Overview of Surfactant for Hydraulic Fracturing Stimulation Polymer Fracturing Fluid System Surface Tention and Interfacial Tention Reduction

Polymer surfactants, also known as polymeric surfactants or amphiphilic polymers, are high-molecular-weight compounds that combine the properties of traditional low-molecular-weight surfactants with the unique features of polymers. Unlike small molecule surfactants, polymer surfactants offer enhanced stability, improved solubility, and the ability to form more complex structures such as micelles, hydrogels, and vesicles. These macromolecules find applications across a wide range of industries due to their tailored structures and tunable properties, which allow for precise control over interfacial behavior and solution rheology.

Features of Surfactant for Hydraulic Fracturing Stimulation Polymer Fracturing Fluid System Surface Tention and Interfacial Tention Reduction

-

Molecular Weight and Structure: With a much higher molecular weight, polymer surfactants offer enhanced stability in harsh conditions and over prolonged periods compared to small molecule surfactants.

-

Tunability: The structure of polymer surfactants can be precisely engineered to include different functional groups, monomer sequences, and architectures, allowing for specific interactions and properties.

-

Multifunctionality: Apart from surface activity, they can also provide additional functionalities like thickening, rheology modification, and controlled release capabilities.

-

Self-Assembly: Capable of forming sophisticated self-assembled structures like micelles, hydrogels, and vesicles, which can encapsulate or release active ingredients in a controlled manner.

-

Environmental Compatibility: Many polymer surfactants are designed to be biodegradable and less toxic, making them suitable for eco-friendly applications.

-

Temperature and pH Responsiveness: Some polymer surfactants exhibit responsive behavior to changes in temperature or pH, enabling stimuli-responsive systems.

