Overview of PU Additives Silicone Surfactant for Flexible/Rigid Foam Production

Polymer surfactants, also known as polymeric surfactants or amphiphilic polymers, are high-molecular-weight compounds that combine the properties of traditional low-molecular-weight surfactants with the unique features of polymers. Unlike small molecule surfactants, polymer surfactants offer enhanced stability, improved solubility, and the ability to form more complex structures such as micelles, hydrogels, and vesicles. These macromolecules find applications across a wide range of industries due to their tailored structures and tunable properties, which allow for precise control over interfacial behavior and solution rheology.

Features of PU Additives Silicone Surfactant for Flexible/Rigid Foam Production

-

Molecular Weight and Structure: With a much higher molecular weight, polymer surfactants offer enhanced stability in harsh conditions and over prolonged periods compared to small molecule surfactants.

-

Tunability: The structure of polymer surfactants can be precisely engineered to include different functional groups, monomer sequences, and architectures, allowing for specific interactions and properties.

-

Multifunctionality: Apart from surface activity, they can also provide additional functionalities like thickening, rheology modification, and controlled release capabilities.

-

Self-Assembly: Capable of forming sophisticated self-assembled structures like micelles, hydrogels, and vesicles, which can encapsulate or release active ingredients in a controlled manner.

-

Environmental Compatibility: Many polymer surfactants are designed to be biodegradable and less toxic, making them suitable for eco-friendly applications.

-

Temperature and pH Responsiveness: Some polymer surfactants exhibit responsive behavior to changes in temperature or pH, enabling stimuli-responsive systems.

