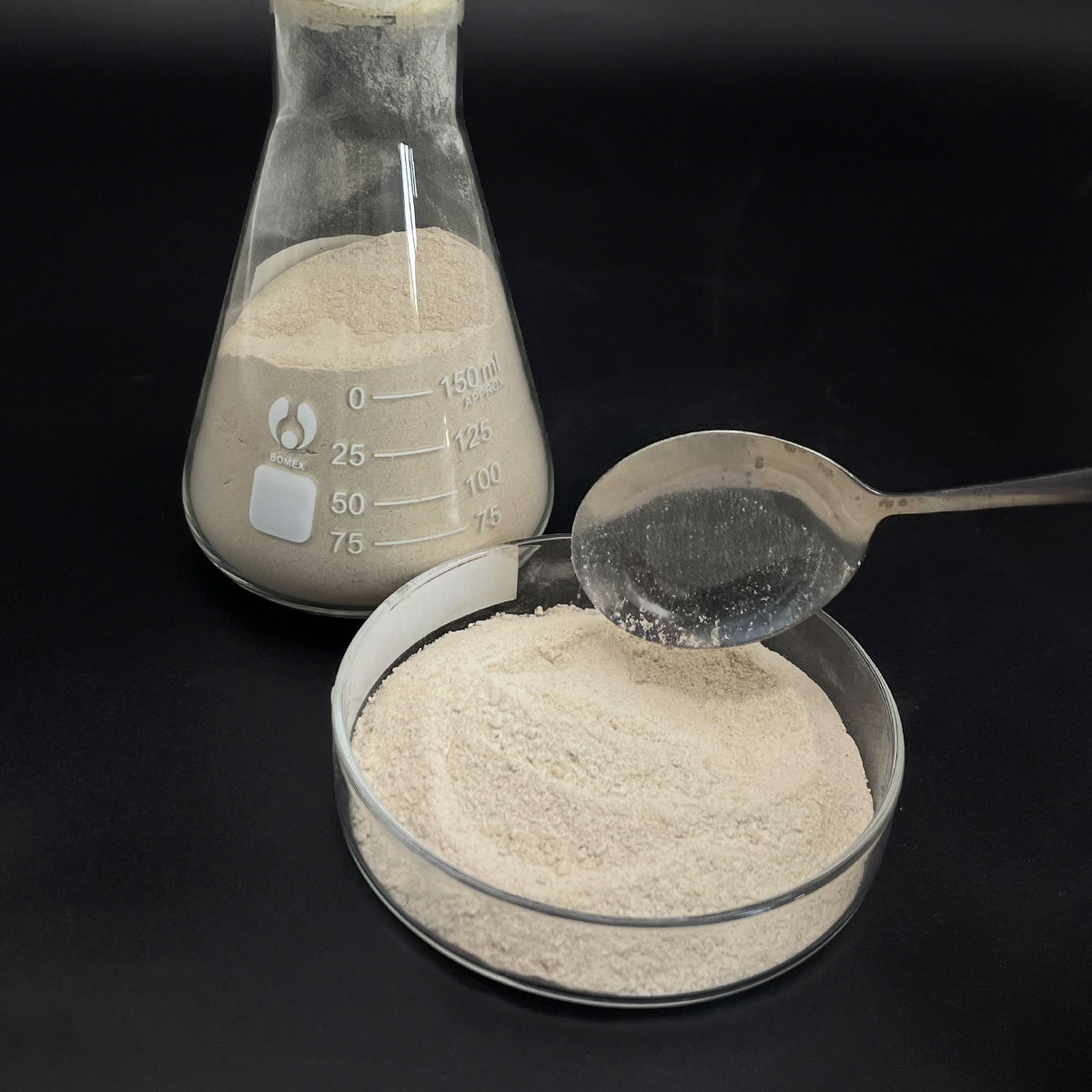

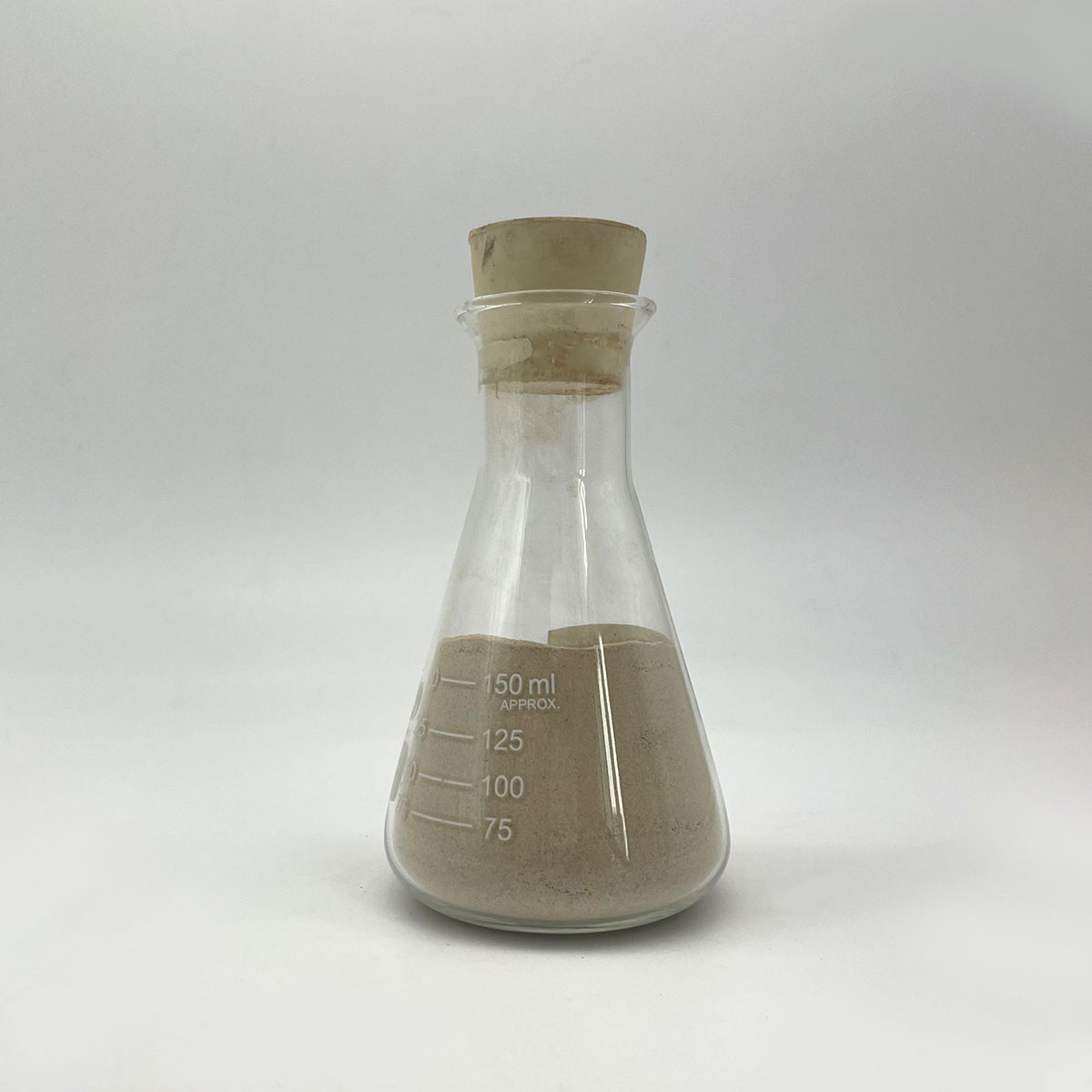

(Nano Alumina Microsphere with Factory Catalyst Carrier)

Specification of Nano Alumina Microsphere with Factory Catalyst Carrier

Nano Alumina Microsphere acts as a high-performance catalyst service provider designed for commercial applications. This product includes an exactly regulated particle dimension varying from 10 to 50 nanometers. The uniform spherical framework ensures also circulation of energetic catalytic components. A high surface area surpassing 200 m ²/ g boosts reaction efficiency by providing enough websites for chemical interactions.

The product exhibits extraordinary thermal stability, maintaining architectural honesty at temperatures as much as 1000 ° C. This residential property avoids deformation or collapse during high-heat procedures. Its chemical inertness withstands deterioration from acids, antacid, and natural solvents, guaranteeing long-term functionality in rough settings.

Pore framework is flexible in between 2 and 10 nanometers to accommodate diverse catalytic responses. This customization enables optimal mass transfer while preserving active compounds. The low mass density minimizes overall system weight, streamlining handling and integration into existing configurations.

Nano Alumina Microsphere supports applications in petrochemical refining, chemical synthesis, and environmental management systems. It boosts yield in hydrogenation, oxidation, and desulfurization processes. The item likewise helps in decreasing power intake by allowing reduced operating temperatures.

