Overview of Polymer Polyol Pop 10% 13% 15% 25% 45% for Sponge Foaming Mattress

Polymer surfactants, also known as polymeric surfactants or amphiphilic polymers, are high-molecular-weight compounds that combine the properties of traditional low-molecular-weight surfactants with the unique features of polymers. Unlike small molecule surfactants, polymer surfactants offer enhanced stability, improved solubility, and the ability to form more complex structures such as micelles, hydrogels, and vesicles. These macromolecules find applications across a wide range of industries due to their tailored structures and tunable properties, which allow for precise control over interfacial behavior and solution rheology.

Features of Polymer Polyol Pop 10% 13% 15% 25% 45% for Sponge Foaming Mattress

-

Molecular Weight and Structure: With a much higher molecular weight, polymer surfactants offer enhanced stability in harsh conditions and over prolonged periods compared to small molecule surfactants.

-

Tunability: The structure of polymer surfactants can be precisely engineered to include different functional groups, monomer sequences, and architectures, allowing for specific interactions and properties.

-

Multifunctionality: Apart from surface activity, they can also provide additional functionalities like thickening, rheology modification, and controlled release capabilities.

-

Self-Assembly: Capable of forming sophisticated self-assembled structures like micelles, hydrogels, and vesicles, which can encapsulate or release active ingredients in a controlled manner.

-

Environmental Compatibility: Many polymer surfactants are designed to be biodegradable and less toxic, making them suitable for eco-friendly applications.

-

Temperature and pH Responsiveness: Some polymer surfactants exhibit responsive behavior to changes in temperature or pH, enabling stimuli-responsive systems.

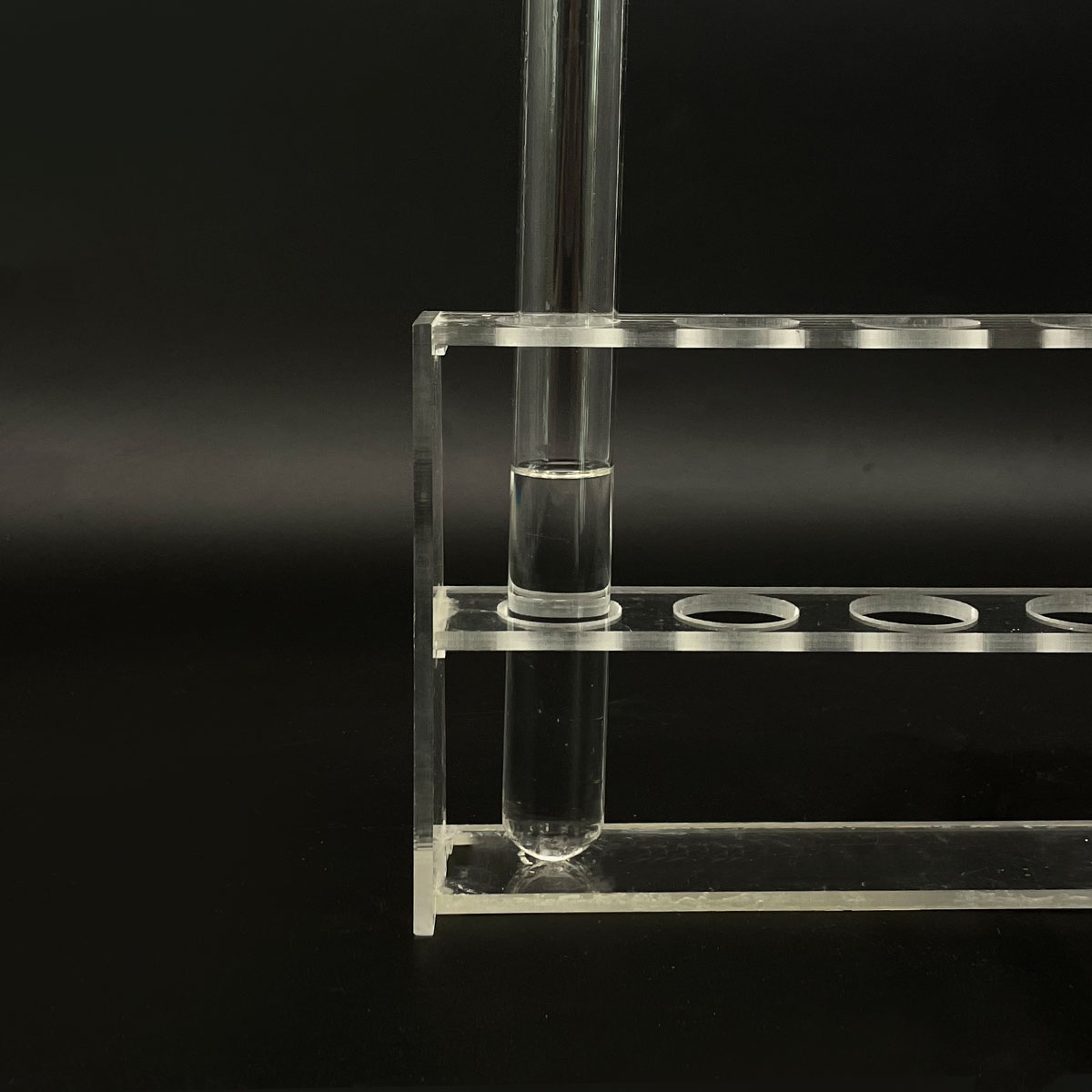

(Polymer Polyol Pop 10% 13% 15% 25% 45% for Sponge Foaming Mattress)

Specification of Polymer Polyol Pop 10% 13% 15% 25% 45% for Sponge Foaming Mattress

Polymer Polyol Pop is a key material used in sponge foaming for mattress production. It comes in concentrations of 10%, 13%, 15%, 25%, and 45% to meet different performance needs. The product enhances foam structure by improving elasticity and durability. Higher polymer content increases firmness and support. Lower percentages create softer, more flexible foams.

