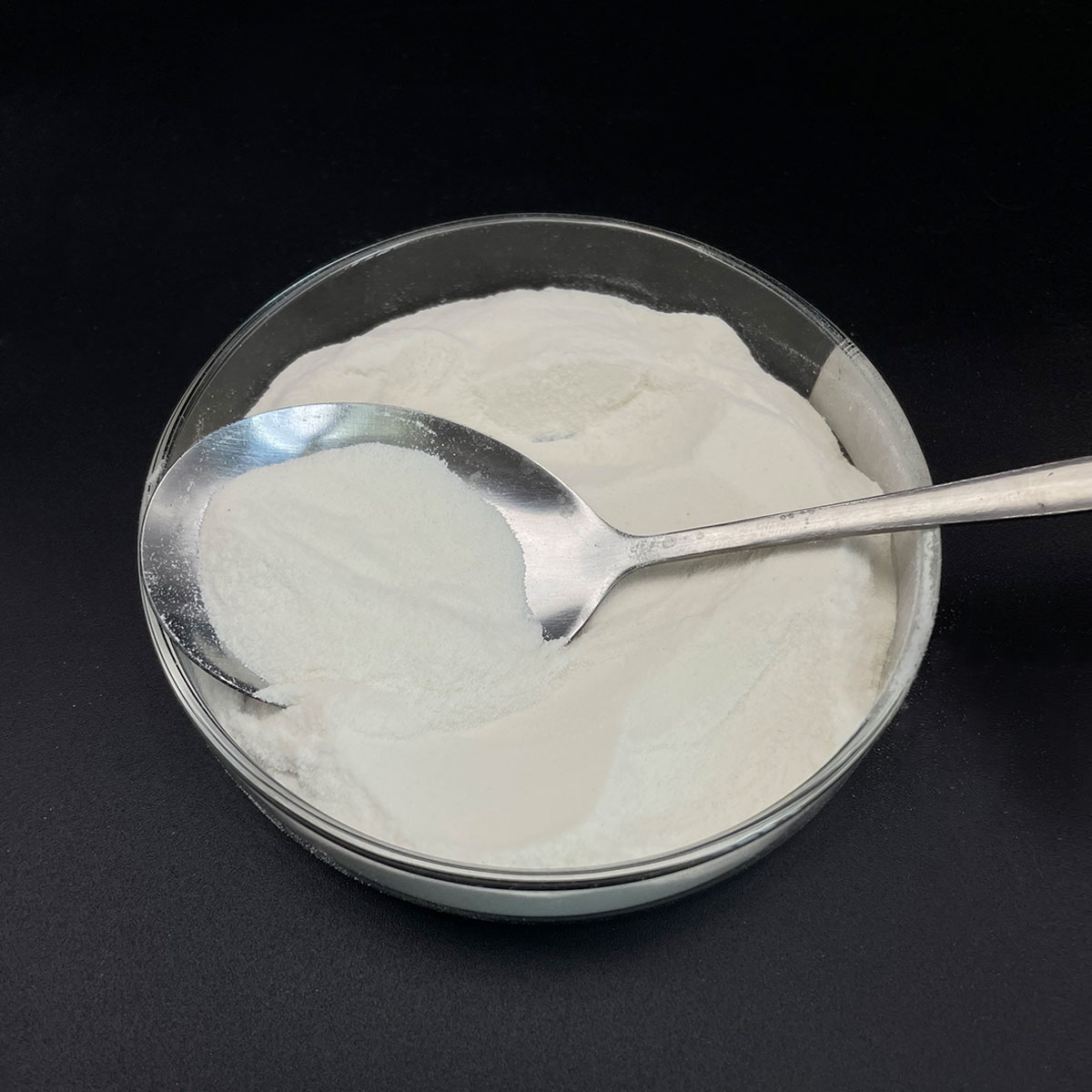

Overview of Polyol/Polymer Polyol /Hot Polyol in Good /Polyol Export

Polymer surfactants, also known as polymeric surfactants or amphiphilic polymers, are high-molecular-weight compounds that combine the properties of traditional low-molecular-weight surfactants with the unique features of polymers. Unlike small molecule surfactants, polymer surfactants offer enhanced stability, improved solubility, and the ability to form more complex structures such as micelles, hydrogels, and vesicles. These macromolecules find applications across a wide range of industries due to their tailored structures and tunable properties, which allow for precise control over interfacial behavior and solution rheology.

