Overview of Polyurethane Foam Additives Silicone Surfactant

Polymer surfactants, also known as polymeric surfactants or amphiphilic polymers, are high-molecular-weight compounds that combine the properties of traditional low-molecular-weight surfactants with the unique features of polymers. Unlike small molecule surfactants, polymer surfactants offer enhanced stability, improved solubility, and the ability to form more complex structures such as micelles, hydrogels, and vesicles. These macromolecules find applications across a wide range of industries due to their tailored structures and tunable properties, which allow for precise control over interfacial behavior and solution rheology.

Features of Polyurethane Foam Additives Silicone Surfactant

-

Molecular Weight and Structure: With a much higher molecular weight, polymer surfactants offer enhanced stability in harsh conditions and over prolonged periods compared to small molecule surfactants.

-

Tunability: The structure of polymer surfactants can be precisely engineered to include different functional groups, monomer sequences, and architectures, allowing for specific interactions and properties.

-

Multifunctionality: Apart from surface activity, they can also provide additional functionalities like thickening, rheology modification, and controlled release capabilities.

-

Self-Assembly: Capable of forming sophisticated self-assembled structures like micelles, hydrogels, and vesicles, which can encapsulate or release active ingredients in a controlled manner.

-

Environmental Compatibility: Many polymer surfactants are designed to be biodegradable and less toxic, making them suitable for eco-friendly applications.

-

Temperature and pH Responsiveness: Some polymer surfactants exhibit responsive behavior to changes in temperature or pH, enabling stimuli-responsive systems.

