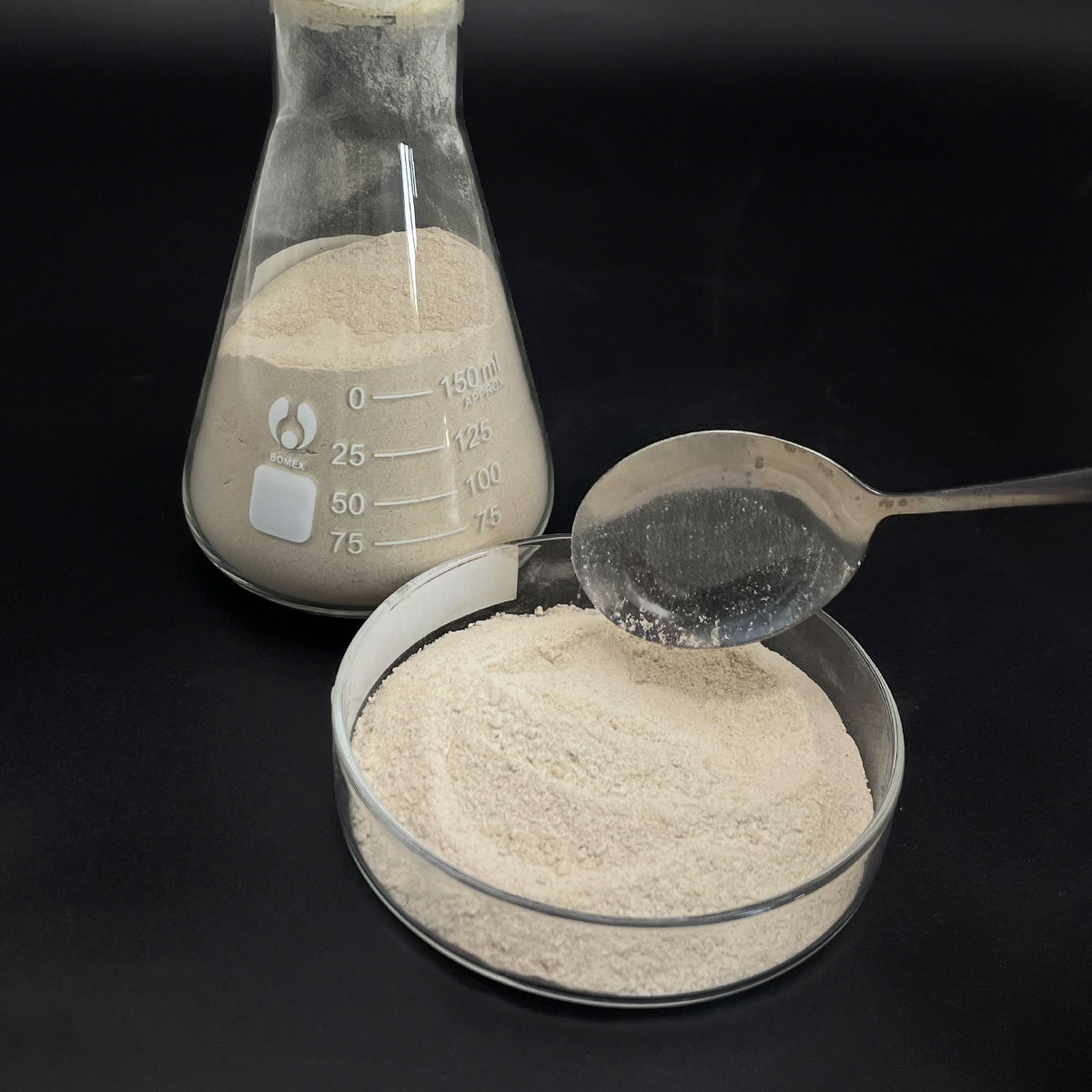

Overview of Pesticide Emulsifier; Mixed Pesticide Emulsifiers; Nonionic/Anionic Surfactants

Anionic surfactants are a class of surface-active agents characterized by a negatively charged hydrophilic head group when dissolved in water. This charge arises from the presence of a sulfate, sulfonate, phosphate, or carboxylate group. They are among the most widely used surfactants due to their effective cleaning properties, foaming capacity, and broad compatibility with other formulation ingredients. Anionic surfactants find extensive application across industries, including personal care, household cleaning, textiles, and industrial processes.

Features of Pesticide Emulsifier; Mixed Pesticide Emulsifiers; Nonionic/Anionic Surfactants

-

Negative Charge: The anionic head group imparts water solubility and enables interaction with positively charged surfaces or particles.

-

Detergency: Exceptional at removing dirt, grease, and oils due to their strong polarity and ability to penetrate and disrupt these substances.

-

Foaming Properties: Many anionic surfactants generate stable and abundant foam, making them ideal for applications where lather is desired.