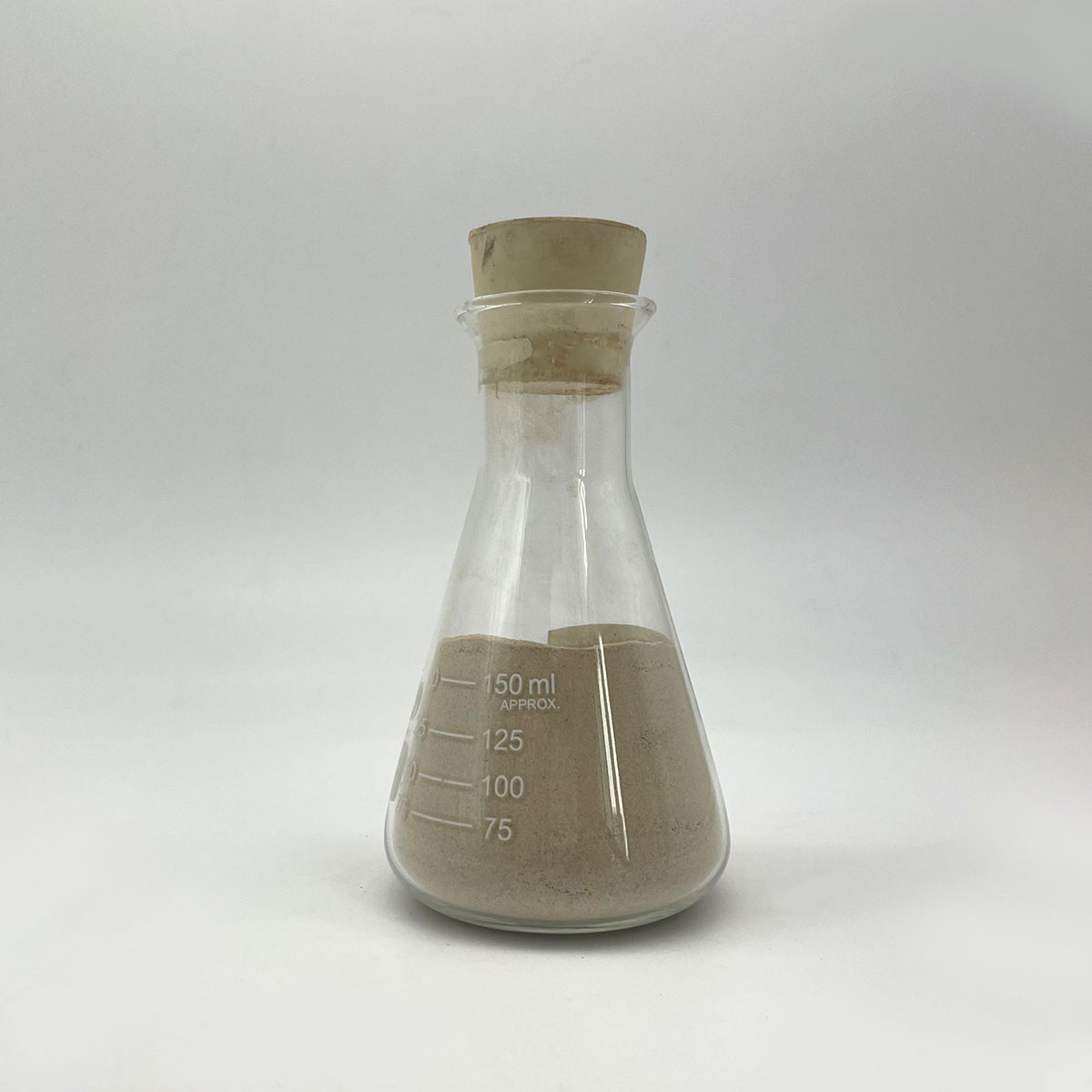

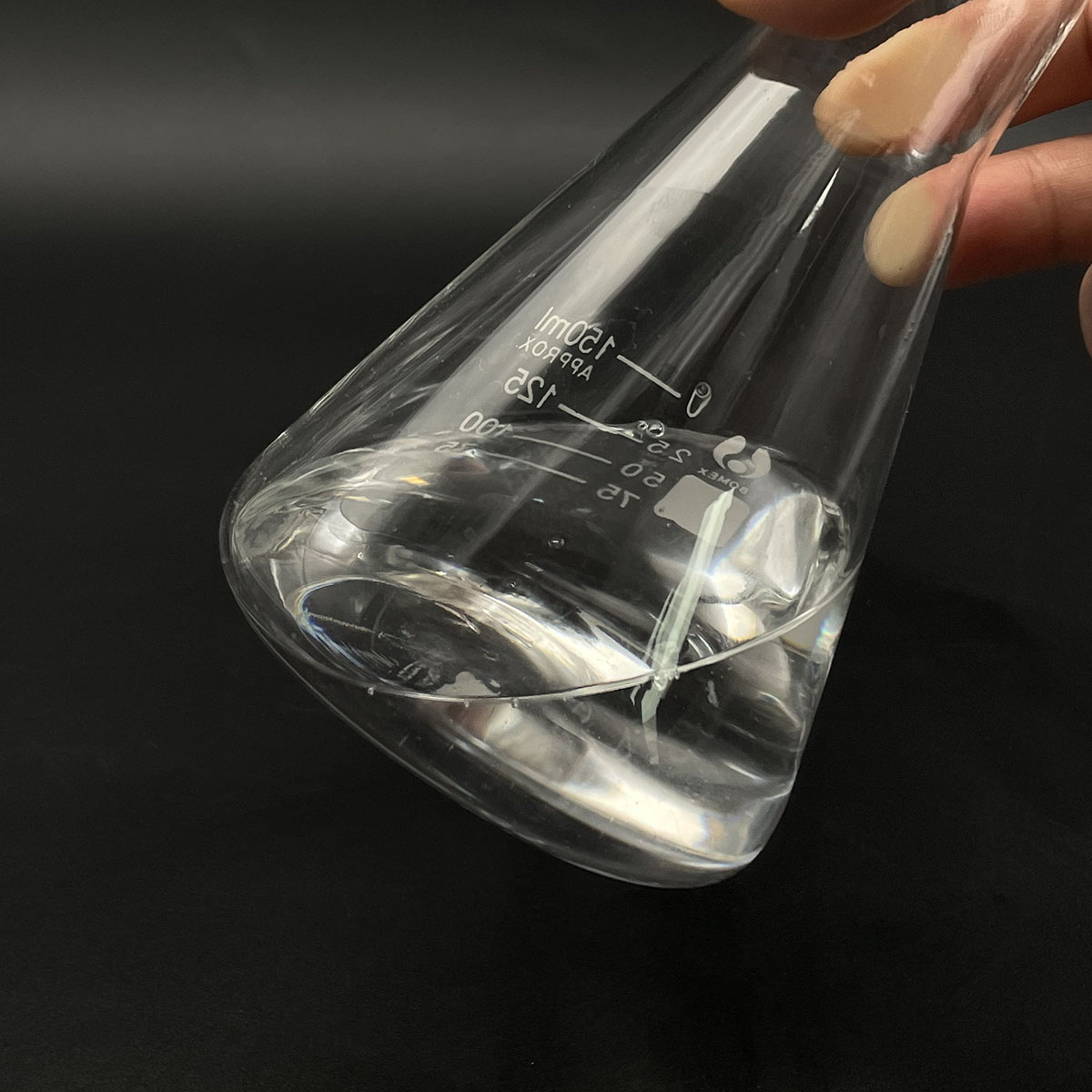

(Surfactant for Hydraulic Fracturing Stimulation Polymer Fracturing Fluid System Surface Tention and Interfacial Tention Reduction)

Specification of Surfactant for Hydraulic Fracturing Stimulation Polymer Fracturing Fluid System Surface Tention and Interfacial Tention Reduction

Surfactant for hydraulic fracturing excitement polymer fracturing liquid systems is designed to lower surface tension and interfacial stress in oil and gas storage tanks. This product improves fluid efficiency and makes the most of hydrocarbon recovery during hydraulic fracturing procedures. The surfactant works by damaging the forces in between storage tank fluids and rock surface areas. This permits fracturing fluids to spread out more uniformly and pass through much deeper into formation pores.