This material works with polyurethane systems to produce high-resilience sponge mattresses. The polymer particles strengthen foam cells during the foaming process. This results in mattresses that retain shape over time. The 10% and 13% options suit lightweight designs for medium softness. The 15% variant balances comfort and support for everyday use.

Higher concentrations like 25% and 45% deliver firm structures ideal for heavy-duty applications. These grades improve load-bearing capacity. They prevent sagging in mattresses used frequently. The polymer content also boosts resistance to wear and compression. Mattresses stay comfortable longer without losing performance.

Polymer Polyol Pop ensures consistent cell formation during production. It mixes well with other polyols, isocyanates, and additives. The material maintains stable reactivity for controlled foaming. Processing temperatures range between 20°C and 35°C for optimal results. Mixing ratios vary based on desired foam density.

The product meets safety standards for mattress manufacturing. It has low volatile organic compound (VOC) emissions. This makes it suitable for eco-friendly production. Foams made with Polymer Polyol Pop pass flammability and durability tests. They comply with industry regulations for residential and commercial use.

Customization is possible by adjusting the polymer percentage. Lower concentrations reduce material costs while maintaining quality. Higher levels enhance premium features like orthopedic support. Manufacturers choose grades based on mattress thickness, density, and target market needs.

Processing methods include manual pouring or automated systems. Cure times depend on catalyst levels and ambient conditions. Finished foams exhibit fine, uniform cell structures. They provide balanced airflow for temperature regulation. Mattresses stay cool and comfortable during sleep.

Applications extend beyond home mattresses to furniture cushions and automotive seating. Medical foam products also use this material for pressure relief. The versatility of Polymer Polyol Pop makes it a reliable choice for diverse foaming requirements.

(Polymer Polyol Pop 10% 13% 15% 25% 45% for Sponge Foaming Mattress)

Applications of Polymer Polyol Pop 10% 13% 15% 25% 45% for Sponge Foaming Mattress

Polymer polyol POP with concentrations like 10%, 13%, 15%, 25%, and 45% is widely used in sponge foaming for mattresses. This material improves foam structure by adding flexibility and strength. Different percentages serve different purposes based on the desired mattress properties. Lower concentrations like 10% or 13% create softer foams suitable for comfort layers. These foams adapt to body shapes, providing pressure relief for better sleep quality. Higher concentrations like 25% or 45% produce firmer foams ideal for support layers. These foams maintain shape over time, preventing sagging and extending mattress lifespan.

The 15% concentration balances softness and support, often used in middle layers. It ensures even weight distribution while keeping the surface comfortable. Polymer polyol POP enhances foam durability by resisting wear and tear. It also improves airflow within the foam, reducing heat buildup during sleep. This material is cost-effective for manufacturers. It reduces raw material use without sacrificing performance.

Polymer polyol POP allows precise control over foam density. Manufacturers adjust the percentage to meet specific firmness requirements. This flexibility supports custom mattress designs for different user needs. The chemical structure of polymer polyol POP promotes uniform cell formation during foaming. Consistent cell size improves comfort by minimizing pressure points.

Mattresses made with polymer polyol POP are lightweight yet sturdy. They are easier to handle during production and shipping. The material’s stability during processing reduces defects, lowering waste. It works well with other foam additives, enabling advanced features like moisture resistance or flame retardancy.

Polymer polyol POP contributes to eco-friendly manufacturing. Some variants use recycled content or generate fewer emissions. This aligns with growing demand for sustainable products. The versatility of polymer polyol POP makes it a key component in modern mattress production. Its adaptability ensures high-quality results across various foam types. Users benefit from mattresses that combine comfort, support, and durability.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Polymer Polyol Pop 10% 13% 15% 25% 45% for Sponge Foaming Mattress

What is Polymer Polyol Pop used for in sponge foaming mattresses? Polymer Polyol Pop is a key material in making foam for mattresses. It helps create a soft yet supportive structure. The material reacts with other chemicals to form tiny bubbles. This process gives the mattress its cushioning feel. Different percentages change how firm or soft the foam becomes.

Why are there different percentages like 10%, 13%, 15%, 25%, and 45%? The percentage shows how much Polymer Polyol Pop is in the foam mix. Higher percentages make denser, firmer foam. Lower percentages create softer, lighter foam. A 10% mix suits soft mattresses. A 45% mix works for extra-firm support. The choice depends on the comfort level needed.

What benefits does Polymer Polyol Pop offer compared to other materials? It improves foam durability. The foam keeps its shape longer. It resists sagging even after heavy use. The material also helps control costs. It balances quality and price better than many alternatives. Mattresses stay comfortable without breaking down quickly.

Is Polymer Polyol Pop safe for use in mattresses? Yes. It meets safety standards for bedding materials. The foam does not release harmful chemicals. It passes tests for skin contact and air quality. Manufacturers use it widely in products sold globally. Users can trust its safety for daily sleep.

How do I choose the right percentage for my mattress? Think about the firmness you prefer. Soft mattresses often use 10% or 13%. Medium firmness might need 15% or 25%. High-density support requires 45%. Consider who will use the mattress. Heavyweight users may need higher percentages. Lightweight users might prefer lower percentages for softer comfort.

(Polymer Polyol Pop 10% 13% 15% 25% 45% for Sponge Foaming Mattress)