Overview of Pre-Dispersed Pigment for Film Pressure on EVA, PE, TPU and PVC

Specialty surfactants are a diverse class of surface-active agents designed for specific, high-performance applications where standard surfactants may not meet the required performance criteria. These surfactants are often tailor-made to exhibit unique properties, such as extreme temperature stability, low foam formation, high solubility in specific solvents, or compatibility with particular chemical systems. They are crucial components in formulations demanding precision, enhanced functionality, or strict regulatory compliance, found across industries from pharmaceuticals to advanced materials manufacturing.

Features of Pre-Dispersed Pigment for Film Pressure on EVA, PE, TPU and PVC

-

Customized Performance: Developed to meet exacting specifications, offering tailored functionalities beyond generic surfactants.

-

High Efficiency: Designed to work at lower concentrations or under challenging conditions, increasing performance per unit mass.

-

Unique Properties: May exhibit special traits such as non-flammability, low toxicity, high thermal stability, or specific solubility profiles.

-

Regulatory Compliance: Often formulated to meet stringent industry-specific regulations, such as food-grade, medical, or eco-friendly standards.

-

Innovative Chemistry: Incorporate novel chemistries, such as fluorinated, silicone-based, or bio-based structures, to achieve specialized performance.

-

Synergistic Effects: Frequently used in combination with other surfactants to enhance or augment performance in complex formulations.

(Pre-Dispersed Pigment for Film Pressure on EVA, PE, TPU and PVC)

Specification of Pre-Dispersed Pigment for Film Pressure on EVA, PE, TPU and PVC

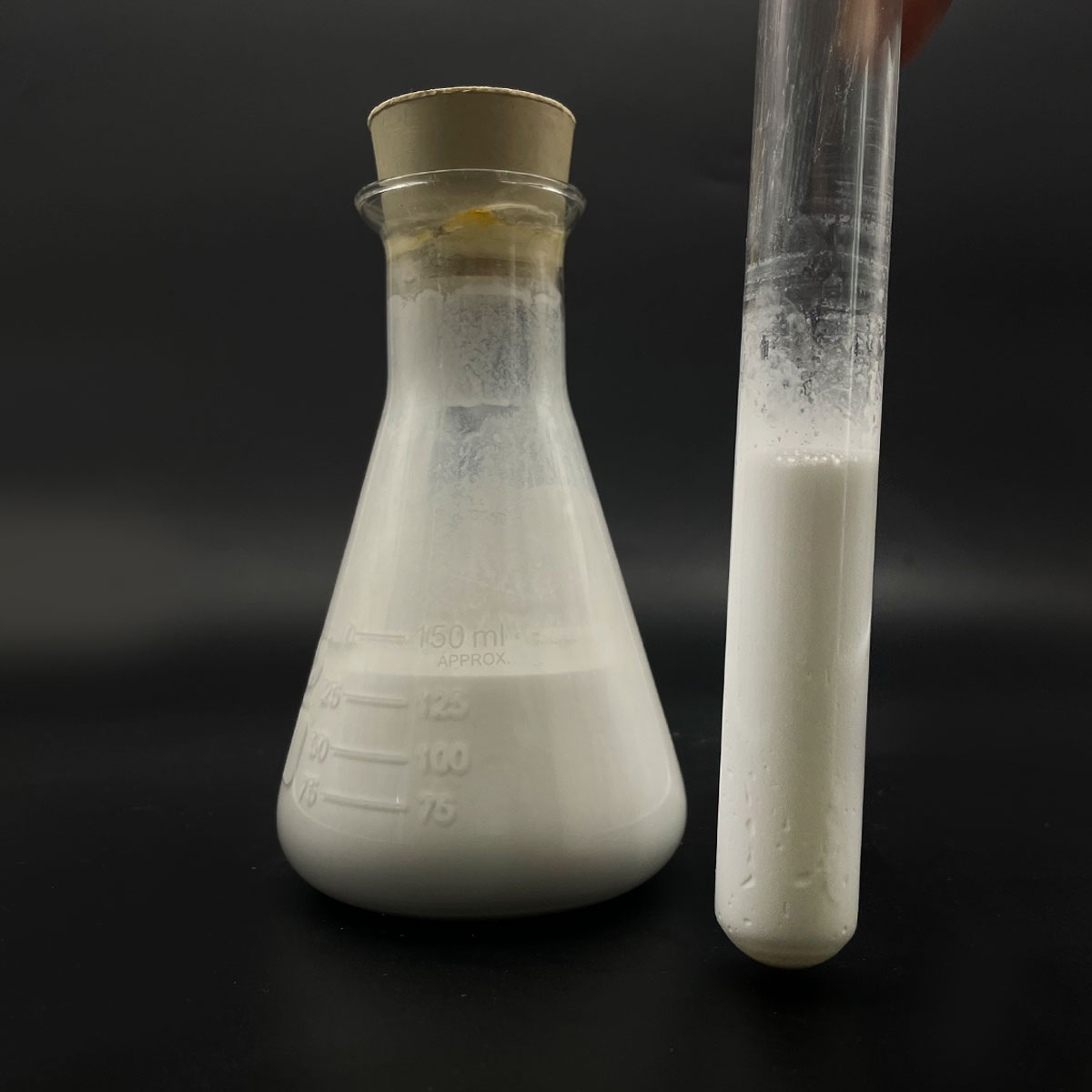

Pre-Dispersed Pigment for Movie Stress on EVA, PE, TPU, and PVC supplies high-performance shade options for pressure-sensitive film applications. This product is made to incorporate efficiently with ethylene-vinyl acetate (EVA), polyethylene (PE), polycarbonate polyurethane (TPU), and polyvinyl chloride (PVC) bases. It guarantees regular shade dispersion, minimizing processing time and enhancing production efficiency.