Features of Polyol/Polymer Polyol /Hot Polyol in Good /Polyol Export

-

Molecular Weight and Structure: With a much higher molecular weight, polymer surfactants offer enhanced stability in harsh conditions and over prolonged periods compared to small molecule surfactants.

-

Tunability: The structure of polymer surfactants can be precisely engineered to include different functional groups, monomer sequences, and architectures, allowing for specific interactions and properties.

-

Multifunctionality: Apart from surface activity, they can also provide additional functionalities like thickening, rheology modification, and controlled release capabilities.

-

Self-Assembly: Capable of forming sophisticated self-assembled structures like micelles, hydrogels, and vesicles, which can encapsulate or release active ingredients in a controlled manner.

-

Environmental Compatibility: Many polymer surfactants are designed to be biodegradable and less toxic, making them suitable for eco-friendly applications.

-

Temperature and pH Responsiveness: Some polymer surfactants exhibit responsive behavior to changes in temperature or pH, enabling stimuli-responsive systems.

(Polyol/Polymer Polyol /Hot Polyol in Good /Polyol Export)

Specification of Polyol/Polymer Polyol /Hot Polyol in Good /Polyol Export

Polyol, Polymer Polyol, and Hot Polyol are key products used in making polyurethane items. These chemicals work as base elements for foams, finishes, adhesives, and elastomers. The specs for these items guarantee high quality and performance across markets.

Polyol is a polyhydric alcohol containing several hydroxyl groups. It responds with isocyanates to develop polyurethane. Usual kinds consist of polyether polyols and polyester polyols. Polyether polyols use versatility and water resistance. Polyester polyols provide higher mechanical stamina and warmth resistance. Both kinds have varying hydroxyl values and thickness. These worths identify response speed and end product properties.

Polymer Polyol is a changed variation of basic polyol. It consists of dispersed polymer fragments, like styrene-acrylonitrile. This enhances load-bearing capability and foam stability. Polymer Polyol is used in flexible foam production for furniture and automotive seats. Its specifications consist of solid web content percentages and fragment dimension distribution. Higher strong material enhances foam hardness. Fragment size affects foam structure uniformity.

Hot Polyol refers to preheated polyol for processing. Heating decreases thickness, boosting mixing performance with isocyanates. Temperature level ranges in between 40 ° C to 60 ° C. Proper home heating makes sure consistent reaction prices and final product top quality. Warm Polyol needs temperature-controlled storage and dealing with systems.

Trick requirements for these products consist of hydroxyl value, thickness, level of acidity, moisture web content, and pH. Hydroxyl value determines reactivity. Lower hydroxyl values suggest slower responses. Viscosity influences circulation and mixing. Level of acidity and dampness levels influence chemical security. Excess moisture creates foaming issues. pH levels affect service life.

Quality criteria adhere to ISO and ASTM guidelines. Certifications ensure safety and environmental conformity. Product packaging options consist of drums, ISO tanks, and bulk shipments. Drums prevail for little orders. ISO containers suit large-volume transportation. Mass shipments use specialized containers for temperature-sensitive products.

Storage conditions require completely dry, cool environments. Direct exposure to humidity or severe temperature levels weakens high quality. Dealing with involves using nitrogen blankets to prevent oxidation. Routine testing checks for consistency in sets.

Polyol export concentrates on meeting global need for polyurethane applications. Major markets include building and construction, automobile, and furnishings industries. Suppliers focus on reputable logistics and paperwork. Technical support assists customers in selecting the best product qualities. Personalized solutions address details industry needs.

