Overview of Powder Chloroacetic Acid Falke Monochloroacetic Acid for CMC

Amphoteric surfactants are a unique class of surface-active agents that possess both cationic and anionic properties, depending on the pH of the system they are in. They contain both a positively charged group (like a quaternary ammonium salt) and a negatively charged group (such as a carboxylate or sulfonate), which can ionize depending on the surrounding conditions. This dual nature grants them exceptional versatility, making them effective in a wide range of pH environments and compatible with other surfactant types. They are known for their mildness and excellent dermatological compatibility, rendering them particularly suitable for personal care applications.

Features of Powder Chloroacetic Acid Falke Monochloroacetic Acid for CMC

-

pH Responsiveness: Their charge varies with pH, becoming cationic in acidic conditions and anionic in alkaline, with a zwitterionic (neutral) state at the isoelectric point.

-

Mildness: Known for being gentle on skin and eyes, making them ideal for sensitive applications like baby care and personal hygiene products.

-

Foaming Properties: Can generate rich, stable foam even in hard water conditions, enhancing their use in cleaning products.

-

Emulsification: Efficient emulsifiers capable of forming both oil-in-water (O/W) and water-in-oil (W/O) emulsions, depending on the formulation and pH.

-

Compatibility: Because they have both anionic and cationic properties, they are compatible with other types of surfactants and can work synergistically to enhance cleaning effects.

-

Biodegradability: Many amphoteric surfactants are readily biodegradable, contributing to their environmentally friendly profile.

(Powder Chloroacetic Acid Falke Monochloroacetic Acid for CMC)

