Overview of Redispersible Polymer Powder Rdp for Skim Coat Plaster Chemical

Polymer surfactants, also known as polymeric surfactants or amphiphilic polymers, are high-molecular-weight compounds that combine the properties of traditional low-molecular-weight surfactants with the unique features of polymers. Unlike small molecule surfactants, polymer surfactants offer enhanced stability, improved solubility, and the ability to form more complex structures such as micelles, hydrogels, and vesicles. These macromolecules find applications across a wide range of industries due to their tailored structures and tunable properties, which allow for precise control over interfacial behavior and solution rheology.

Features of Redispersible Polymer Powder Rdp for Skim Coat Plaster Chemical

-

Molecular Weight and Structure: With a much higher molecular weight, polymer surfactants offer enhanced stability in harsh conditions and over prolonged periods compared to small molecule surfactants.

-

Tunability: The structure of polymer surfactants can be precisely engineered to include different functional groups, monomer sequences, and architectures, allowing for specific interactions and properties.

-

Multifunctionality: Apart from surface activity, they can also provide additional functionalities like thickening, rheology modification, and controlled release capabilities.

-

Self-Assembly: Capable of forming sophisticated self-assembled structures like micelles, hydrogels, and vesicles, which can encapsulate or release active ingredients in a controlled manner.

-

Environmental Compatibility: Many polymer surfactants are designed to be biodegradable and less toxic, making them suitable for eco-friendly applications.

-

Temperature and pH Responsiveness: Some polymer surfactants exhibit responsive behavior to changes in temperature or pH, enabling stimuli-responsive systems.

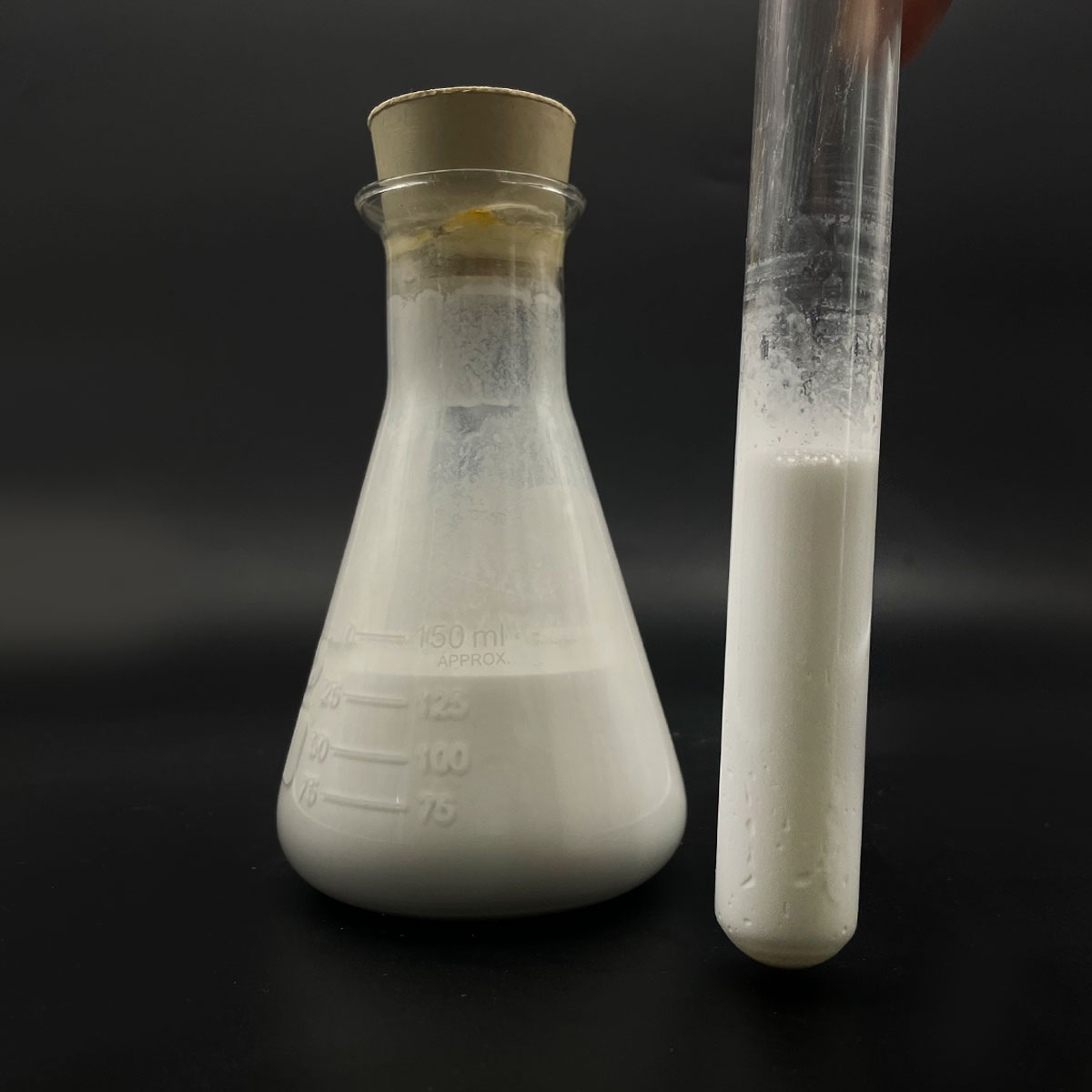

(Redispersible Polymer Powder Rdp for Skim Coat Plaster Chemical)