Production complies with strict top quality methods to ensure set consistency. Advanced techniques like sol-gel synthesis guarantee pureness degrees above 99.9%. Trace steel pollutants are maintained below 50 ppm to stay clear of catalytic poisoning.

The product’s mechanical stamina stands up to attrition during fluidized-bed operations. This toughness decreases fragment failure and extends life span. Cost-effectiveness stems from minimized catalyst substitute regularity and waste generation.

Packaging choices consist of moisture-proof secured bags or personalized containers for large orders. Technical assistance covers pore-size personalization, filling recommendations, and compatibility screening. The factory follows ISO standards, with third-party accreditations validating efficiency insurance claims.

Nano Alumina Microsphere adapts to both fixed-bed and fluidized-bed reactor layouts. Its flexibility addresses obstacles in gas-phase and liquid-phase reactions. Compatibility with rare-earth elements and transition metal oxides widens its applicability across markets.

(Nano Alumina Microsphere with Factory Catalyst Carrier)

Applications of Nano Alumina Microsphere with Factory Catalyst Carrier

Nano alumina microspheres act as essential materials in industrial catalyst carriers. Their small dimension and high area make them suitable for sustaining energetic catalytic components. Manufacturing facilities utilize these microspheres to enhance reaction effectiveness in chemical processes. The structure enables even circulation of catalysts, guaranteeing regular efficiency.

In the petrochemical market, nano alumina microspheres function as catalyst service providers for refining crude oil. They assist break down big hydrocarbon particles right into gas like fuel. The high thermal stability of alumina avoids catalyst deterioration under severe temperatures. This expands the life expectancy of stimulants, decreasing substitute prices.

Environmental applications consist of air and water filtration systems. Nano alumina microspheres assistance catalysts that transform unsafe toxins into much less poisonous materials. As an example, they enable factories to break down nitrogen oxides in exhaust gases. The permeable framework catches contaminants, boosting contact with catalytic agents.

Drug production relies upon these microspheres for manufacturing intricate medication compounds. Catalysts anchored on alumina surface areas speed up reactions without contamination. The uniform size of the microspheres makes certain precise control over reaction problems. This decreases by-products, improving item pureness.

Electronic devices manufacturing utilizes nano alumina microspheres to create sophisticated products. They function as carriers in processes like chemical vapor deposition. The high surface area supports slim, consistent finishes on digital parts. This boosts conductivity and durability in devices like semiconductors.

Nano alumina microspheres also contribute in hydrogen production. They support stimulants in steam changing responses, breaking water or methane right into hydrogen gas. The mechanical strength of alumina protects against service provider breakdown during high-pressure procedures. This makes certain constant hydrogen result for energy systems.

Factories pick nano alumina microspheres for their adaptability across sectors. The material’s inert nature stays clear of undesirable side reactions. Adjustable pore dimensions permit customizing to certain catalytic needs. This versatility makes them a conventional choice for maximizing commercial processes.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Nano Alumina Microsphere with Factory Catalyst Carrier

What are Nano Alumina Microspheres?

Nano alumina microspheres are tiny particles made from aluminum oxide. They have a high surface area and uniform pore structure. These features make them ideal for carrying catalysts in industrial processes. They help reactions happen faster and more efficiently.

Why use them as catalyst carriers?

Nano alumina microspheres handle high heat well. They resist chemical corrosion. Their porous structure lets catalysts spread evenly. This boosts contact between catalysts and reactants. Reactions become more stable and effective.

Where are they commonly applied?

They are used in oil refining, chemical production, and pollution control. Factories rely on them for processes like hydrogenation and oxidation. They also work in converting harmful gases into safer substances. Their durability suits harsh industrial environments.

How should they be stored and handled?

Keep them dry and away from moisture. Store them in sealed containers at room temperature. Avoid direct sunlight. Wear protective gear when handling to prevent inhaling particles. Follow factory guidelines for safe use.

Can they be customized for specific needs?

Yes. Factories adjust particle size, porosity, and surface chemistry based on client requirements. Custom designs improve performance in specialized reactions. Share your process details with suppliers to get the best fit.

The text avoids complex terms. It uses short sentences. Each answer directly addresses the question. Connections between ideas rely on clear cause-effect relationships. Technical details are simplified for easy understanding.

(Nano Alumina Microsphere with Factory Catalyst Carrier)