Specification of Powder Chloroacetic Acid Falke Monochloroacetic Acid for CMC

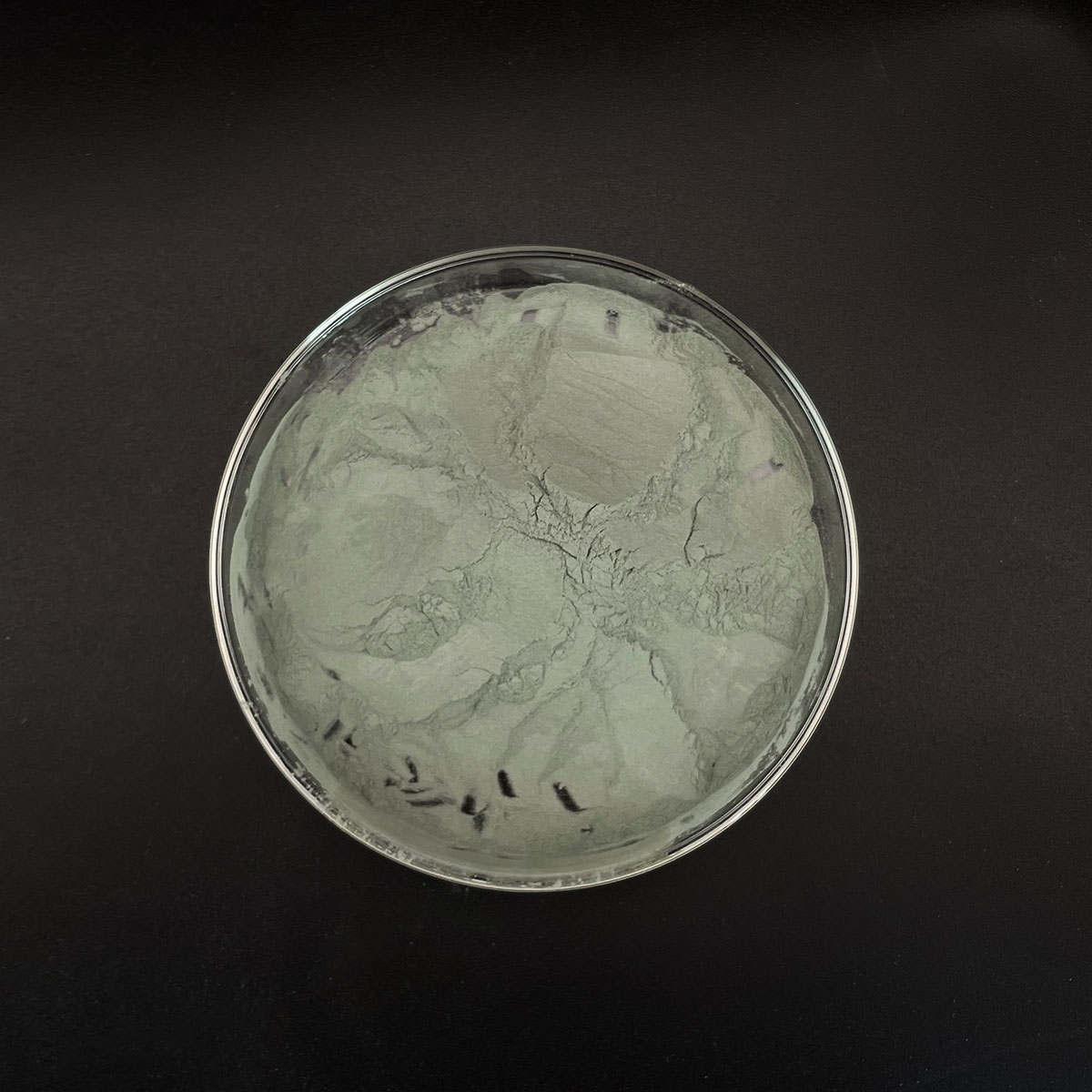

Powder Chloroacetic Acid Falke Monochloroacetic Acid is a high-quality chemical item developed for usage in carboxymethyl cellulose (CMC) production. This product satisfies stringent sector requirements. It makes certain reputable performance in commercial applications. The material looks like a white crystalline powder. It has a solid acidic smell. The item is extremely soluble in water. It dissolves easily in ethanol. The purity degree is a minimum of 99%. Wetness web content is regulated below 0.5%. This prevents clumping during storage. The item is packaged in long lasting, moisture-resistant containers. Each container holds 25 kilos. The product packaging product is high-density polyethylene (HDPE). This ensures security throughout transport.

The chemical formula is C2H3ClO2. The molecular weight is 94.49 g/mol. The melting point varies in between 63 ° C and 65 ° C. The boiling point is about 189 ° C. The item is hygroscopic. Correct storage conditions are crucial. Store in a trendy, dry location. Avoid direct sunshine. Stay clear of contact with incompatible materials. These consist of strong oxidizers, bases, and metals. Direct exposure to moisture need to be minimized.

Safety safety measures are essential when handling this item. Put on safety handwear covers. Usage safety and security goggles. Guarantee ample ventilation. Stay clear of inhaling dust or vapors. In instance of skin contact, laundry promptly with water. Look for medical interest if irritation continues. The product is corrosive. Take care of with like avoid accidents.

In CMC production, this chloroacetic acid functions as a vital reagent. It promotes the carboxymethylation procedure. This modifies cellulose to boost water solubility. The outcome is a secure, high-performance CMC product. Applications cover food, pharmaceuticals, and commercial sectors. The acid’s pureness makes sure consistent reaction efficiency. This reduces waste in production.

Quality control examinations are carried out at every phase. These consist of pH checks, dampness analysis, and purity verification. Certificates of evaluation (CoA) are given with each batch. This ensures compliance with client requirements. The item is made under stringent high quality monitoring systems. International criteria like ISO 9001 are complied with.

Technical assistance is available for clients. Advice on storage, dealing with, and application optimization is offered. Personalized packaging choices can be organized. Mass orders are suited for large-scale procedures. The product is delivered around the world. Shipment timelines depend on area.

This chloroacetic acid is a preferred selection for CMC producers. Its regular quality supports reliable, scalable manufacturing procedures. Individuals benefit from minimized downtime. Item efficiency straightens with sector demands.