The surfactant works at concentrations in between 0.1% and 0.5% in many fracturing fluid formulations. It keeps stability in high-temperature environments approximately 300 ° F (149 ° C) and high-salinity conditions surpassing 200,000 ppm total liquified solids. These properties make sure reliable efficiency in difficult downhole setups. The item lowers surface area stress to below 30 mN/m and interfacial tension to under 1 mN/m. These values assist stop fluid trapping in reservoir pores and boost post-fracturing fluid flowback.

Compatibility with common fracturing liquid additives is crucial. The surfactant incorporates efficiently with guar periodontal, polyacrylamide, and other viscosifying representatives. It does not conflict with crosslinkers or breakers in the system. The solution resins remain steady during blending and pumping operations. This avoids premature thickness loss or gel development problems.

Environmental and security criteria are prioritized. The surfactant fulfills OSHA needs for dealing with and storage space. It consists of no unstable natural substances or restricted compounds. Biodegradability testing verifies minimal environmental impact. Functional safety and security is enhanced through low poisoning degrees and non-corrosive residential or commercial properties.

Area applications show boosted production rates in tight sandstone and shale formations. The surfactant allows much better liquid distribution within fracture networks. This brings about higher contact areas between the wellbore and reservoir. Operators report improved lots healing portions and reduced water clog results. Personalized formulas deal with certain reservoir conditions like low permeability or high clay web content. Adjustments to focus ratios and additive combinations enhance efficiency for different geological settings.

(Surfactant for Hydraulic Fracturing Stimulation Polymer Fracturing Fluid System Surface Tention and Interfacial Tention Reduction)

Applications of Surfactant for Hydraulic Fracturing Stimulation Polymer Fracturing Fluid System Surface Tention and Interfacial Tention Reduction

Surfactants play a vital function in hydraulic fracturing fluid systems. They improve efficiency by minimizing surface area stress and interfacial tension. Hydraulic fracturing depends on polymer-based fluids to create cracks in rock developments. These liquids lug proppants to hold cracks open. Surface area stress decrease assists the fluid spread evenly via the fractures. Without this, the liquid could not reach all locations. Interfacial tension reduction takes place between the fracturing fluid and hydrocarbons in the tank. Lower interfacial tension permits oil and gas to flow even more freely.

Surfactants aid distribute the fracturing liquid evenly. This guarantees cracks stay open and proppants remain in location. Irregular liquid distribution can bring about bad fracture networks. Surfactants stop this by making the fluid wet rock surface areas better. They also assist the liquid blend with hydrocarbons trapped in the rock. This mixing breaks up obstructions and enhances resource recovery.

Fracturing liquids commonly leave residue in the storage tank after the task. Surfactants lower this trouble. They aid fluids flow back to the wellbore during cleanup. This lessens damage to the tank’s leaks in the structure. Efficient clean-up boosts manufacturing prices and extends well life.

Surfactants address problems like water blockage. Water-based liquids can catch water in small pores. This obstructs oil and gas circulation. Lowering surface tension allows trapped water retreat. Surfactants also maintain the fluid under high pressure and temperature level. They prevent foaming or emulsification that could disrupt operations.

Compatibility with other ingredients matters. Surfactants work with gelling representatives and friction reducers. They do not interfere with the fluid’s viscosity or proppant transport. This equilibrium makes sure the liquid performs reliably downhole.

Environmental factors are essential. Modern surfactants are designed to be naturally degradable. They lower environmental effect without compromising efficiency. Laws demand much safer chemicals. Surfactants satisfy these requirements while keeping efficiency.

Operators take advantage of reduced prices. Much better fluid performance implies much less chemical use. Improved manufacturing prices balance out first expenses. Surfactants make hydraulic fracturing a lot more sustainable and effective.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Surfactant for Hydraulic Fracturing Stimulation Polymer Fracturing Fluid System Surface Tention and Interfacial Tention Reduction

What is a surfactant in a polymer fracturing fluid system? It is a chemical added to hydraulic fracturing fluids. It lowers surface tension. It lowers interfacial tension between fluids and rocks. This helps fracturing fluids spread evenly through the reservoir. It helps trapped oil and gas escape more easily.

Why is reducing surface tension important in hydraulic fracturing? Lower surface tension lets fluids enter small rock fractures. This expands the area contacted by the fluid. Pressure is distributed more effectively. Rocks fracture more thoroughly. Oil and gas flow out faster.

How does the surfactant lower interfacial tension? Surfactant molecules gather at the boundary between oil and water. This breaks down the barrier keeping them apart. Oil or gas separates from water quickly. More hydrocarbons are recovered. It prevents buildup blocking the fractures.

What benefits do surfactants offer in fracturing operations? Fluids return to the surface smoothly after fracturing. Less energy is used to pump fluids up. Less residual fluid remains underground. Rock permeability stays high. Water-related damage to the reservoir is reduced. Production rates improve.

How do you choose the right surfactant for a fracturing job? Check the reservoir’s temperature range. Test under expected pressure conditions. Analyze the water’s mineral content. Confirm it mixes well with other additives. Meet local environmental standards. Run lab trials to verify performance. Adjust based on the well’s specific geology.

(Surfactant for Hydraulic Fracturing Stimulation Polymer Fracturing Fluid System Surface Tention and Interfacial Tention Reduction)