The pigment comes in great bit type, with a typical dimension under 5 microns. This permits also circulation within polymer matrices, avoiding streaks or uneven shading. It collaborates with both solvent-based and water-based film pressure systems. The formula consists of stabilizers to withstand heat deterioration throughout high-temperature processing, maintaining vibrancy approximately 220 ° C.

Concentration levels are maximized for simple mixing. Customers attain full-color stamina with marginal additive quantities, decreasing product waste. Compatibility with usual plasticizers and adhesives makes certain no interference with movie adaptability or bond residential properties. The pigment is non-reactive, making it safe for use in movies needing call with skin or food.

Processing advantages include lowered blending time. The pre-dispersed style removes clumping, so no additional grinding or milling is required. This accelerate manufacturing cycles. Color consistency stays steady across sets, vital for massive manufacturing.

Applications cover adhesive movies, industrial labels, decorative sheets, and protective coverings. It carries out well in automobile indoor films, packaging laminates, and textile finishes. The pigment withstands fading from UV direct exposure and chemicals, perfect for outdoor or harsh-environment use.

Custom color matching is offered. Adjustments can be created specific opacity degrees or coating preferences (matte, shiny). The item meets worldwide safety and security standards, consisting of REACH and RoHS, making certain no hazardous substances are present.

Packaging choices consist of 25kg bags or 1-ton mass containers. Storage suggestions highlight maintaining the item in an awesome, completely dry location to prevent wetness absorption. Shelf life is 18 months from production day when saved correctly.

This pigment streamlines movie production while preserving high shade top quality. It supports diverse industrial demands, supplying reliability for suppliers focused on efficiency and efficiency.

(Pre-Dispersed Pigment for Film Pressure on EVA, PE, TPU and PVC)

Applications of Pre-Dispersed Pigment for Film Pressure on EVA, PE, TPU and PVC

Pre-dispersed pigments for movie stress on EVA, PE, TPU, and PVC offer efficient color solutions for commercial applications. These pigments come ready to mix, saving effort and time in manufacturing. They blend smoothly with polymer bases, guaranteeing even color distribution without globs or streaks. This makes them excellent for high-quality films utilized in product packaging, auto insides, sporting activities equipment, and building materials.

EVA films gain from pre-dispersed pigments because of their versatility and longevity. The pigments bond well with EVA’s structure, maintaining shade security under UV direct exposure and mechanical stress. This is important for products like footwear soles or athletic tools, where fading or splitting is unacceptable. The pigments also stand up to movement, protecting against color transfer during processing or usage.

PE movies rely on consistent shade for customer packaging and agricultural covers. Pre-dispersed pigments work with PE’s low surface energy, making certain dynamic shades stay undamaged throughout extrusion or lamination. They take care of high-speed assembly line without clogging devices, decreasing downtime. Their thermal security protects against staining also when subjected to warm during movie forming.

TPU films demand pigments that adjust to elastic residential properties. Pre-dispersed alternatives stretch with TPU without damaging, making them ideal for clinical devices or waterproof clothing. The pigments retain illumination after duplicated flexing or washing. They also satisfy safety and security standards for skin call, vital in health care or wearable technology applications.

PVC films use these pigments for inflexible or versatile layouts, like signage or artificial natural leather. The pigments withstand the acidic atmosphere of PVC handling, avoiding reactions that modify shade. They give opacity for concealing substrates or creating bold visuals in advertising materials. Warm resistance guarantees shades remain real during molding or welding actions.

Compatibility with several polymers streamlines stock administration for makers. Customers avoid separate pigment systems for different products, reducing prices and mistakes. The great fragment dimension of pre-dispersed pigments enhances gloss and appear finish, boosting item charm. Changing pigment concentration permits precise control over openness or coverage, conference diverse consumer demands.

Ecological factors issue. These pigments minimize waste by eliminating diffusion steps, reducing power usage. They abide by guidelines on heavy steels and unpredictable organic substances, sustaining eco-friendly manufacturing.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Pre-Dispersed Pigment for Film Pressure on EVA, PE, TPU and PVC

Pre-dispersed pigments for film pressure on EVA, PE, TPU, and PVC are ready-to-use colorants. These pigments mix evenly into polymer bases. They ensure consistent color without clumping. They work for films needing high-pressure applications. Their design suits materials like ethylene-vinyl acetate (EVA), polyethylene (PE), thermoplastic polyurethane (TPU), and polyvinyl chloride (PVC).

Are pre-dispersed pigments compatible with EVA, PE, TPU, and PVC? Yes. These pigments are formulated specifically for these polymers. They bond well during processing. They avoid issues like color fading or uneven distribution. Each material type has a tailored pigment blend. This ensures performance matches the base polymer’s requirements.

How do pre-dispersed pigments improve film pressure resistance? The pigments distribute evenly in the polymer matrix. This reduces weak spots caused by uneven coloring. Uniform dispersion strengthens the film’s structure. It handles pressure better during manufacturing or end use. The pigments also resist heat and shear stress during processing.

What processing benefits do pre-dispersed pigments offer? They eliminate steps like grinding or mixing raw pigments. This saves time and reduces errors. They integrate directly into the polymer melt. This cuts production costs and energy use. They work with common methods like extrusion or calendering.

How should pre-dispersed pigments be stored and handled? Store them in sealed containers away from moisture. Keep them in cool, dry areas below 30°C. Avoid direct sunlight. Follow the supplier’s shelf-life guidelines. Wear gloves and masks when handling to prevent contamination. Clean equipment after use to avoid cross-mixing.

(Pre-Dispersed Pigment for Film Pressure on EVA, PE, TPU and PVC)