Overview of Redispersible Polymer Powder Chemical Rdp for Mortar Adhesives Concrete Admixture

Polymer surfactants, also known as polymeric surfactants or amphiphilic polymers, are high-molecular-weight compounds that combine the properties of traditional low-molecular-weight surfactants with the unique features of polymers. Unlike small molecule surfactants, polymer surfactants offer enhanced stability, improved solubility, and the ability to form more complex structures such as micelles, hydrogels, and vesicles. These macromolecules find applications across a wide range of industries due to their tailored structures and tunable properties, which allow for precise control over interfacial behavior and solution rheology.

Features of Redispersible Polymer Powder Chemical Rdp for Mortar Adhesives Concrete Admixture

-

Molecular Weight and Structure: With a much higher molecular weight, polymer surfactants offer enhanced stability in harsh conditions and over prolonged periods compared to small molecule surfactants.

-

Tunability: The structure of polymer surfactants can be precisely engineered to include different functional groups, monomer sequences, and architectures, allowing for specific interactions and properties.

-

Multifunctionality: Apart from surface activity, they can also provide additional functionalities like thickening, rheology modification, and controlled release capabilities.

-

Self-Assembly: Capable of forming sophisticated self-assembled structures like micelles, hydrogels, and vesicles, which can encapsulate or release active ingredients in a controlled manner.

-

Environmental Compatibility: Many polymer surfactants are designed to be biodegradable and less toxic, making them suitable for eco-friendly applications.

-

Temperature and pH Responsiveness: Some polymer surfactants exhibit responsive behavior to changes in temperature or pH, enabling stimuli-responsive systems.

(Redispersible Polymer Powder Chemical Rdp for Mortar Adhesives Concrete Admixture)

Specification of Redispersible Polymer Powder Chemical Rdp for Mortar Adhesives Concrete Admixture