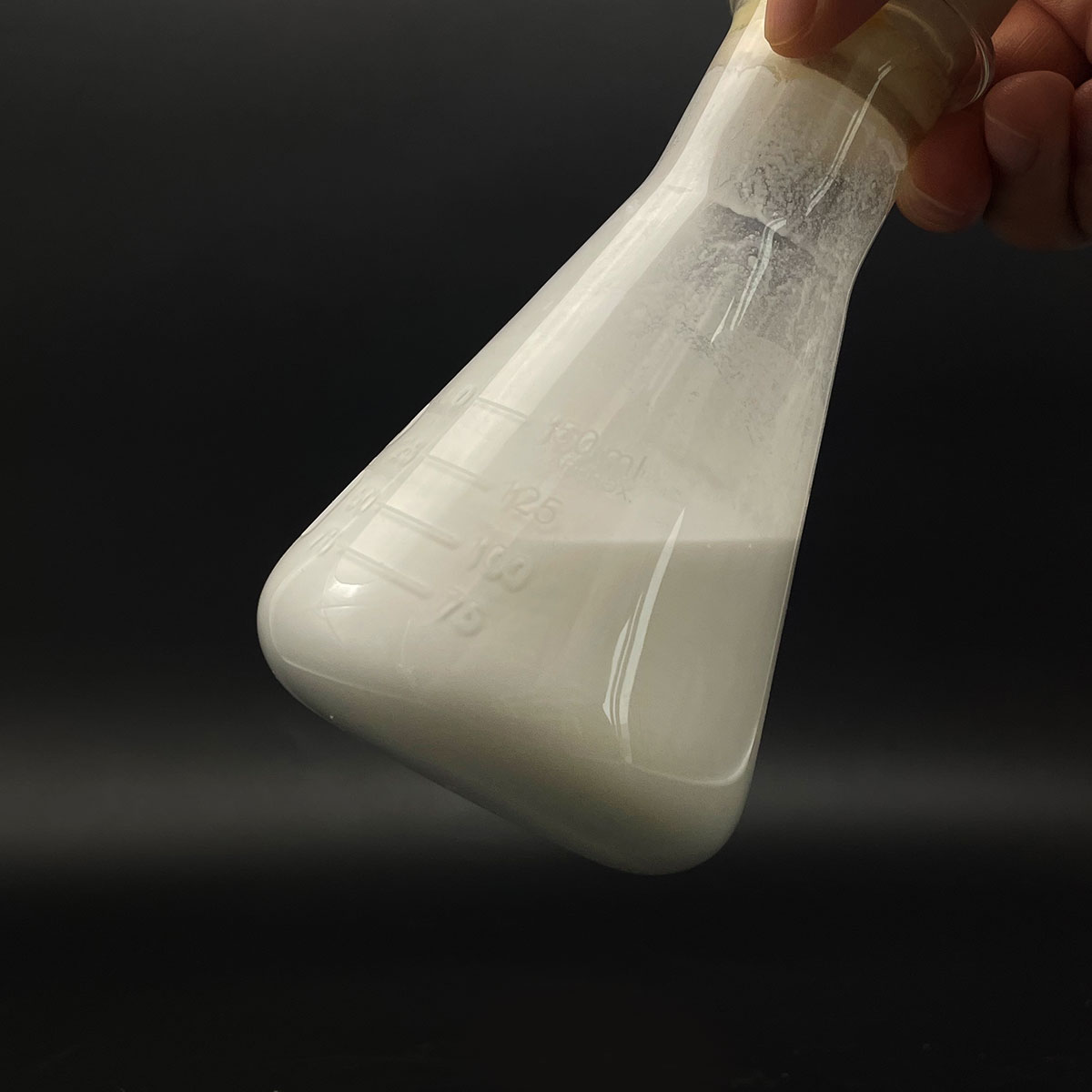

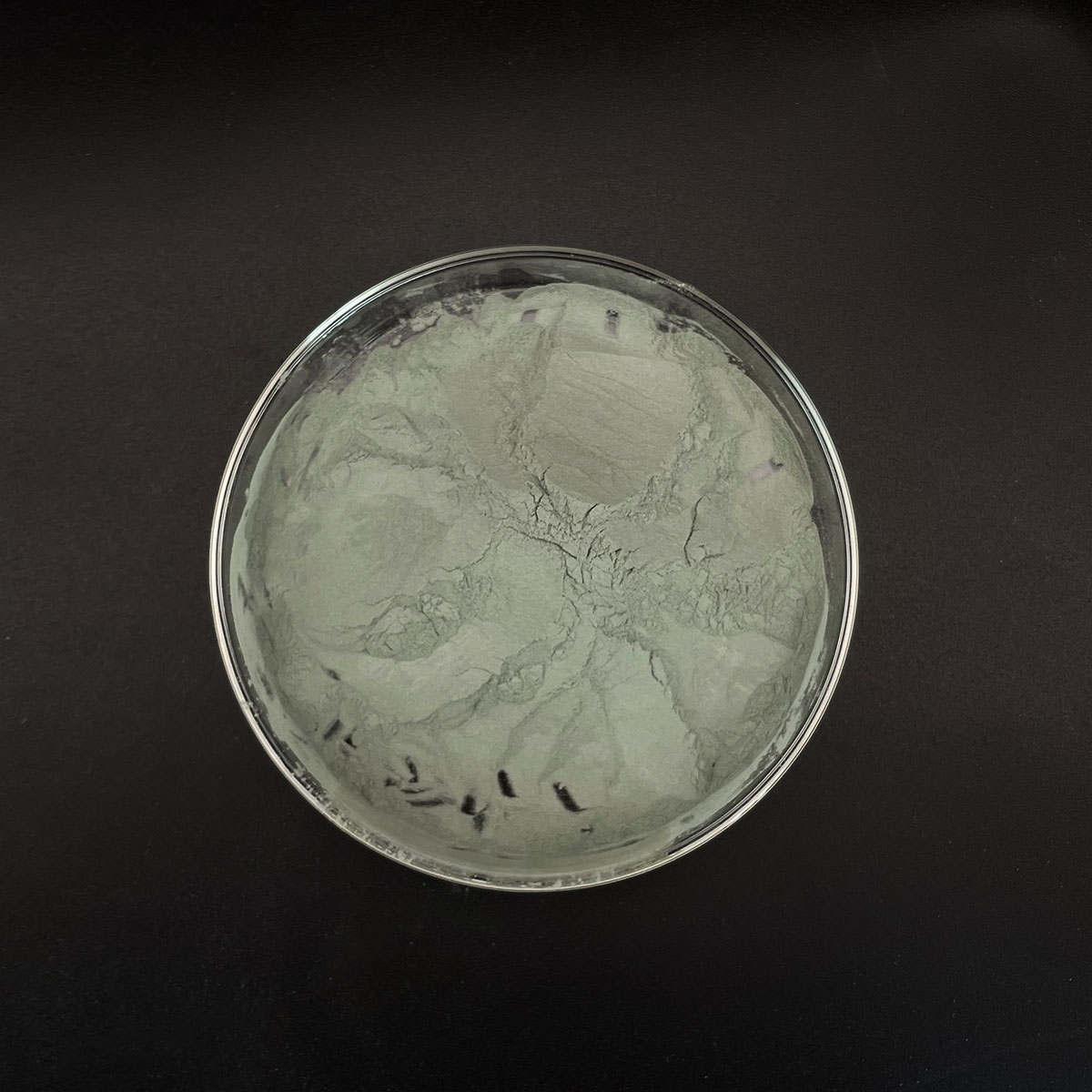

(Polyurethane Foam Additives Silicone Surfactant)

Specification of Polyurethane Foam Additives Silicone Surfactant

Polyurethane foam additives silicone surfactant plays a crucial duty in foam production. It stabilizes foam structure throughout development. This makes certain regular cell size and protects against collapse. The additive adjusts surface stress in the reacting mixture. This equilibrium sustains also bubble circulation. The result is foam with consistent density and smooth structure.

The product works throughout inflexible and versatile foam kinds. It matches applications like insulation panels, mattresses, and vehicle seats. The surfactant improves foam’s thermal security. This aids the material endure high temperatures without breaking down. It also enhances bond in between foam layers. This reinforces end products for long-term usage.

Silicone surfactants can be found in differing viscosities. Options range from reduced to high thickness to match production requirements. The additive withstands dampness and warmth. This extends life span and maintains performance in humid conditions. It mixes easily with polyol blends. Compatibility with other ingredients like stimulants and flame resistants is reputable.