Specification of Redispersible Polymer Powder Rdp for Skim Coat Plaster Chemical

Redispersible Polymer Powder (RDP) is a vital product made use of in skim layer plaster solutions. The powder enhances performance by boosting bond, versatility, and sturdiness. It is made by spray-drying polymer solutions, usually plastic acetate-based copolymers. The outcome is a free-flowing white powder that quickly redisperses in water.

The primary components consist of polymers like vinyl acetate-ethylene (VAE). These polymers develop a flexible film after drying out. This film binds fragments in the plaster, creating a cohesive framework. The powder has a particle dimension variety of 80-120 mesh. This guarantees smooth combining with cement, plaster, or various other binders. Moisture web content is maintained listed below 2% to avoid clumping. Storage requires an amazing, completely dry atmosphere to preserve stability.

Adding RDP to skim layer plaster boosts workability. It permits much easier application and lowers splitting throughout drying. The polymer enhances bond to substrates like concrete or stonework. This lessens delamination dangers. Versatility is boosted, aiding the plaster withstand temperature adjustments and architectural shifts. Abrasion resistance is enhanced, making surface areas a lot more sturdy. Water resistance is additionally enhanced, reducing damages from moisture exposure.

Regular dose ranges from 1% to 3% by weight of the total mix. Precise amounts depend upon wanted properties and base materials. Compatibility with additives like cellulose ethers or retarders is solid. This enables customization for certain job needs. The powder is non-toxic and complies with worldwide safety and security standards. It fulfills needs for reduced VOC exhausts, suitable for interior and outdoor usage.

Manufacturing follows strict quality assurance to make sure uniformity. Evaluating consists of look for fragment dimension, pH, and ash material. The pH level is neutral, stopping reactions with alkaline substratums. Ash material (not natural components) remains below 15%, preserving polymer effectiveness. Packaging remains in moisture-proof bags, generally 25 kg per bag. Life span depends on twelve month if stored properly.

RDP reduces contraction and enhances fracture resistance in finished surfaces. It adds to a smooth, high-grade surface for wall surfaces or ceilings. The powder is compatible with the majority of building products, including Portland concrete and moisturized lime. Its usage supports much faster application and decreases labor prices.

(Redispersible Polymer Powder Rdp for Skim Coat Plaster Chemical)

Applications of Redispersible Polymer Powder Rdp for Skim Coat Plaster Chemical

Redispersible Polymer Powder (RDP) is a crucial active ingredient in skim coat plaster formulas. It boosts efficiency and sturdiness. Skim layer plaster is made use of to develop smooth surfaces on wall surfaces and ceilings. RDP boosts the plaster’s adhesion to various substrates. This makes sure the finishing stays firmly affixed to concrete, brick, or existing plaster. The powder is mixed right into completely dry mortar blends. When water is included, RDP redisperses, forming a versatile polymer movie. This movie binds the plaster elements together.

RDP enhances the adaptability of skim coat plaster. It minimizes splitting brought on by temperature adjustments or architectural shifts. The polymer film absorbs stress and anxiety. This prevents fractures from forming on the surface. Water resistance is another benefit. RDP reduces the plaster’s porosity. Moisture infiltration is reduced. This safeguards wall surfaces from damages in moist atmospheres.

Toughness is important for skim coat plaster. RDP improves abrasion resistance. The surface stands up to everyday wear and tear. Influence resistance is also enhanced. The plaster stays intact also under minor physical anxiety. RDP ensures long-lasting efficiency. Upkeep requirements are minimized.

Workability during application issues. RDP acts as a lube. It makes the plaster mix simpler to spread out. Service providers achieve a smooth finish with less effort. The powder also prolongs open time. Adjustments can be made before the plaster sets. This works in big or complex jobs.

RDP sustains uniform drying out. Shrinking is lessened. Cracks from fast drying out are prevented. The last surface area remains also and aesthetically regular. Compatibility with ingredients like cellulose ethers or defoamers is high. RDP integrates smoothly right into existing solutions.

Price performance is a useful benefit. RDP decreases product waste. The improved efficiency reduces long-lasting repair expenditures. Contractors get a trustworthy item. Homeowner gain from lasting outcomes.

Environmental elements are considered. RDP is free from hazardous solvents. It satisfies modern safety and security standards. Interior air quality is not compromised. Lasting building and construction techniques are supported.

RDP’s duty in skim layer plaster is clear. It attends to adhesion, adaptability, water resistance, sturdiness, and workability. These properties ensure high-quality coatings. Building and construction tasks obtain performance and dependability.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Redispersible Polymer Powder Rdp for Skim Coat Plaster Chemical

(Redispersible Polymer Powder Rdp for Skim Coat Plaster Chemical)