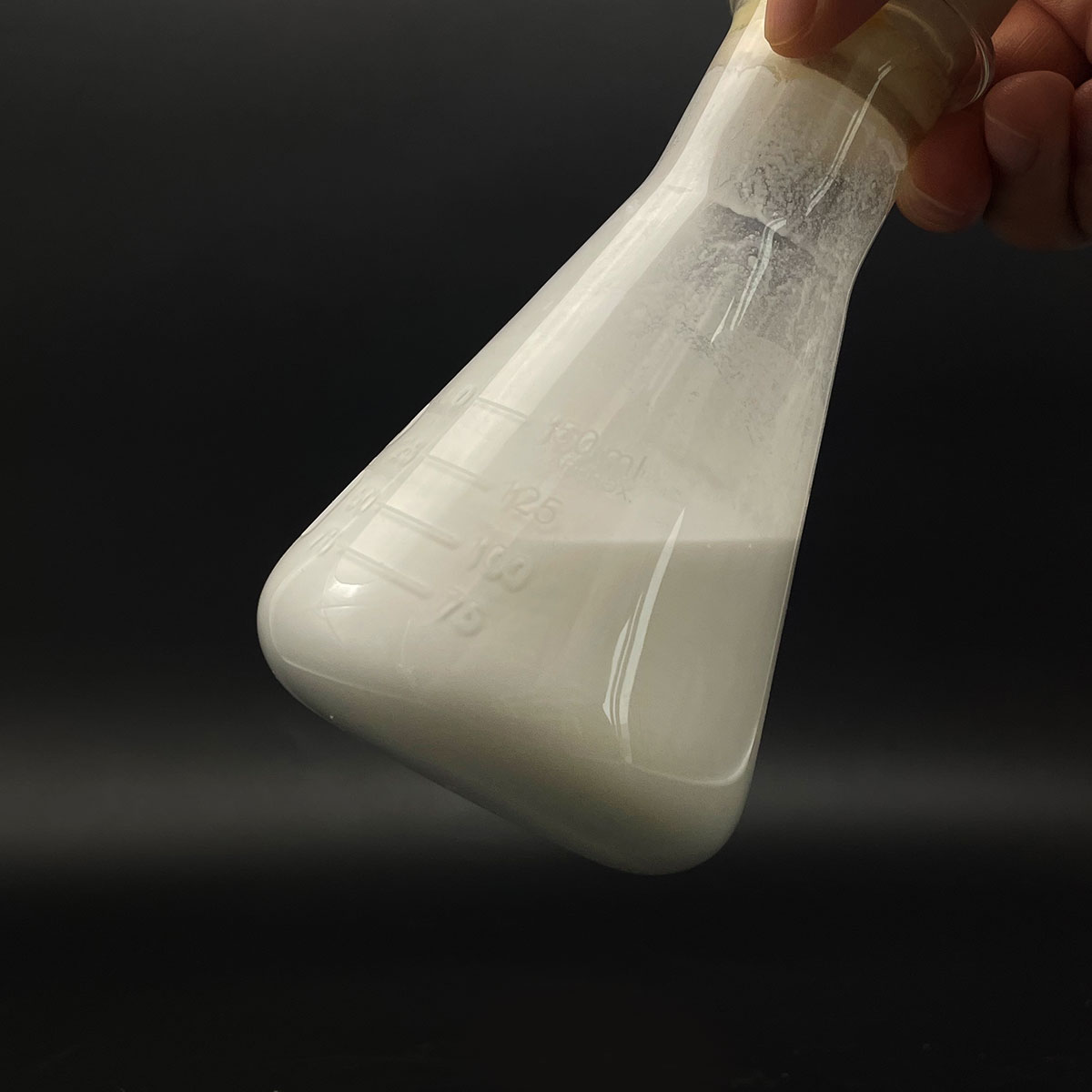

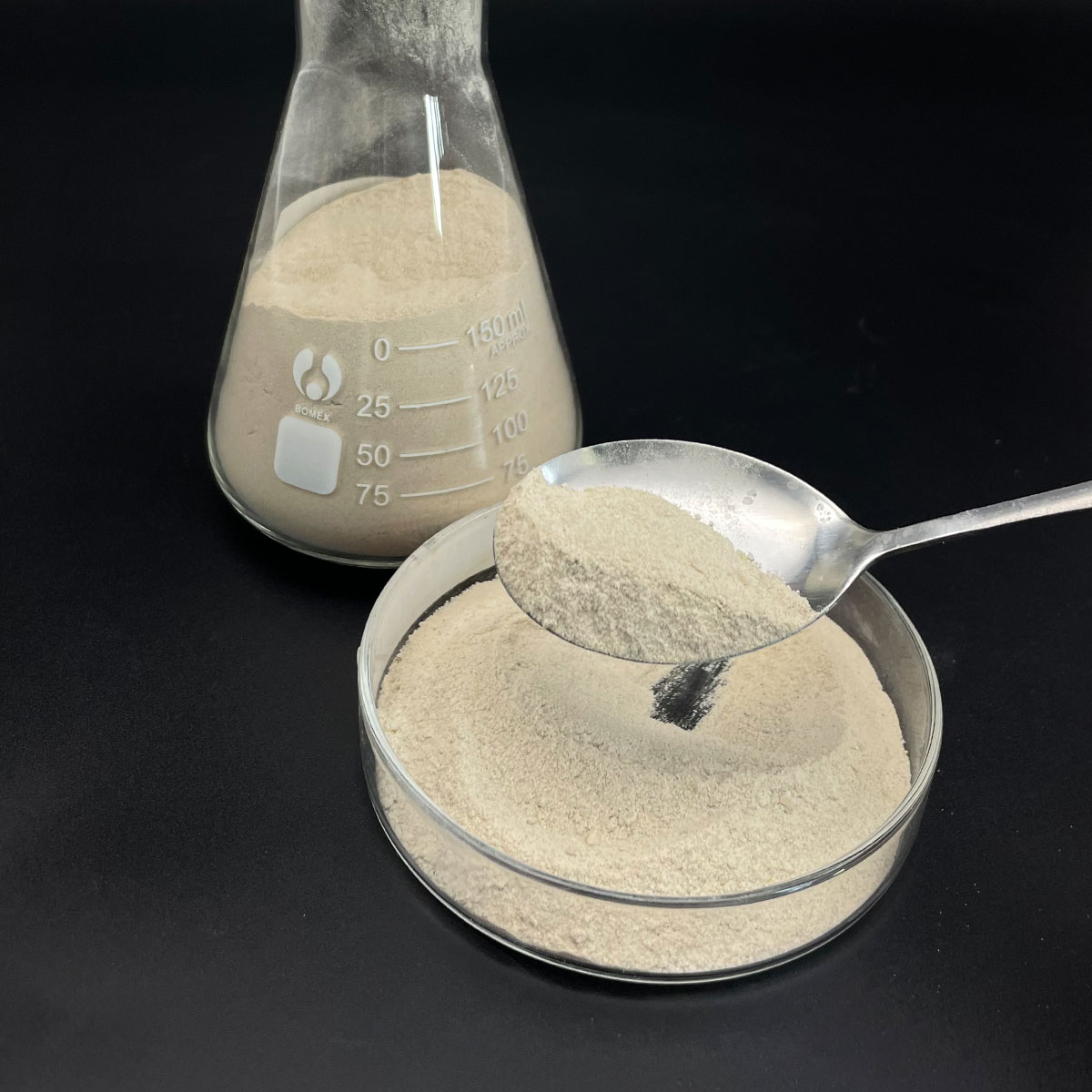

Redispersible Polymer Powder (RDP) is a crucial chemical additive made use of in building and construction products. It enhances the performance of mortar adhesives and concrete admixtures. The powder is made from ethylene-vinyl acetate (EVA) or comparable polymers. These materials create a flexible movie when mixed with water. RDP looks like a white free-flowing powder. The fragment dimension varies from 80 to 200 mesh. This great size makes certain even distribution in completely dry blends. Wetness web content remains below 2%. Reduced moisture stops clumping throughout storage space. The pH degree is neutral, between 6 and 8. This makes it suitable with concrete and various other alkaline parts.

