Overview of Textile Pretreatment Auxiliaries Anionic Pretreatment Surfactants Derivatives of Alcohol or Alcohol Ether

Anionic surfactants are a class of surface-active agents characterized by a negatively charged hydrophilic head group when dissolved in water. This charge arises from the presence of a sulfate, sulfonate, phosphate, or carboxylate group. They are among the most widely used surfactants due to their effective cleaning properties, foaming capacity, and broad compatibility with other formulation ingredients. Anionic surfactants find extensive application across industries, including personal care, household cleaning, textiles, and industrial processes.

Features of Textile Pretreatment Auxiliaries Anionic Pretreatment Surfactants Derivatives of Alcohol or Alcohol Ether

-

Negative Charge: The anionic head group imparts water solubility and enables interaction with positively charged surfaces or particles.

-

Detergency: Exceptional at removing dirt, grease, and oils due to their strong polarity and ability to penetrate and disrupt these substances.

-

Foaming Properties: Many anionic surfactants generate stable and abundant foam, making them ideal for applications where lather is desired.

-

Cost-Effectiveness: They are often less expensive than nonionic, cationic, or amphoteric surfactants due to the abundance of raw materials and established production processes.

-

Compatibility: Can be combined with other surfactants to enhance performance or adjust properties, although care must be taken to avoid precipitation or incompatibility issues.

-

Environmental Considerations: Some anionic surfactants may pose environmental concerns due to their persistence or toxicity; however, biodegradable options are available.

(Textile Pretreatment Auxiliaries Anionic Pretreatment Surfactants Derivatives of Alcohol or Alcohol Ether)

Specification of Textile Pretreatment Auxiliaries Anionic Pretreatment Surfactants Derivatives of Alcohol or Alcohol Ether