-

Cost-Effectiveness: They are often less expensive than nonionic, cationic, or amphoteric surfactants due to the abundance of raw materials and established production processes.

-

Compatibility: Can be combined with other surfactants to enhance performance or adjust properties, although care must be taken to avoid precipitation or incompatibility issues.

-

Environmental Considerations: Some anionic surfactants may pose environmental concerns due to their persistence or toxicity; however, biodegradable options are available.

(Pesticide Emulsifier; Mixed Pesticide Emulsifiers; Nonionic/Anionic Surfactants)

Specification of Pesticide Emulsifier; Mixed Pesticide Emulsifiers; Nonionic/Anionic Surfactants

Chemical emulsifiers blend oil-based pesticides with water. They create secure spray mixes. This ensures also chemical coverage on crops. Blended pesticide emulsifiers combine different surfactant types. They provide better performance than solitary surfactants. Nonionic surfactants have no electric charge. They take care of water firmness well. Anionic surfactants bring a negative cost. They offer solid emulsifying power. Incorporating nonionic and anionic surfactants is common. This blend utilizes the staminas of both kinds.

Nonionic surfactants improve solubility. They aid the blend spread on leaves. Anionic surfactants increase solution security. They prevent the oil and water from separating swiftly. With each other, they produce an even more robust solution. This combination functions across various water high qualities. It performs well with numerous chemical formulations.

These mixed emulsifiers fit many chemical kinds. They deal with insecticides, herbicides, and fungicides. Farmers obtain reputable combinations. This causes regular chemical application. Plant security enhances. Sprayer nozzles block much less often. Container mixes stay consistent much longer. Customers see fewer application problems. Efficiency is dependable under various problems.

The blend offers formulation adaptability. Makers readjust the nonionic/anionic proportion. This tailors the emulsifier for certain chemical oils. It maximizes price and effectiveness. Manufacturing procedures stay reliable. End-users take advantage of easier handling. Chemical efficiency meets assumptions. Security during storage space is excellent. Life span continues to be long.

(Pesticide Emulsifier; Mixed Pesticide Emulsifiers; Nonionic/Anionic Surfactants)

Applications of Pesticide Emulsifier; Mixed Pesticide Emulsifiers; Nonionic/Anionic Surfactants

Pesticide emulsifiers make oil-based pesticides blend correctly with water. Farmers need this. Great mixing suggests the pesticide spreads out uniformly on crops. This provides much better parasite control. It stops the spray from obstructing nozzles. It likewise protects against the pesticide from dividing in the storage tank. Splitting up wastes item and causes uneven application.

Mixed pesticide emulsifiers integrate different kinds of emulsifiers. This method prevails. It takes on hard blending tasks far better than a single emulsifier. Some pesticide formulas are difficult to mix with water. Combined emulsifiers take care of these challenging blends reliably. They provide versatility. Formulators can change the blend for various chemical oils. This develops a secure solution whenever. Stability is vital for reliable spraying.

Nonionic and anionic surfactants are core components in these emulsifiers. Each kind functions differently. Nonionic surfactants are not billed. They are normally mild. They work well in numerous water problems, difficult or soft. Anionic surfactants lug a negative cost. They supply strong emulsifying power. Incorporating nonionic and anionic surfactants leverages both staminas. The mix increases overall performance. It makes certain the solution remains steady. It aids the chemical stick to plant surfaces. It boosts the spray’s insurance coverage and penetration. This combination is commonly one of the most cost-effective option. It supplies dependable results for lots of pesticide applications. Using the appropriate emulsifier blend saves time and money. It takes full advantage of the chemical’s performance in the field.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Pesticide Emulsifier; Mixed Pesticide Emulsifiers; Nonionic/Anionic Surfactants

What are mixed pesticide emulsifiers?

These are blends of nonionic and anionic surfactants. They help mix oil-based pesticides with water. This creates a stable emulsion spray. Farmers need this for effective pest control.

Why use mixed emulsifiers instead of single types?

Mixed types work better. They offer stronger emulsifying power. They handle different water qualities well. They are more stable across various temperatures. Single types often struggle with these factors. Water quality matters a lot in the field.

How do I choose the right emulsifier ratio?

The best ratio depends on the pesticide concentrate. It also depends on the water hardness where you spray. Manufacturers provide guidelines. Follow them. Test small batches first. Adjust if the emulsion breaks or separates.

What’s the big advantage of nonionic/anionic blends?

They are very versatile. These blends emulsify many pesticide formulations. They work in hard or soft water. They perform at different temperatures. You get reliable mixing. This reduces application problems. Spray coverage improves.

Are these emulsifiers safe to handle?

Handle them with care. Always read the product safety sheet. Wear proper protective gear. This means gloves, goggles, and sometimes a mask. Avoid skin contact. Avoid breathing mist. Store them correctly away from food and kids.

(Pesticide Emulsifier; Mixed Pesticide Emulsifiers; Nonionic/Anionic Surfactants)