Overview of Toynol Foamic-021 Molecular Surfactant Eliminating stubborn foam caused by anionic substance

Anionic surfactants are a class of surface-active agents characterized by a negatively charged hydrophilic head group when dissolved in water. This charge arises from the presence of a sulfate, sulfonate, phosphate, or carboxylate group. They are among the most widely used surfactants due to their effective cleaning properties, foaming capacity, and broad compatibility with other formulation ingredients. Anionic surfactants find extensive application across industries, including personal care, household cleaning, textiles, and industrial processes.

Features of Toynol Foamic-021 Molecular Surfactant Eliminating stubborn foam caused by anionic substance

-

Negative Charge: The anionic head group imparts water solubility and enables interaction with positively charged surfaces or particles.

-

Detergency: Exceptional at removing dirt, grease, and oils due to their strong polarity and ability to penetrate and disrupt these substances.

-

Foaming Properties: Many anionic surfactants generate stable and abundant foam, making them ideal for applications where lather is desired.

-

Cost-Effectiveness: They are often less expensive than nonionic, cationic, or amphoteric surfactants due to the abundance of raw materials and established production processes.

-

Compatibility: Can be combined with other surfactants to enhance performance or adjust properties, although care must be taken to avoid precipitation or incompatibility issues.

-

Environmental Considerations: Some anionic surfactants may pose environmental concerns due to their persistence or toxicity; however, biodegradable options are available.

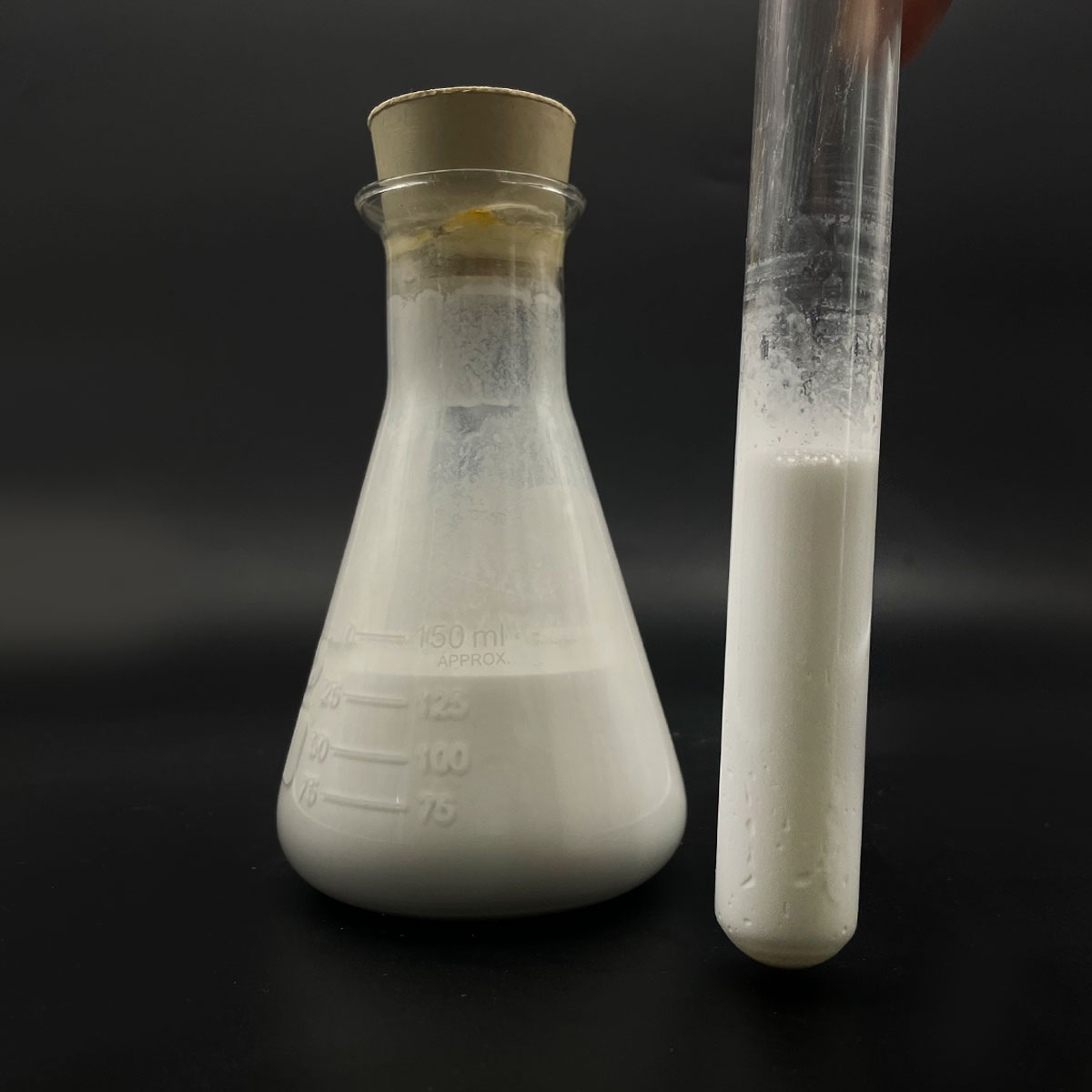

(Toynol Foamic-021 Molecular Surfactant Eliminating stubborn foam caused by anionic substance)

Specification of Toynol Foamic-021 Molecular Surfactant Eliminating stubborn foam caused by anionic substance

Toynol Foamic-021 Molecular Surfactant takes on persistent foam caused by anionic substances. This product functions fast. It breaks down foam rapidly. It takes care of tough commercial atmospheres. The formula targets foam at a molecular degree. It stops foam from creating once again.

