Overview of Non-Ionic Foam Control, Silicone Antifoam Agents

Specialty surfactants are a diverse class of surface-active agents designed for specific, high-performance applications where standard surfactants may not meet the required performance criteria. These surfactants are often tailor-made to exhibit unique properties, such as extreme temperature stability, low foam formation, high solubility in specific solvents, or compatibility with particular chemical systems. They are crucial components in formulations demanding precision, enhanced functionality, or strict regulatory compliance, found across industries from pharmaceuticals to advanced materials manufacturing.

Features of Non-Ionic Foam Control, Silicone Antifoam Agents

-

Customized Performance: Developed to meet exacting specifications, offering tailored functionalities beyond generic surfactants.

-

High Efficiency: Designed to work at lower concentrations or under challenging conditions, increasing performance per unit mass.

-

Unique Properties: May exhibit special traits such as non-flammability, low toxicity, high thermal stability, or specific solubility profiles.

-

Regulatory Compliance: Often formulated to meet stringent industry-specific regulations, such as food-grade, medical, or eco-friendly standards.

-

Innovative Chemistry: Incorporate novel chemistries, such as fluorinated, silicone-based, or bio-based structures, to achieve specialized performance.

-

Synergistic Effects: Frequently used in combination with other surfactants to enhance or augment performance in complex formulations.

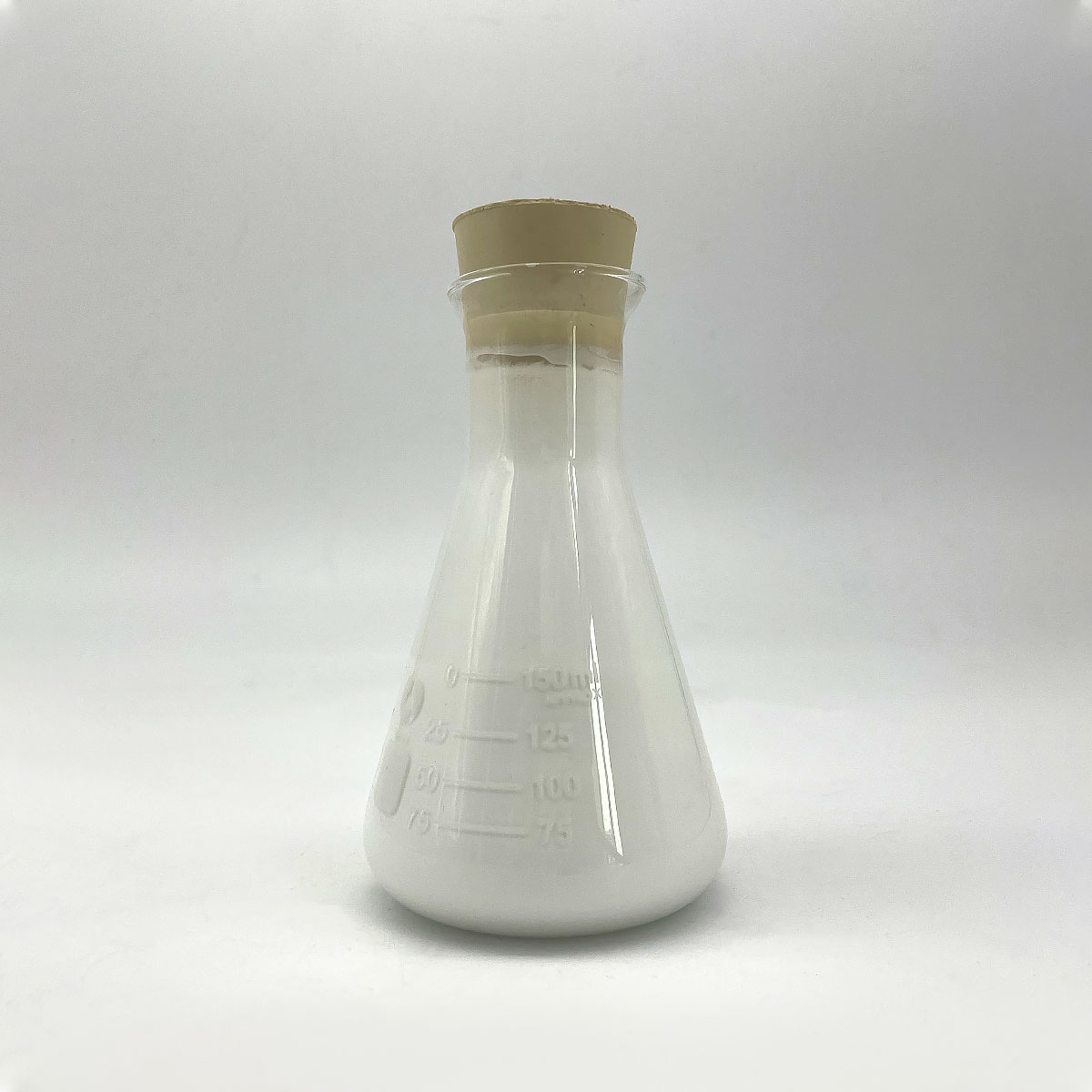

(Non-Ionic Foam Control, Silicone Antifoam Agents)

Specification of Non-Ionic Foam Control, Silicone Antifoam Agents

Non-ionic foam control silicone antifoam agents are created to take care of foam in commercial processes. These items incorporate silicone-based products with non-ionic surfactants. They function successfully across a wide range of temperature levels and pH degrees. The formulation ensures quick foam collapse while preventing new foam from forming. Compatibility with numerous systems is a crucial attribute. They do not react negatively with other chemicals in many configurations.