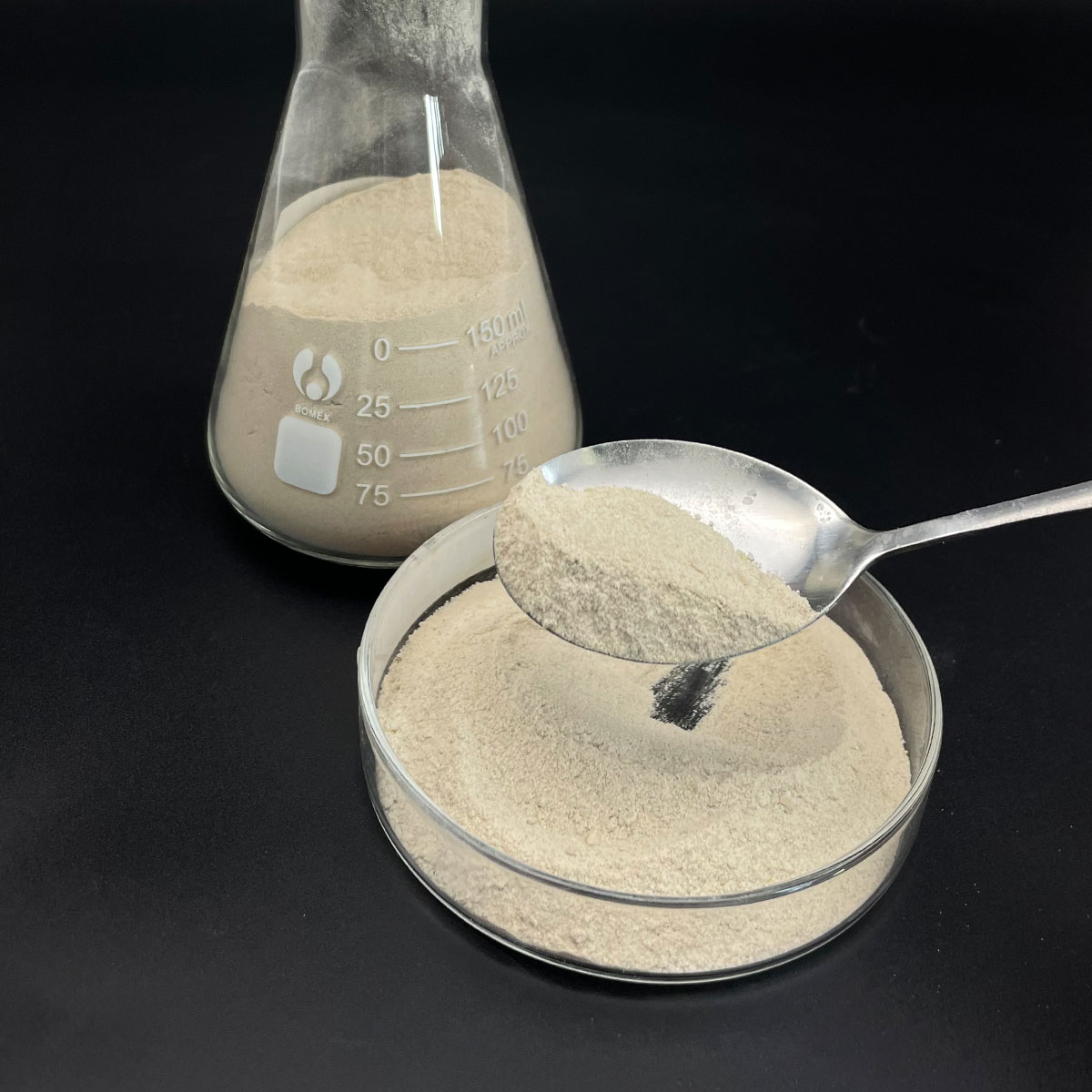

(PU Additives Silicone Surfactant for Flexible/Rigid Foam Production)

Specification of PU Additives Silicone Surfactant for Flexible/Rigid Foam Production

This silicone surfactant is for flexible and rigid polyurethane foam manufacturing. It makes the foam better. The surfactant assists manage the bubbles developing in the fluid foam mix. This control is vital for obtaining a good foam framework.

It makes the foam cells consistent and stable. Steady cells stop the foam from falling down while it climbs and sets. You get foam with regular thickness and really feel. The surfactant likewise helps the liquid components mix effectively. Great blending means the foam cures properly.

In flexible foams, like furniture padding, this surfactant offers a soft, open cell framework. Open cells allow air circulation easily with the foam. This makes the foam comfy and springy. It recuperates well after you sit on it.

For rigid foams, like insulation panels, the surfactant creates really fine, closed cells. Closed cells trap gas efficiently. This gives stiff foam its outstanding thermal insulation power. The foam stays strong and dimensionally stable.