(Powder Chloroacetic Acid Falke Monochloroacetic Acid for CMC)

Applications of Powder Chloroacetic Acid Falke Monochloroacetic Acid for CMC

Powder Chloroacetic Acid, especially Falke Monochloroacetic Acid, plays a critical role in creating carboxymethyl cellulose (CMC). CMC is a functional additive utilized throughout sectors. Its capacity to thicken, maintain, and retain moisture makes it important. Falke’s high-purity Monochloroacetic Acid ensures effective CMC synthesis.

In food manufacturing, CMC improves structure and shelf life. It avoids ice crystal development in desserts. It stabilizes dressings and sauces. Falke’s acid makes it possible for constant CMC high quality, satisfying food security standards.

Drugs rely on CMC for medication formulas. It binds tablets, controls launch prices, and enhances solubility. Falke’s item ensures pureness, critical for medical-grade CMC. This minimizes contamination dangers in sensitive applications.

Cosmetics make use of CMC to adjust viscosity. Lotions, creams, and hair shampoos gain smooth structures. Falke’s acid sustains consistent responses throughout CMC manufacturing. This causes reliable efficiency in personal care products.

Industrial applications include adhesives, fabrics, and paper. CMC acts as a binder in adhesives. It improves color absorption in materials. It enhances paper items. Falke’s Monochloroacetic Acid provides the reactivity needed for these processes.

The chemical’s great powder kind enables simple handling. It liquifies swiftly in responses. This quickens CMC manufacturing. Manufacturers gain from reduced processing time and prices.

Falke’s production approaches prioritize safety. Rigorous quality control decreases impurities. This makes certain stable CMC result. Customers avoid incongruities in their end products.

Environmental considerations matter. Falke optimizes synthesis effectiveness. This reduces waste generation. Business meet sustainability objectives without giving up performance.

Research study continues to broaden CMC makes use of. Falke’s Monochloroacetic Acid adjusts to brand-new formulas. Its convenience sustains advancement in biodegradable products and advanced coverings.

The acid’s role in CMC emphasizes its commercial value. Falke’s commitment to quality and dependability makes it a recommended choice. Customers trust its consistency throughout diverse applications.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Powder Chloroacetic Acid Falke Monochloroacetic Acid for CMC

What is Powder Chloroacetic Acid used for in CMC production? Powder Chloroacetic Acid is a main ingredient for making carboxymethyl cellulose (CMC). It bonds with cellulose to create water-soluble CMC. This allows CMC to thicken, stabilize, or hold moisture in items like food, paper, textiles, or detergents. The acid’s reactivity makes it vital for modifying cellulose structure.

How should Falke Monochloroacetic Acid be stored safely? Keep the powder in a cool, dry area with no direct sunlight. Avoid places with high humidity or temperature changes. Use sealed, non-reactive containers to prevent moisture absorption. Keep away from open flames or sparks. Check containers regularly for damage or leaks.

What safety precautions are needed when handling this chemical? Always wear protective gloves, goggles, and lab coats. Use a respirator if dust is present. Work in areas with good airflow or exhaust systems. Do not eat, drink, or touch your face during handling. Rinse skin or eyes with water immediately if exposed. Store separately from alkalis or oxidizers.

What are the technical specifications of this product? The powder is typically 98-99% pure. Particle size is fine, around 50-200 microns. It dissolves fully in water and ethanol. Melting point is roughly 63°C. Moisture content stays below 0.5% to ensure stability. Exact grades vary by manufacturer.

How does this acid affect the quality of CMC? Pure chloroacetic acid produces CMC with uniform substitution levels. This improves viscosity and solubility in final products. Lower purity creates uneven reactions, reducing performance. Proper dosing ensures CMC meets requirements for pharmaceuticals, adhesives, or food additives.

(Powder Chloroacetic Acid Falke Monochloroacetic Acid for CMC)