These antifoam representatives suit industries like wastewater therapy, food processing, and chemical production. They manage foam in upset fluids, fermentation containers, and high-temperature atmospheres. The non-ionic nature minimizes disturbance with ionic elements in the system. This makes them suitable for processes needing secure chemical balance.

The silicone element provides lasting foam suppression. Tiny silicone particles spread out evenly with the fluid. They break surface bubbles by reducing surface stress. The non-ionic surfactants aid spread silicone fragments without forming added foam. This dual-action approach ensures performance. Performance continues to be regular even under harsh conditions.

Individuals gain from reduced dose demands. Percentages provide solid defoaming impacts. This cuts expenses and decreases product deposit. The agents are safe and safe for use in controlled atmospheres. They meet standards for food-grade and pharmaceutical applications. No damaging results are released during foam control.

Application methods vary based upon the system. Direct enhancement to the liquid or splashing onto foam layers prevail. Examining is advised to identify optimum application points. The representatives incorporate smoothly into continual or batch procedures. Storage in great, dry conditions keeps product security. Life span normally surpasses one year if unopened.

Safety and security precautions include using gloves and eye protection throughout handling. Spills should be cleansed promptly to avoid unsafe surface areas. Appropriate air flow is recommended in encased areas. The representatives are non-flammable and position low environmental risk. Disposal adheres to typical guidelines for silicone-based products.

(Non-Ionic Foam Control, Silicone Antifoam Agents)

Applications of Non-Ionic Foam Control, Silicone Antifoam Agents

Non-ionic foam control representatives and silicone antifoam agents are widely made use of in sectors where foam causes operational problems. These products help in reducing or remove foam without affecting procedure efficiency. Non-ionic representatives function by breaking foam bubbles through surface area stress decrease. They are steady in numerous temperature levels and pH degrees. This makes them ideal for applications requiring compatibility with other chemicals.

In wastewater therapy, foam can interfere with oygenation and slow-moving processing. Non-ionic foam control agents are included in stop excess foam. They blend well with organic products and do not interfere with organic treatments. Silicone antifoams are additionally reliable below. They work promptly and require reduced does.

Food and beverage production often deals with foam problems during mixing or loading. Non-ionic representatives are safe for usage right here. They do not leave dangerous deposits. Silicone antifoams are used in fermentation procedures. They handle heats and acidic conditions.

Chemical producing uses these representatives to manage foam in reactors and purification. Foam can cause spills or inaccurate measurements. Non-ionic items give steady performance in hostile chemical environments. Silicone choices offer durable foam suppression.

Drug manufacturing relies on foam control for constant product quality. Non-ionic representatives are liked for their pureness. They fulfill stringent regulatory requirements. Silicone antifoams protect against foam throughout medication synthesis. They do well in high-shear mixing.

Pulp and paper mills utilize these agents to manage foam in cleaning and bleaching. Foam minimizes devices performance. Non-ionic representatives break foam without influencing paper quality. Silicone antifoams deal with large systems effectively.

Farming uses foam control in pesticide and fertilizer production. Foam can cause irregular coating or packaging issues. Non-ionic agents make certain smooth processing. Silicone antifoams are made use of in spray remedies. They protect against blocking and improve protection.

These agents are crucial in paints and finishes. Foam develops defects during application. Non-ionic representatives keep product consistency. Silicone antifoams operate in water-based and solvent-based formulas.

Oil and gas sectors use foam control in boring and refining. Foam decreases processes and threats security. Non-ionic agents manage high-pressure conditions. Silicone antifoams handle foam in petroleum separation.

Textile producing uses these agents to avoid foam in coloring and completing. Foam leads to uneven color distribution. Non-ionic agents work with dyes. Silicone antifoams make certain smooth material handling.

The adaptability of non-ionic and silicone antifoam representatives makes them vital across fields. They improve safety and security, performance, and item high quality.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Non-Ionic Foam Control, Silicone Antifoam Agents

Non-ionic foam control agents and silicone antifoam agents stop foam from forming in industrial processes. They break bubbles quickly and prevent new ones. These products suit many industries.

1. What are non-ionic foam control agents and silicone antifoams?

Non-ionic foam control agents are chemicals without electrical charge. They work in many conditions. Silicone antifoams use silicone-based materials. Both reduce foam in liquids. They are stable in high temperatures and different pH levels.

2. How do these agents stop foam?

They spread on foam surfaces. This breaks bubble walls. Surface tension drops. Bubbles collapse. The process is fast. It stops foam from reforming. Silicone antifoams work in small doses. Non-ionic agents handle harsh environments better.

3. Where are these antifoam agents used?

Factories use them in wastewater treatment. Food processing plants apply them during production. Pharmaceuticals rely on them for drug manufacturing. They work in chemical processing and fermentation. Any industry with liquid foam issues benefits.

4. Why pick non-ionic or silicone agents over ionic types?

Non-ionic agents avoid reactions with charged substances. They stay effective in acidic or alkaline conditions. Silicone antifoams last longer. They need less product. Ionic agents might interfere with other chemicals. Non-ionic and silicone options are more versatile.

5. Are these agents safe for the environment?

Most meet environmental standards. They are non-toxic in recommended doses. Some silicone antifoams degrade slowly. Check local rules before use. Non-ionic agents often break down faster. Always follow disposal guidelines.

(Non-Ionic Foam Control, Silicone Antifoam Agents)