Overview of Wall Putty Skim Coat Additive Vae Redispersible Polymer Powder (Rdp)

Polymer surfactants, also known as polymeric surfactants or amphiphilic polymers, are high-molecular-weight compounds that combine the properties of traditional low-molecular-weight surfactants with the unique features of polymers. Unlike small molecule surfactants, polymer surfactants offer enhanced stability, improved solubility, and the ability to form more complex structures such as micelles, hydrogels, and vesicles. These macromolecules find applications across a wide range of industries due to their tailored structures and tunable properties, which allow for precise control over interfacial behavior and solution rheology.

Features of Wall Putty Skim Coat Additive Vae Redispersible Polymer Powder (Rdp)

-

Molecular Weight and Structure: With a much higher molecular weight, polymer surfactants offer enhanced stability in harsh conditions and over prolonged periods compared to small molecule surfactants.

-

Tunability: The structure of polymer surfactants can be precisely engineered to include different functional groups, monomer sequences, and architectures, allowing for specific interactions and properties.

-

Multifunctionality: Apart from surface activity, they can also provide additional functionalities like thickening, rheology modification, and controlled release capabilities.

-

Self-Assembly: Capable of forming sophisticated self-assembled structures like micelles, hydrogels, and vesicles, which can encapsulate or release active ingredients in a controlled manner.

-

Environmental Compatibility: Many polymer surfactants are designed to be biodegradable and less toxic, making them suitable for eco-friendly applications.

-

Temperature and pH Responsiveness: Some polymer surfactants exhibit responsive behavior to changes in temperature or pH, enabling stimuli-responsive systems.

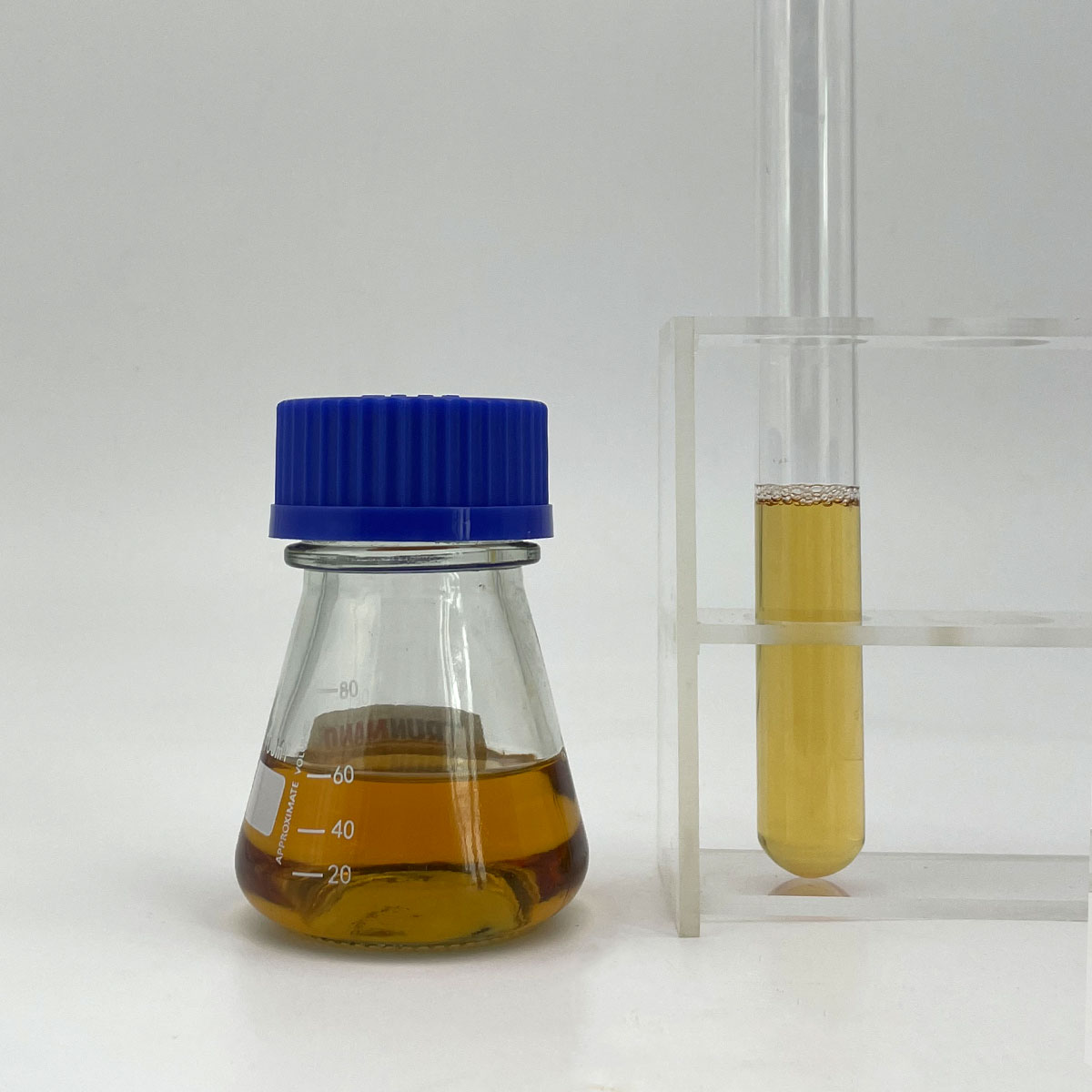

(Wall Putty Skim Coat Additive Vae Redispersible Polymer Powder (Rdp))

Specification of Wall Putty Skim Coat Additive Vae Redispersible Polymer Powder (Rdp)

Wall Putty Skim Coat Additive VAE Redispersible Polymer Powder (RDP) improves the performance of cement-based materials. This powder mixes easily with wall putty or skim coat products. It enhances adhesion, flexibility, water resistance. Builders use it to create smooth, durable surfaces on interior and exterior walls.