The item is a clear liquid. It mixes quickly with water. The focus is high. A small amount gets the job done. Usage 0.1% to 0.5% by weight. Change based on foam severity. It works in hot or chilly systems. It stays efficient in temperature levels up to 80 ° C. The pH array is 3 to 12. It fits several applications.

Foamic-021 works with most commercial procedures. It does not harm tools. It does not leave residue. It is risk-free for metals, plastics, and rubber. The product is non-flammable. It has reduced volatility. Storage space is simple. Maintain it in a great, completely dry area. Use initial containers. Prevent direct sunlight.

This surfactant fits wastewater therapy. It works in chemical manufacturing. It helps in food processing. It is good for pulp and paper manufacturing. It manages foam in cleaning up representatives. It stops foam in adhesives. It maintains processes. It enhances effectiveness.

The item is non-toxic. It fulfills environmental standards. It breaks down naturally. Disposal follows local laws. Usage protective equipment. Put on handwear covers and goggles. Stay clear of skin contact. Rinse with water if get in touch with occurs.

Foamic-021 can be found in 25kg drums. Smaller sized bundles are readily available. Get in touch with vendors for bulk orders. Life span is 2 years. Examine the tag for production days. Change old stock as needed.

This item cuts downtime. It decreases upkeep prices. It keeps systems running smoothly. Industries trust its integrity. It delivers consistent outcomes. No complex setup is required. Include it straight to the damaged area. Display foam levels. Adjust dose if needed.

Safety and security information sheets are supplied. Technical support is readily available. Reach out for application advice. Share procedure information for customized suggestions. Examination compatibility prior to full-blown usage.

(Toynol Foamic-021 Molecular Surfactant Eliminating stubborn foam caused by anionic substance)

Applications of Toynol Foamic-021 Molecular Surfactant Eliminating stubborn foam caused by anionic substance

Toynol Foamic-021 Molecular Surfactant addresses an important challenge in sectors dealing with persistent foam brought on by anionic materials. Anionic products typically create steady, resilient foam that interferes with processes. Conventional defoamers struggle to damage this foam efficiently. This item provides a reputable service. It targets foam at the molecular level, disrupting the framework developed by anionic surfactants. The result is quick foam collapse and lasting reductions.

Foamic-021 works across numerous conditions. It continues to be efficient in high-temperature atmospheres and extreme pH levels. This adaptability makes it appropriate for markets like wastewater therapy, where foam can hinder purification and oygenation systems. In chemical processing, foam slows manufacturing prices and threats tools damages. The surfactant integrates seamlessly right into these processes without affecting product high quality.

The item requires minimal dose. Small amounts provide solid foam control, lowering functional expenses. It acts quickly, preventing hold-ups in production or therapy cycles. Users see improved efficiency and lowered downtime. Industries like pharmaceuticals take advantage of its safe formulation. It satisfies security standards for applications entailing delicate items or settings.

Agriculture is one more crucial location. Foam problems arise in pesticide and fertilizer production. Foamic-021 makes sure smooth mixing and packaging by eliminating air entrapment. Food handling plants also utilize it to preserve hygiene and constant product texture. The surfactant leaves no deposit, protecting the quality of end products.

Ecological security is a concern. Foamic-021 breaks down naturally, lessening eco-friendly influence. It adheres to worldwide policies for biodegradability. Firms minimize their ecological impact while keeping efficiency.

Alleviate of use is a major benefit. The fluid formulation mixes well with water or natural solvents. No specialized equipment is needed for application. Workers add it directly to influenced systems, seeing outcomes within mins. Storage is straightforward, with steady performance over long periods.

Industries encountering foam-related difficulties locate Foamic-021 vital. Its targeted action versus anionic compounds establishes it besides generic defoamers. The combination of efficiency, security, and flexibility makes it a practical selection for diverse applications.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Toynol Foamic-021 Molecular Surfactant Eliminating stubborn foam caused by anionic substance

What does Toynol Foamic-021 Molecular Surfactant do?

It removes tough foam caused by anionic substances in industrial processes. The product targets foam at a molecular level. It breaks down the chemical structure of foam-forming agents. This stops foam from building up again.

Does it work on all types of anionic substances?

Yes. It is designed to handle common anionic materials like sulfates, sulfonates, and carboxylates. These are found in detergents, cleaners, and wastewater systems. The surfactant adjusts to different pH levels. It stays effective in acidic or alkaline environments.

Is it safe for equipment or surfaces?

The formula is non-corrosive. It works safely on metals, plastics, and rubber parts. Testing is still recommended before full use. Apply a small amount first. Check for reactions like discoloration or residue.

How do I apply Toynol Foamic-021?

Add it directly to the foaming solution. Use during production or after foam appears. Mix it evenly for best results. Spraying or injecting it into systems is also effective. Adjust the method based on foam severity.

How much should I use?

Start with 0.1% to 0.5% of the total solution volume. Increase the dose if foam persists. Overuse might reduce its efficiency. Follow guidelines based on foam type and system size. Track results to find the right balance.

(Toynol Foamic-021 Molecular Surfactant Eliminating stubborn foam caused by anionic substance)