RDP boosts bond in mortar and concrete. It bonds well with different substrates like bricks, ceramic tiles, or wood. The powder boosts adaptability. This lowers splitting under stress and anxiety or temperature adjustments. Water resistance improves considerably. Dealt with materials stand up to rain or humidity better. Resilience expands the lifespan of building tasks. Workability throughout application is smoother. RDP allows less complicated dispersing and shaping of mortars.

The powder does dependably in different climates. It stays secure in high or low temperature levels. Blending RDP is simple. A proportion of 1-3% by weight of dry mix is normal. It mixes well with concrete, sand, and various other additives like cellulose ether. No unique tools is required.

Usual applications include floor tile adhesives, outside insulation systems, and repair work mortars. RDP is used in self-leveling flooring substances. It reinforces waterproofing coatings and plastering products. The powder is excellent for tasks needing high mechanical toughness. It reduces contraction throughout curing.

Storage needs a dry, great environment. Maintain bags secured to stay clear of dampness absorption. Service life is up to one year under correct conditions. RDP meets international standards for construction chemicals. It is safe and risk-free for handling with fundamental safety equipment.

The product provides cost efficiency. Small amounts deliver obvious enhancements. Building contractors attain better results with much less product waste. RDP is commonly made use of in domestic and commercial building and construction. Its versatility makes it a preferred option for modern-day building requirements.

(Redispersible Polymer Powder Chemical Rdp for Mortar Adhesives Concrete Admixture)

Applications of Redispersible Polymer Powder Chemical Rdp for Mortar Adhesives Concrete Admixture

Redispersible Polymer Powder (RDP) is a vital material used in building chemicals. It is made from polymer materials refined into powder form. When blended with water, RDP re-emulsifies, forming a flexible film that boosts efficiency in mortar adhesives and concrete admixtures.

In mortar adhesives, RDP boosts dampness between surfaces and building materials. It assists mortar bond far better to ceramic tiles, blocks, or insulation boards. The powder increases flexibility, enabling the sticky to manage movement or temperature adjustments without breaking. RDP additionally boosts water resistance, stopping dampness damage in wet locations like shower rooms. It decreases contraction during drying out, making sure a stronger, longer-lasting bond.

For concrete admixtures, RDP upgrades workability and resilience. It makes fresh concrete much easier to mix and apply while reducing water web content. This brings about higher stamina and less cracks as the concrete hardens. The polymer film created by RDP fills up small voids in the concrete framework, boosting resistance to use, chemicals, and weather condition. Builders make use of RDP-modified concrete in floors, bridges, or high-traffic areas where sturdiness issues.

RDP works well in repair mortars for fixing cracks or damaged structures. It strengthens the mortar’s grip on old surfaces and prevents future splits. Tile adhesives with RDP hold floor tiles firmly, even under heavy use or resonance. The powder likewise acts as a thickener, helping mortars stick up and down without gliding.

RDP boosts water retention in blends, letting cement hydrate properly for full toughness advancement. It is compatible with various other additives like cellulose ethers or air-entraining representatives. Contractors value RDP’s very easy mixing and lengthy handling time, which streamlines on-site application.

The powder’s convenience makes it a best remedy for modern-day building demands. From residential jobs to commercial complexes, RDP makes sure materials carry out dependably under stress and anxiety. Its function in enhancing bond, flexibility, and durability maintains frameworks steady and extends their life-span.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Redispersible Polymer Powder Chemical Rdp for Mortar Adhesives Concrete Admixture

Redispersible polymer powder (RDP) is a key additive in mortar adhesives and concrete mixes. Here are five common questions about RDP answered. What does RDP do in mortar adhesives? RDP improves adhesion strength and flexibility. It helps mortar stick better to surfaces and reduces cracking. This makes structures more durable. Is RDP safe to mix with cement? Yes. RDP works well with cement and other additives like sand or lime. It blends smoothly without causing harmful reactions. The mix stays stable and easy to apply. Can RDP improve water resistance? RDP forms a flexible film when dried. This film blocks water from soaking into the mortar or concrete. It protects against moisture damage and lengthens the material’s lifespan. How much RDP should be added to a mix? The amount depends on the project. Usually, 1-5% of RDP by weight is mixed into dry materials. Too little reduces effectiveness. Too much may weaken the structure. Follow manufacturer guidelines for best results. How should RDP be stored? Keep RDP in a dry, cool place away from direct sunlight. Seal bags tightly after use. Moisture causes clumping. Proper storage ensures the powder stays usable for up to six months. RDP enhances performance in construction materials. It addresses common issues like weak bonds, brittleness, and water damage. Builders and manufacturers rely on it for reliable, long-lasting results.

(Redispersible Polymer Powder Chemical Rdp for Mortar Adhesives Concrete Admixture)