The product contains vinyl acetate-ethylene (VAE) copolymer. This material forms a flexible film when dry. It bonds tightly with cement particles. The result is a stronger, crack-resistant finish. The powder works in both new construction and renovation projects.

Key specifications include a white, free-flowing powder appearance. Particle size ranges from 80 to 150 mesh. The pH value stays between 6 and 8. Moisture content remains under 2%. The powder disperses quickly in water. It integrates smoothly with cement, gypsum, or lime-based mixes.

Adding this polymer improves workability. It reduces dust formation during application. The mixture spreads evenly. Drying time shortens. Final surfaces resist peeling, cracking, water damage. It supports coatings like paint or wallpaper.

Typical dosage ranges from 1% to 3% by weight. Exact ratios depend on base material requirements. Higher amounts increase flexibility for high-movement areas. Lower amounts suit standard conditions. Testing small batches first ensures optimal results.

Application areas cover wall putty, skim coats, tile adhesives, exterior insulation systems. It performs well in varying temperatures. Storage requires dry, cool conditions below 25°C. Sealed packaging prevents moisture absorption. Shelf life extends up to 12 months.

The powder complies with international safety standards. It contains no harmful volatile compounds. Users should wear masks during handling. Avoid direct skin contact. Rinse with water if irritation occurs.

Mixing involves adding powder to water gradually. Stir continuously until fully dissolved. Combine with dry materials afterward. Apply within two hours for best adhesion. Cure time depends on humidity and temperature.

(Wall Putty Skim Coat Additive Vae Redispersible Polymer Powder (Rdp))

Applications of Wall Putty Skim Coat Additive Vae Redispersible Polymer Powder (Rdp)

Wall putty skim coat additive VAE redispersible polymer powder (RDP) enhances construction material performance. Builders mix this powder into wall putty to create smooth, durable surfaces. The polymer improves adhesion between the putty and walls. It reduces cracking caused by temperature changes or structural shifts. RDP increases flexibility in the final finish. This helps surfaces handle stress without damage.

Skim coat applications benefit from RDP’s water-resistant properties. The powder forms a protective layer when dry. This layer prevents moisture from seeping into walls. It stops mold growth and surface degradation. RDP also improves workability during application. Contractors spread the mixture evenly with less effort. Drying time shortens without compromising strength.

Tile adhesives gain strength when RDP is added. The powder boosts bonding power between tiles and substrates. It prevents tiles from loosening over time. RDP resists shrinkage during curing. Gaps or hollow spots under tiles become less likely. The adhesive stays stable in humid environments.

Exterior insulation systems use RDP for weatherproofing. The polymer reinforces insulation layers against rain, wind, and UV exposure. It maintains thermal efficiency by preventing cracks. RDP ensures long-term insulation performance. Harsh weather conditions cause minimal wear.

Repair mortars mixed with RDP fix cracks effectively. The powder fills gaps tightly. It bonds well with old and new concrete surfaces. RDP prevents future cracks by distributing stress evenly. Repaired areas blend seamlessly with surrounding structures.

RDP upgrades cement-based renders and plasters. The polymer reduces dusting on finished surfaces. It improves resistance to abrasion and impact. Surfaces stay clean and intact under daily use. RDP allows thin-layer applications without strength loss.

The powder works in self-leveling compounds for floors. It ensures smooth, flat surfaces after drying. RDP prevents uneven settling or bubbling. Floors withstand heavy foot traffic and machinery.

RDP is compatible with various construction materials. It integrates into mixes without complex steps. Builders achieve professional results with minimal training. The powder meets modern construction standards for quality and safety.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Wall Putty Skim Coat Additive Vae Redispersible Polymer Powder (Rdp)

Wall Putty Skim Coat Additive VAE Redispersible Polymer Powder (RDP) is a material used to improve wall coatings. Here are common questions about it.

What is this powder used for? It is mixed with wall putty or skim coat materials. It makes the final surface stronger. It helps prevent cracks. It improves how well the coating sticks to walls.

What benefits does it offer? It increases flexibility in the dried coating. This reduces peeling or breaking over time. It resists water better. This makes walls last longer in damp areas. It helps create smoother finishes.

How is it mixed into wall putty? Add the powder to dry wall putty or cement mixes first. Follow the ratio recommended by the manufacturer. Usually 2-5% of the total mix. Mix dry ingredients thoroughly before adding water. Stir until no lumps remain. Apply the mixture quickly after preparation.

Is it safe to handle? Wear gloves and masks when using it. The powder is non-toxic but can irritate skin or lungs. Keep it away from children. Store it in a dry place. Avoid contact with eyes. Wash hands after use.

How is it different from other additives? It forms a flexible film as it dries. This film binds materials tightly. Regular additives may lack this feature. It works better in changing temperatures. It reduces the risk of shrinkage cracks.

These points cover basic details about the product. Users should always check guidelines provided by suppliers.

(Wall Putty Skim Coat Additive Vae Redispersible Polymer Powder (Rdp))