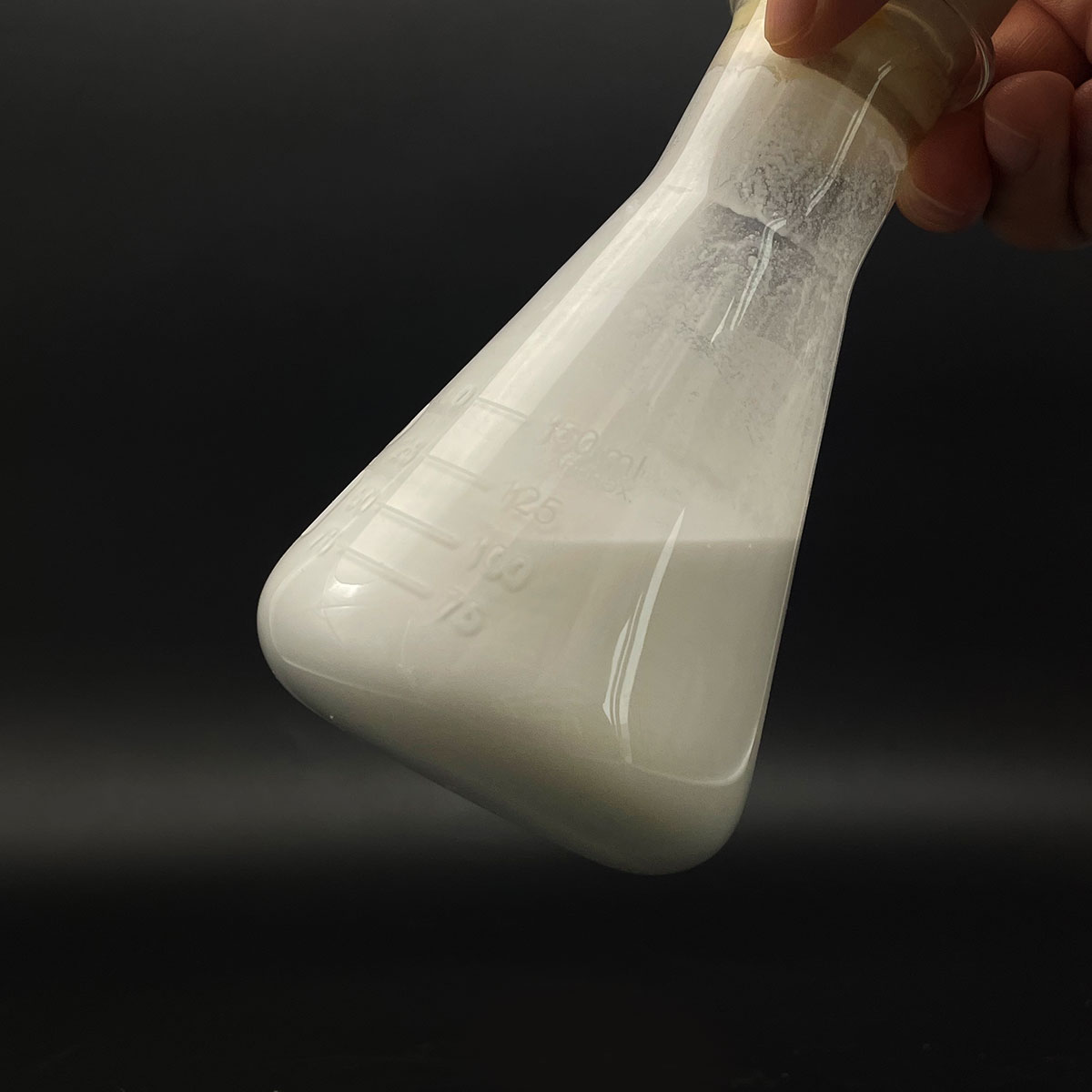

The product works with various polyol systems. It deals with common polyether polyols and polymer polyols. Compatibility is good. The surfactant is a clear liquid. Its viscosity is medium. You handle it easily in production. The typical usage degree is in between 1.0 and 2.5 parts per hundred components of polyol. Specific dosage relies on your specific foam dish and machine settings. Storage is straightforward. Keep it secured in a trendy, dry place away from straight sun. The life span is long when kept right.

(PU Additives Silicone Surfactant for Flexible/Rigid Foam Production)

Applications of PU Additives Silicone Surfactant for Flexible/Rigid Foam Production

Silicone surfactants are crucial ingredients for making polyurethane foam. They aid manage exactly how the foam types. These ingredients work throughout the chemical reaction. They stabilize the foam as it broadens. This avoids collapse or unequal bubbles. Great foam framework relies on them.

Versatile foam needs silicone surfactants. This foam is soft and made use of in furnishings or cushions. The surfactant makes tiny air pockets uniform. It makes sure the foam rises evenly. After that the foam remains adaptable however encouraging. Without it, furnishings pillows might feel lumpy or wear out quickly. Car seats and bed linens rely on this smooth appearance.

Stiff foam additionally uses silicone surfactants. This foam is tough and found in insulation panels or refrigerators. Right here surfactants produce shut tiny cells. These cells catch heat-blocking gases inside. The foam ends up being a solid insulator. Structures and home appliances use this for energy financial savings. Appropriate cell structure quits warmth loss successfully.

These surfactants solve common foam problems. They lower surface area tension in the mix. Bubbles merge less so cells remain separate. Foam density stays constant throughout. Processing becomes less complicated for suppliers. Less material waste happens. Final products meet top quality targets regularly.

Choosing the ideal silicone surfactant matters. Flexible foam needs one type for stretchiness. Stiff foam needs another for limited cells. Suppliers examine various alternatives. They pick what suits their foam recipe best. Correct use enhances foam performance every time.

Silicone surfactants deal with challenging manufacturing problems. They work with various chemicals and temperature levels. Trustworthy results originate from their use. Foam manufacturers trust them daily.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of PU Additives Silicone Surfactant for Flexible/Rigid Foam Production

PU Additives Silicone Surfactant FAQs – Flexible & Rigid Foam

What does a silicone surfactant do in foam?

It controls bubble formation. The surfactant helps mix liquids well. It stabilizes bubbles as foam rises. This prevents bubbles collapsing too soon. It helps create uniform cell structure. Good foam needs this.

Why silicone specifically?

Silicone molecules work best here. They lower surface tension effectively. Other types don’t work as well. Silicone gives the right balance. It makes foam stable and open-celled. Foam quality depends on this.

How much surfactant do we add?

The amount varies. It depends on the foam type. It depends on the specific formula. Flexible foam often uses less. Rigid foam might need more. Always follow supplier guidelines. Start with their recommended dosage. Test small batches first. Adjust if needed.

How should we store this surfactant?

Store it properly. Keep containers sealed tight. Keep it in a cool, dry place. Avoid extreme temperatures. Avoid moisture getting in. Don’t let it freeze. Shelf life is usually long. Check the product label. Use oldest stock first.

What if our foam has problems like splits or shrinkage?

Surfactant issues could be the cause. Wrong surfactant type might be used. The dosage might be incorrect. Mixing might be poor. Check your surfactant choice first. Verify the amount added. Ensure good mixing. Consult your supplier. They can help diagnose it.

(PU Additives Silicone Surfactant for Flexible/Rigid Foam Production)