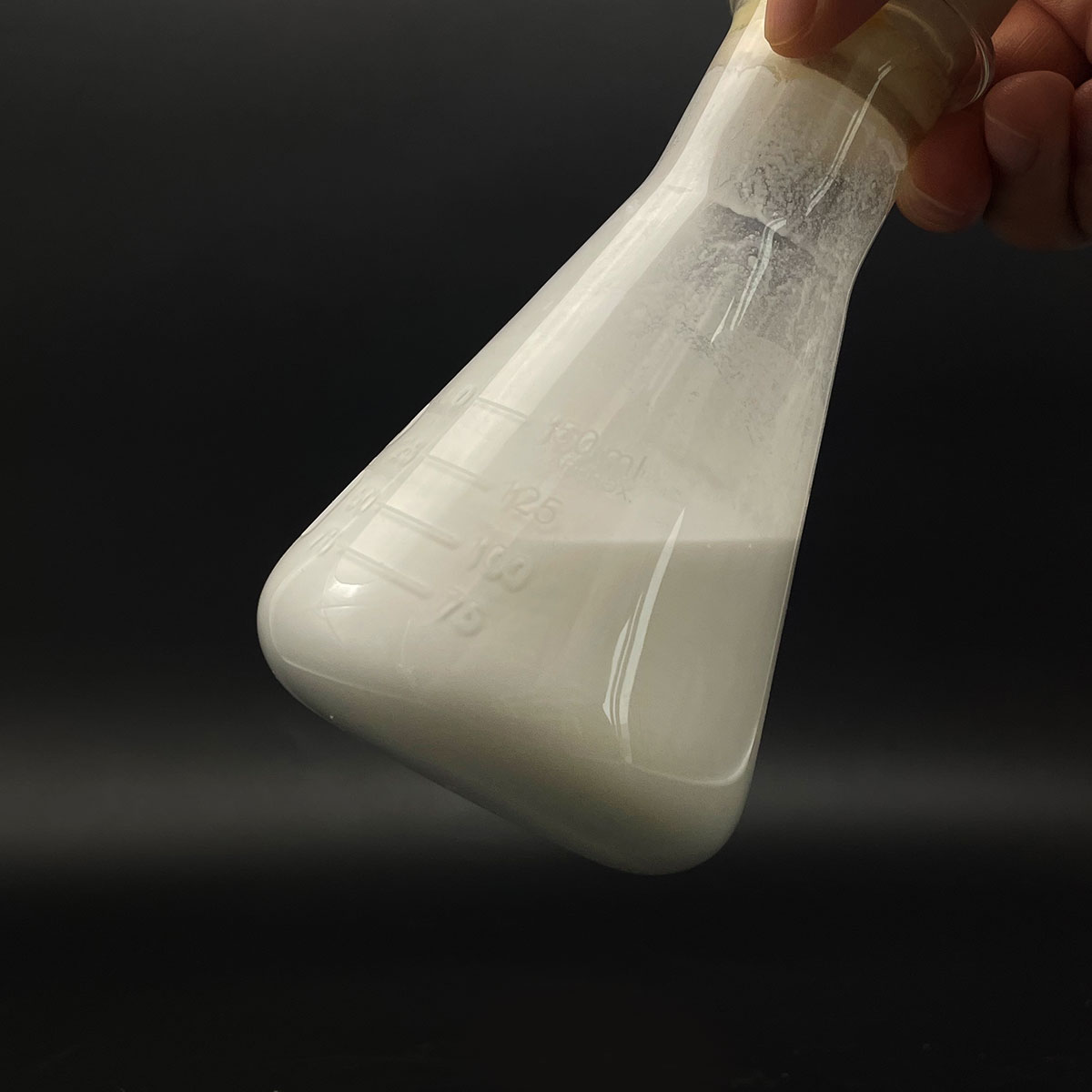

Fabric pretreatment accessories anionic pretreatment surfactants derived from alcohol or alcohol ether are specialized chemicals used in material handling. These items prepare textiles for coloring or completing by getting rid of contaminations. They work on natural and artificial fibers. The major parts include sulfates or sulfonates of alcohol or alcohol ether. These derivatives produce strong cleaner effective in breaking down oils, waxes, or dirt caught in fibers.

The surfactants function as wetting representatives. They minimize water’s surface area tension to aid it spread uniformly throughout textile surface areas. This speeds up the infiltration of various other chemicals into the material. The products are steady in alkaline conditions usual in pretreatment baths. They preserve performance throughout a range of temperature levels.

Key features include high emulsification power. This enables efficient removal of non-water-soluble contaminants. The surfactants stop redeposition of pollutants onto textiles during cleaning. They work with enzymes and oxidizers used in pretreatment actions. Reduced foam generation guarantees smooth procedure in high-speed machinery.

Applications consist of desizing, combing, and lightening processes. In desizing, they assist eliminate starch-based sizing representatives. Throughout scouring, they eliminate natural fats or waxes from cotton. They help in stabilizing hydrogen peroxide during whitening. The surfactants boost textile absorbency for also color uptake later on.

Performance benefits include constant outcomes across various textile kinds. They minimize processing time by accelerating chemical reactions. Energy financial savings come from lower necessary temperatures. The items are eco-friendly. They satisfy ecological laws for wastewater discharge.

Compatibility reaches most standard pretreatment tools. Dose varies based on water firmness or contamination degrees. Testing is advised to maximize focus. Storage space requires completely dry conditions at room temperature. Direct sunlight direct exposure should be prevented.

Product packaging choices include drums or intermediate bulk containers. Life span generally goes beyond twelve month. Security standards include using gloves and safety glasses during handling. Proper air flow is essential in storage areas.

(Textile Pretreatment Auxiliaries Anionic Pretreatment Surfactants Derivatives of Alcohol or Alcohol Ether)

Applications of Textile Pretreatment Auxiliaries Anionic Pretreatment Surfactants Derivatives of Alcohol or Alcohol Ether

Textile pretreatment auxiliaries play a key role in preparing fabrics for coloring or completing. Anionic pretreatment surfactants stemmed from alcohol or alcohol ether are widely utilized in this stage. These surfactants assist remove impurities from raw textiles. Natural oils, waxes, and dirt typically stay with fibers during manufacturing. Anionic surfactants damage down these substances effectively. They work by lowering surface tension in water. This allows cleansing representatives to penetrate fabric more conveniently.