(Polyol/Polymer Polyol /Hot Polyol in Good /Polyol Export)

Applications of Polyol/Polymer Polyol /Hot Polyol in Good /Polyol Export

Polyol works as a key product in making flexible foam items. These foams are used in furniture, cushions, and child seat. The gentleness and longevity of polyol-based foams make them excellent for everyday convenience. Producers likewise make use of polyol to generate adhesives and finishings. These items bond materials firmly and secure surfaces from damages. The adaptability of polyol supports many markets internationally.

Polymer polyol enhances the performance of common polyol. It includes stamina and security to foam frameworks. This makes foam products much better at managing weight without losing form. Automobile parts like seats and dashboards commonly rely on polymer polyol. Industrial tools utilizes it for supporting and insulation. The boosted residential properties help items last longer under hefty usage.

Hot polyol is developed for high-temperature applications. It works well in stiff foams made use of for insulation. Structures and refrigeration systems rely on stiff foam to trap heat or cold. Hot polyol guarantees the foam remains reliable also in extreme problems. This conserves energy and lowers expenses. The construction sector gain from hot polyol in wall surfaces, roofings, and pipelines.

Excellent Polyol Export provides these materials to international markets. The firm focuses on top quality and security. Its items satisfy international criteria for commercial and customer usage. Customers trust fund Excellent Polyol Export for constant efficiency. The company serves industries like automobile, building and construction, and device production.

Polyol, polymer polyol, and warm polyol adjust to various requirements. Flexible foams call for fundamental polyol. Harder applications need polymer polyol. High-heat settings count on warm polyol. Excellent Polyol Export guarantees each kind is readily available for specific needs. The products support efficient manufacturing and reliable output.

Global demand for polyol-based products maintains growing. Suppliers seek materials that stabilize expense and efficiency. Good Polyol Export provides services that align with market patterns. The business’s proficiency assists customers innovate while keeping quality. This drives competition in markets that depend on advanced materials.

Great Polyol Export focuses on sustainability. Manufacturing procedures aim to decrease waste and energy use. Environmentally friendly options are available for eco-conscious buyers. This dedication meets contemporary policies and client assumptions. The focus on sustainability strengthens lasting collaborations.

The duty of polyol in production continues to be critical. Continual improvements in polymer and hot polyol broaden their applications. Excellent Polyol Export stays ahead by upgrading its offerings. Customers get materials that match developing market requirements. This ensures their products remain pertinent in fast-changing markets.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Polyol/Polymer Polyol /Hot Polyol in Good /Polyol Export

What is Polyol? Polyol is a key ingredient in making polyurethane products. It reacts with isocyanates to create materials like foam, coatings, adhesives. Polyols are classified by their base components, such as polyester or polyether. They determine the flexibility, density, durability of the final product. Applications include furniture, insulation, automotive parts. Good Polyol Export supplies high-quality polyols for industrial use.

What is Polymer Polyol? Polymer Polyol is a modified polyol containing polymer particles. These particles improve the load-bearing capacity and stability of polyurethane foams. It is used when products need higher durability, like mattresses or car seats. Good Polyol Export ensures consistent polymer distribution for reliable performance. This type reduces material costs while maintaining quality.

What is Hot Polyol? Hot Polyol refers to polyol processed at elevated temperatures during production. Heating enhances mixing efficiency and reaction speed. It is ideal for manufacturing rigid foams requiring precise temperature control. Good Polyol Export uses advanced heating systems to maintain product integrity. This method saves energy and shortens production cycles.

Why choose Good Polyol Export? Good Polyol Export focuses on strict quality control and customization. Their products meet international standards for purity and performance. They offer technical support to help clients optimize formulations. The company prioritizes timely delivery and competitive pricing. Their polyols suit diverse industries, from construction to textiles.

How to store Polyol safely? Store Polyol in sealed containers away from moisture and direct sunlight. Keep temperatures between 15°C and 30°C to prevent degradation. Avoid contact with water or contaminants to maintain chemical stability. Use appropriate PPE when handling. Good Polyol Export provides detailed storage guidelines to ensure product longevity.

(Polyol/Polymer Polyol /Hot Polyol in Good /Polyol Export)