The surfactant lowers problems like spaces or shrinkage. This lessens material waste throughout production. It sustains much faster treating times. Production cycles end up being much more effective. Foam manufacturers accomplish higher output with regular high quality.

Safety and security criteria are fulfilled during handling. The additive has reduced volatility. Harmful fumes during handling are marginal. Appropriate air flow and safety equipment are still encouraged. Storage calls for great, dry problems. Containers needs to stay secured to prevent contamination.

Custom-made solutions are available. Adjustments can optimize foam buildings for particular uses. Technical support helps clients pick the best surfactant grade. Testing makes sure compatibility with existing systems.

This item satisfies market laws for environmental and workplace safety. It consists of no dangerous compounds limited by worldwide requirements. Suppliers reduce risks linked to unpredictable chemicals.

Performance remains secure under diverse processing problems. Temperature variations or mixing speeds have little impact. This dependability fits high-volume commercial settings.

The silicone surfactant adapts to evolving foam modern technologies. It supports advancements in energy-efficient insulation or light-weight automobile materials. Continuous research study refines its applications. Comments from producers guides product improvements.

Dose levels vary based upon foam kind and production goals. Tests determine optimum amounts for cost-effective outcomes. Overuse can influence foam flexibility. Underuse may cause unequal structures. Exact dimension makes certain well balanced outcomes.

The additive integrates smoothly into existing production lines. No major tools upgrades are required. This lowers fostering costs for makers. Training covers secure handling and ideal usage practices.

(Polyurethane Foam Additives Silicone Surfactant)

Applications of Polyurethane Foam Additives Silicone Surfactant

Silicone surfactants play a key function in polyurethane foam manufacturing. These ingredients assist manage foam structure and boost performance. They function by handling air bubbles during blending. This guarantees even cell formation. The outcome is foam with regular thickness and texture.

In flexible foam applications, silicone surfactants support increasing foam. They stop collapse during treating. This is essential for furniture cushions and bed mattress. The foam stays soft yet encouraging. It maintains form in time. Without these ingredients, foam might create unequal surfaces or weak points.

Stiff foam benefits too. Insulation panels and construction products rely on silicone surfactants. The additives develop closed-cell structures. These frameworks catch protecting gases efficiently. Energy efficiency enhances in buildings. The foam additionally ends up being a lot more immune to moisture. This prolongs product life-span in severe atmospheres.

Automotive markets utilize polyurethane foam with silicone surfactants. Car seats and interior parts need durable, lightweight products. The ingredients aid foam comply with molds throughout production. They lower defects in end products. Sound and resonance control boosts. This makes vehicles quieter and more comfy.

Appliances like refrigerators depend on rigid foam insulation. Silicone surfactants make certain correct growth during manufacturing. The foam loads voids totally. Thermal insulation stays reliable. Energy intake decreases. Individuals conserve expenses in time.

Specialty foams make use of these additives for distinct needs. Clinical devices and product packaging products call for exact foam residential or commercial properties. Silicone surfactants change response speeds. They help balance suppleness and elasticity. Customized solutions come to be simpler to achieve.

Ecological aspects issue. Modern silicone surfactants focus on environment-friendly formulas. They minimize volatile natural compounds. Employee security enhances throughout foam processing. End products meet more stringent governing requirements.

Expense performance drives adoption. A percentage of silicone surfactant influences foam top quality significantly. Producers avoid waste from stopped working batches. Production rates raise. Constant output maintains clients satisfied.

Compatibility with various other ingredients is crucial. Silicone surfactants mix well with drivers and flame retardants. Formulations stay stable. Efficiency remains foreseeable across different manufacturing problems.

Research study remains to increase applications. New silicone surfactant variations deal with arising industry demands. They adjust to advanced production methods. Polyurethane foam stays relevant in advancing markets.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Polyurethane Foam Additives Silicone Surfactant

Polyurethane foam additives silicone surfactants help control foam formation and structure. They improve foam quality and performance. Here are five common questions about these products.

What is a silicone surfactant in polyurethane foam additives? A silicone surfactant is a chemical additive. It stabilizes gas bubbles during foam production. It ensures uniform cell structure. It prevents foam collapse or uneven texture.

How does a silicone surfactant work? It reduces surface tension in the liquid foam mixture. This allows gas bubbles to form evenly. It balances bubble growth and stabilization. The result is consistent foam density and cell size.

What benefits do silicone surfactants provide? They enhance foam stability during production. They improve insulation properties in final products. They reduce defects like voids or shrinkage. They adapt to different foam types, including flexible or rigid applications.

Are there different silicone surfactants for different foams? Yes. Formulas vary based on foam requirements. Flexible foam surfactants prioritize elasticity. Rigid foam surfactants focus on structural strength. Specialty foams use tailored blends for unique needs.

How do I choose the right silicone surfactant? Match the surfactant to your foam type and process. Consider reaction speed, equipment, and end-use demands. Test small batches first. Consult technical data sheets for compatibility guidance.

(Polyurethane Foam Additives Silicone Surfactant)