These surfactants make materials take in far better. Improved absorbency guarantees dyes and finishes spread out equally. Uneven dyeing triggers shade patches or weak tones. Pretreatment with alcohol-based surfactants avoids this. The procedure likewise reinforces fabric quality. Fibers become softer and a lot more constant. This is important for preserving material honesty during later actions.

Alcohol ether by-products are steady in severe conditions. They do well in high-temperature washing or acidic settings. Fabric mills make use of heavy machinery for pretreatment. Surfactants must stand up to mechanical tension. Anionic kinds hold up far better than some alternatives. Their chemical structure helps them blend with various other agents. Compatibility reduces the threat of unwanted responses. This simplifies the pretreatment process.

An additional benefit is their ecological effect. Many anionic surfactants damage down faster after disposal. They generate fewer hazardous by-products compared to non-biodegradable choices. Manufacturing facilities deal with rigorous laws on wastewater. Making use of these surfactants helps meet environment-friendly requirements.

Expense efficiency issues in textile production. Anionic alcohol ether surfactants call for smaller doses for effective results. Reduced usage cuts chemical costs. They also reduce processing time. Faster pretreatment speeds up total production.

These surfactants adapt to different fabric kinds. Cotton, polyester, and blends demand unique pretreatment approaches. Anionic variants adjust to varying fiber chemistries. This flexibility sustains diverse fabric making demands.

Fabric mills prioritize constant results. Anionic pretreatment surfactants make sure trustworthy contamination removal. Clean textiles enhance the performance of dyes and layers. This results in higher-quality final product.

The function of these surfactants prolongs past cleaning. They prepare materials to communicate ideally with later treatments. Proper pretreatment minimizes issues in completed textiles. This minimizes waste and boosts efficiency.

Anionic alcohol-based surfactants stay a functional choice for modern fabric processing. Their performance, flexibility, and expense advantages make them vital in industrial setups.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Textile Pretreatment Auxiliaries Anionic Pretreatment Surfactants Derivatives of Alcohol or Alcohol Ether

“Textile pretreatment auxiliaries anionic pretreatment surfactants derivatives of alcohol or alcohol ether – what are they?” These chemicals are special cleaning agents made from alcohol or alcohol ether. They help prepare fabrics for dyeing or finishing by removing dirt, oils, or other impurities. Their anionic charge makes them work well in water-based processes.

“Why use these surfactants in textile pretreatment?” They break down stubborn stains or grease on fabrics quickly. They prevent impurities from sticking back to the fabric during washing. This ensures the material stays clean and ready for the next steps like dyeing. They also work smoothly with other pretreatment chemicals.

“What benefits do these surfactants offer compared to others?” They are strong cleaners even in hard water. They stay stable at high temperatures or extreme pH levels. This reduces the risk of damaging delicate fabrics. They are biodegradable, making them safer for the environment than some traditional options.

“Are these surfactants safe for workers and machinery?” Proper handling is key. They are non-toxic when used as directed. Workers should wear gloves and goggles to avoid skin or eye contact. They do not corrode machines, but regular cleaning of equipment is advised to prevent residue buildup.

“How to apply these surfactants in pretreatment processes?” Mix them with water first. The usual dosage is 1-3% of the fabric weight. Adjust based on how dirty the fabric is. Apply them during pre-washing or soaking stages. Ensure water temperature stays between 40-60°C for best results. Rinse fabrics thoroughly after treatment to remove any leftover surfactant.

(Textile Pretreatment Auxiliaries Anionic Pretreatment Surfactants Derivatives of Alcohol or Alcohol Ether)